您所在的位置:

- 上海美言壹泵阀有限公司

- 全国销售热线:

+86 21 5640 2009 - 水泵客服电话:

+86 138 1691 3072 - 阀门客服电话:

+86 1381 6913 072 - 企业电子邮箱:

my1pv@1bengfa.com

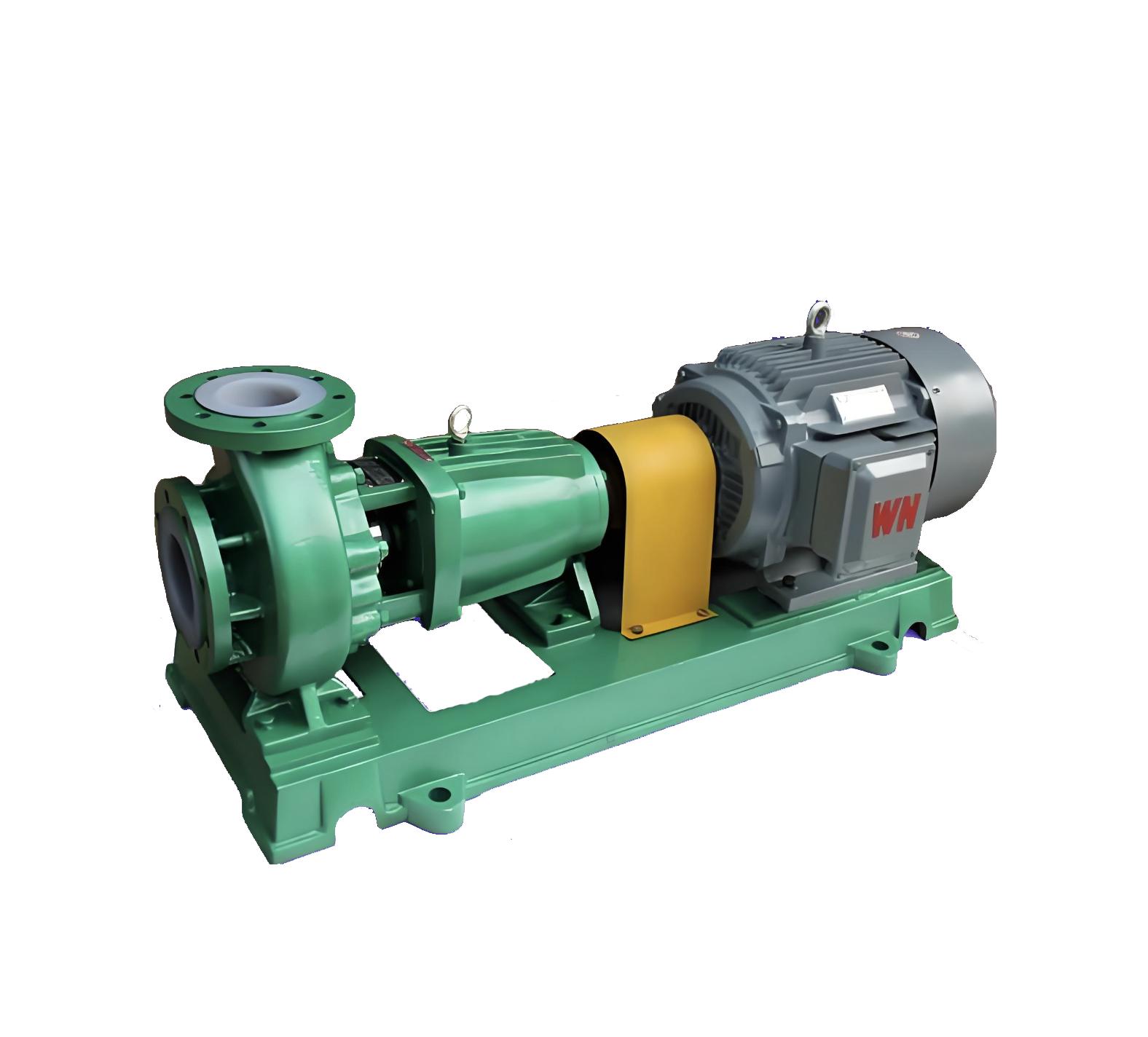

CZ-CZB-CZK标准化工泵

- 品牌:壹泵阀

- 型号:CZ/CZB/CZK

- 压力/扬程:7~160

- 工作温度:-80℃~300℃

- 连接方式:法兰

- 产品名称:CZ-CZB-CZK标准化工泵

- 通径/流量:3.2~1700吨/每小时

- 材质:不锈钢SS304、SS304L、SS316、SS316L

- 驱动方式:电动

- 适用范围:低温或高温液体、腐蚀性液体、含有固体颗粒的液体

- 产品概述

- 性能参数

- 尺寸重量

CZ-CZB-CZK标准化工泵

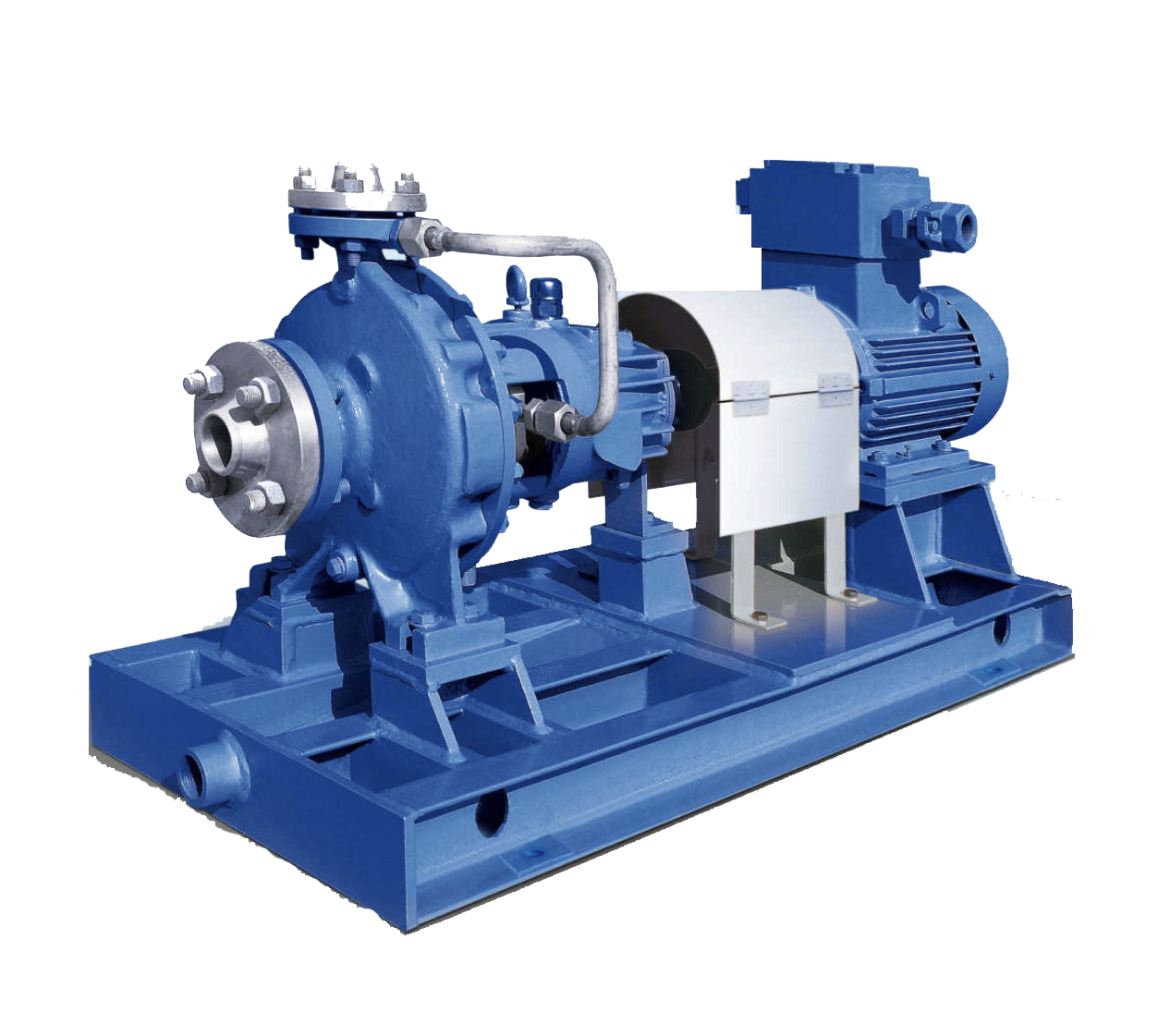

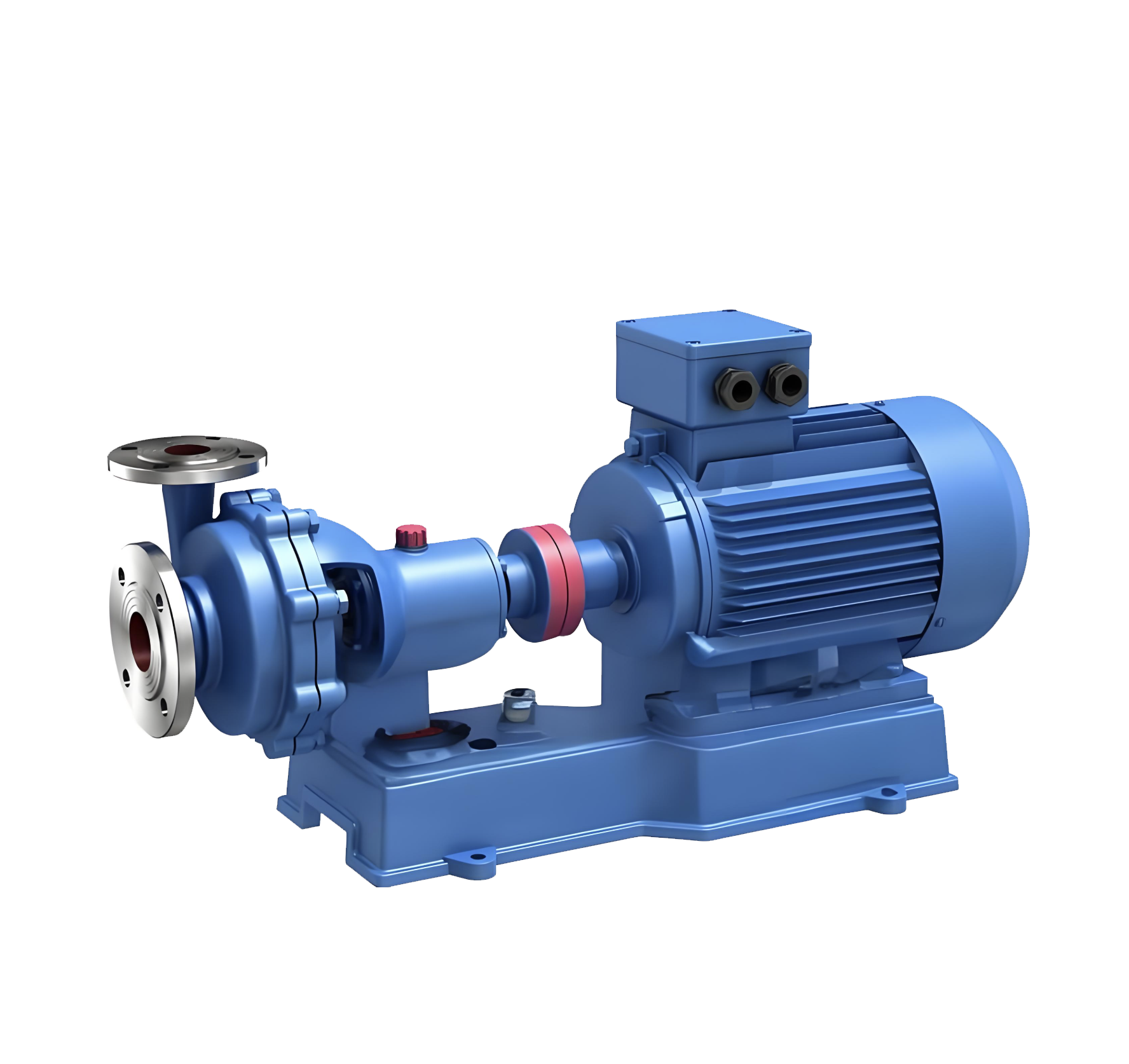

CZ型标准石油化工流程(又称:CZ标准化工泵,型号还分CZB闭式叶轮和CZK开始叶轮)是石油用卧式、单级、单吸冲压离心泵;其尺寸和性能符合DIN24256/ISO2858标准。性能范围包括了 IH系列标准化工泵所有的性能,其效率、气蚀性能等指标均超过IH型不锈钢化工离心泵,可与IH化工泵进行单机互换。CZ标准化工泵主要用于输送低温或高温液体;中性或有腐蚀性液体;清洁或内含有固体颗粒的液。特别适用于: 化学和石油化学工业造纸厂和纸浆业涂装行业(脱脂、磷化、电泳等工序)。

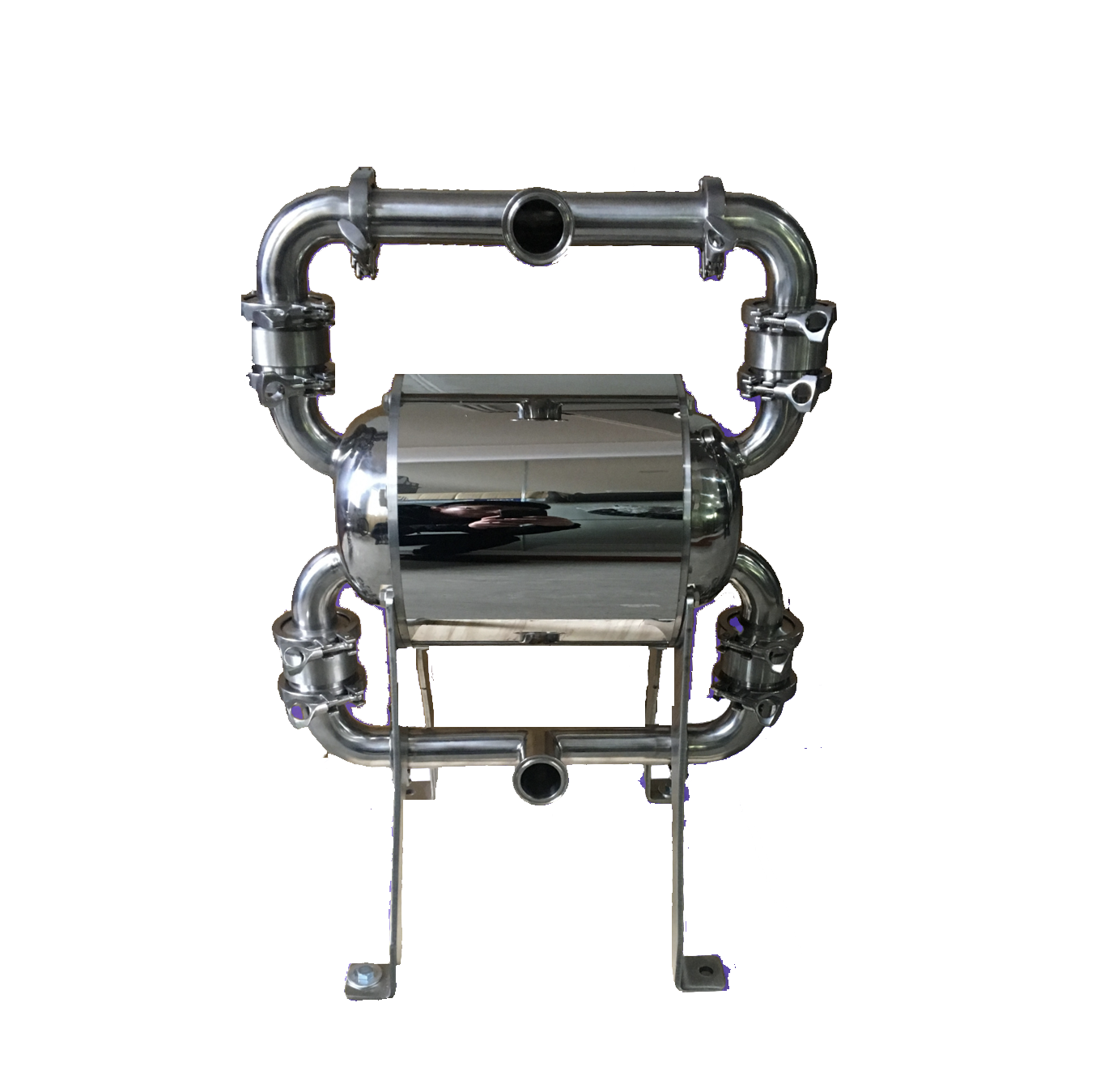

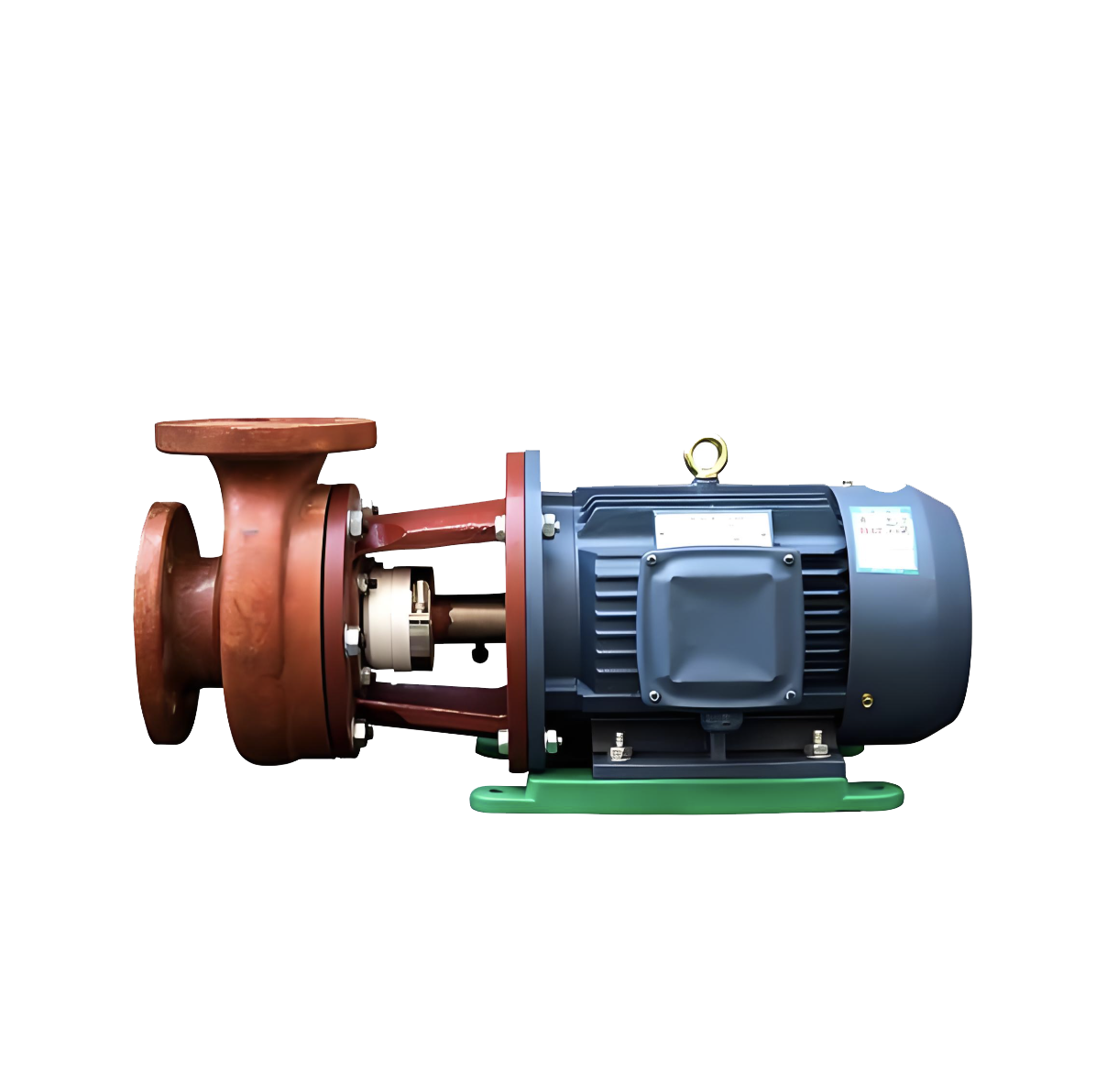

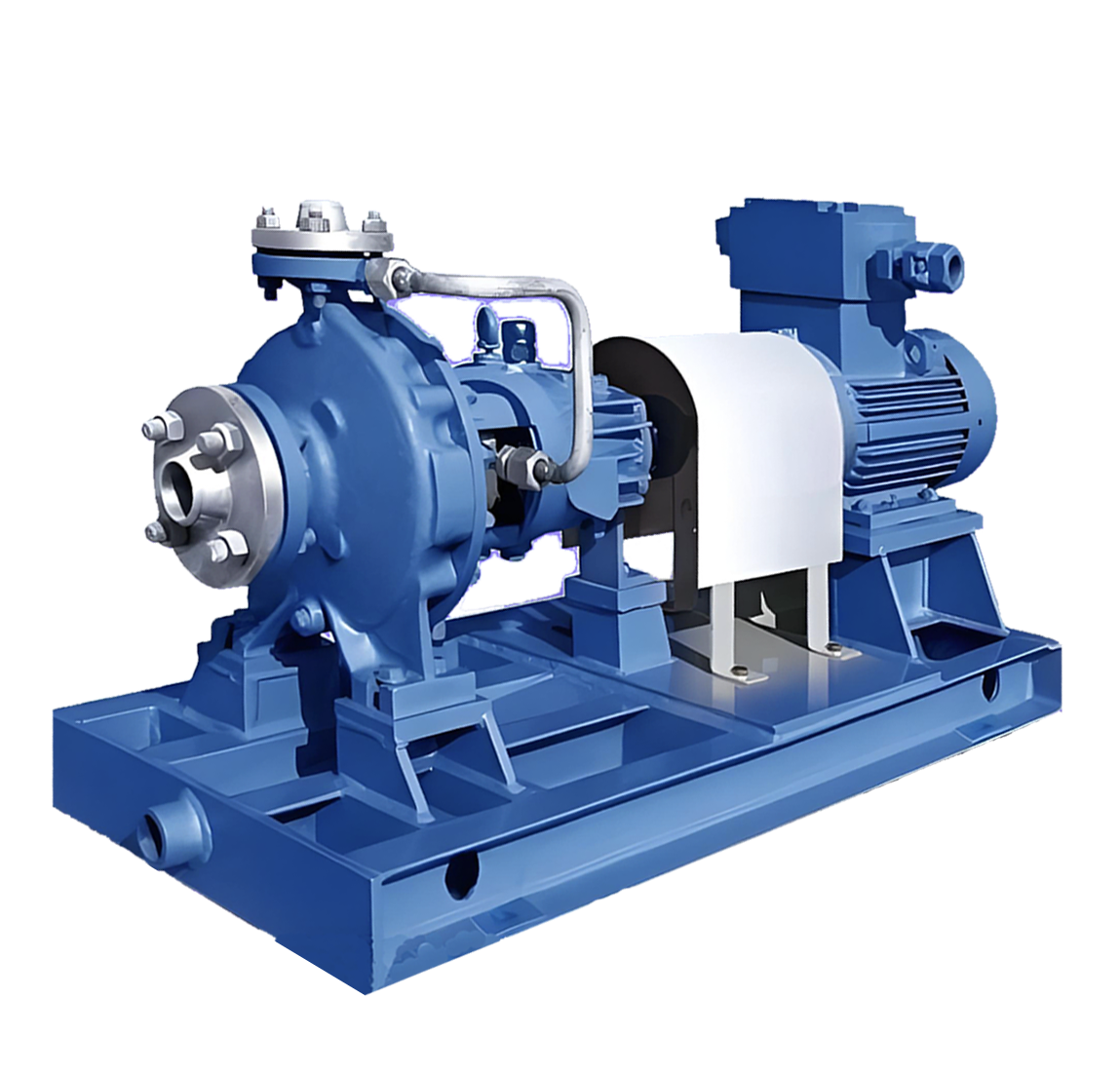

CZ型标准化工流程泵产品图

CZ标准化工泵性能范围

| 流量(Q) 3.2-2000m3/h | 扬程(H) 7-160m |

| 工作压力(P) 2.5MPa | 工作温度(t) -80°C~+300°C |

| 口径DN32-300mm | 转速1450r/min,2900r/min |

| 特性曲线平坦,汽蚀值低,效率高,在不满负荷时,也保持这些特性。 | |

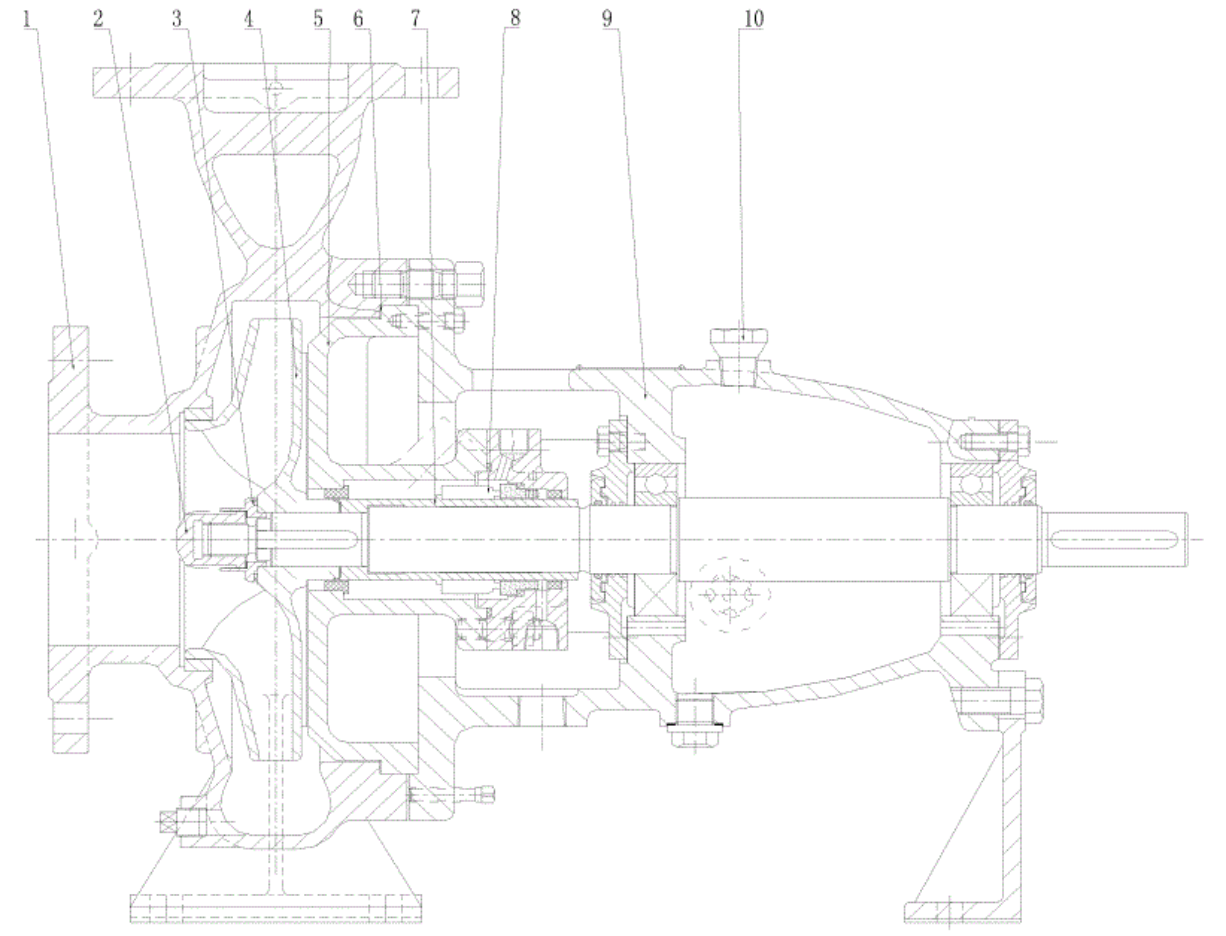

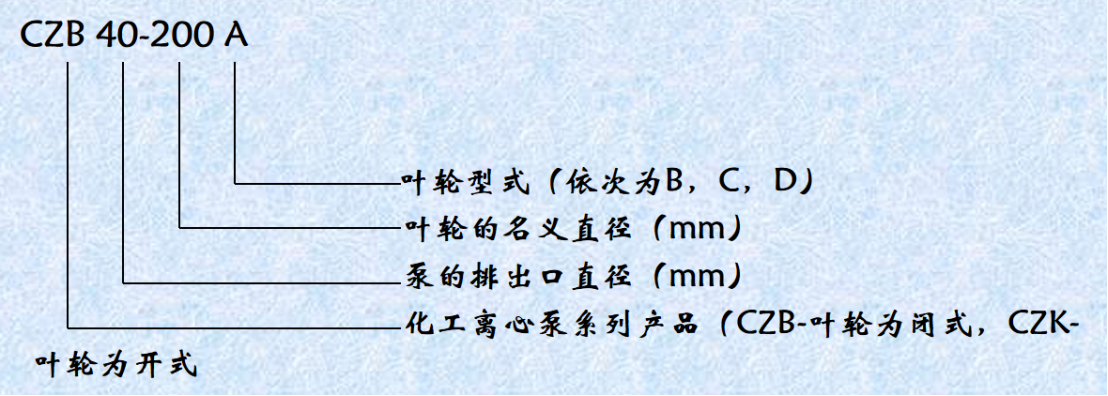

CZ标准化工泵结构图

1、泵体 2、*叶轮螺母 3、*止动卡盘 4、叶轮 5、泵盖 6、*密封垫

7、*轴套 8、密封部件 9、轴承架部件 10、放气塞 11、(带“*”零件为易损件)

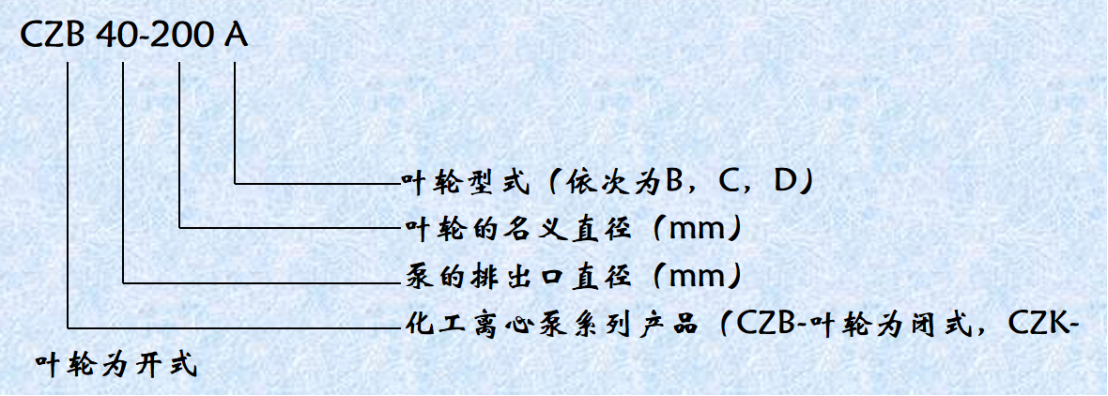

CZ标准化工泵型号意义

CZ标准化工泵结构说明

CZ化工泵是卧式后开门结构,泵头与电机采用联轴器连接,安装在底板上,叶轮为后开式,三只轴承,轴封采用外装式机械密封,设有冷却装置,轴承体的油位用油镜观察;结构紧凑合理。该泵在泵体上铸有支脚,可承受来自管路的荷载并直接传给基础,这样泵转子不会因泵承受荷载而产生弯曲,从而保证了承载和机械密封具有良好的使用寿命。维修时不需将与泵体相连的管路打开,只要打开托架与泵体的螺栓, 将两者分开就可维修叶轮和机械密封,简易方便。

泵的旋转方向:从电机端朝泵看,顺时针方向旋转。

CZ化工泵适用的行业与介质

CZ泵适用于氯碱、纯碱工业;医学、化肥、农药;石油化工、化纤、造纸工业;染料工业;环保工程及水处理系统。主要有:

(1) 各种温度和浓度的硫酸、硝酸、盐酸和磷酸等无机酸和有机酸。

(2) 各种温度和浓度下的氢氧化钠和碳酸钠等碱性溶液。

(3) 各种盐溶液。

(4) 各种液态石油化工产品、有机化合物,以及其它有腐蚀性的原料和产品。

目前我公司的耐腐蚀材料,能满足上述各种介质的要求。订货时,请用户提供所要输送介质的详细情况。

CZ标准化工泵性能参数表

| 型号 Model | 叶轮形式 Impeller?type | 泵额定转速 n=2900r/min speed | |||||||||||

| 流量 Q M3/h Capacity | 扬程H Head m | 汽蚀余量NPSH m | 效率 Efficencyη % | 比重 Density 1 | 比重 Density 1.35 | 比重 Density 1.84 | |||||||

| 电机功率及型号? motor power or model | |||||||||||||

| kw | kw | kw | |||||||||||

| CZ32-160 | A | 20 | 36 | 3.1 | 62 | 4 | Y112M-2 | 5.5 | Y132S1-2 | 7.5 | Y132S2-2 | ||

| B | 18 | 32 | 4 | Y112M-2 | 5.5 | Y132S1-2 | 7.5 | Y132S2-2 | |||||

| C | 17 | 28 | 3 | Y100L-2 | 4 | Y112M-2 | 5.5 | Y132S1-2 | |||||

| D | 15 | 20 | 2.2 | Y90L-2 | 3 | Y100L-2 | 4 | Y112M-2 | |||||

| E | 13 | 14 | |||||||||||

| CZ32-200 | A | 20 | 50 | 2.7 | 51 | 7.5 | Y132S2-2 | 11 | Y160M1-2 | 15 | Y160M2-2 | ||

| B | 18 | 48 | 11 | Y160M1-2 | |||||||||

| C | 16 | 40 | 5.5 | Y132S1-2 | 7.5 | Y132S2-2 | |||||||

| D | 15 | 30 | 4 | Y112M-2 | 5.5 | Y132S1-2 | 7.5 | Y132S2-2 | |||||

| CZ32-250 | A | 20 | 85 | 2.1 | 40 | 15 | Y160M2-2 | 18.5 | Y160L-2 | 30 | Y200L1-2 | ||

| B | 20 | 75 | |||||||||||

| C | 18 | 65 | 11 | Y160M1-2 | 15 | Y160M2-2 | 18.5 | Y160L-2 | |||||

| D | 15 | 50 | 7.5 | Y132S2-2 | 11 | Y160M1-2 | 15 | Y160M2-2 | |||||

| CZ40-160 | A | 30 | 34 | 1.5 | 63 | 7.5 | Y132S2-2 | 11 | Y160M1-2 | 15 | Y160M2-2 | ||

| B | 28 | 30 | 5.5 | Y132S1-2 | 7.5 | Y132S2-2 | 11 | Y160M1-2 | |||||

| C | 16 | 26 | 5.5 | Y132S1-2 | 7.5 | Y132S2-2 | |||||||

| D | 14 | 18 | 3 | Y100L-2 | 5.5 | Y132S1-2 | |||||||

| CZ40-200 | A | 34 | 50 | 2.4 | 60 | 11 | Y160M1-2 | 15 | Y160M2-2 | 18.5 | Y160L-2 | ||

| B | 30 | 48 | 7.5 | Y132S2-2 | 11 | Y160M1-2 | 15 | Y160M2-2 | |||||

| C | 26 | 38 | 5.5 | Y132S1-2 | 7.5 | Y132S2-2 | 11 | Y160M1-2 | |||||

| D | 22 | 30 | |||||||||||

| 1 | |||||||||||||

| CZ40-250 | A | 36 | 85 | 6 | 50 | 22 | Y180M-2 | 30 | Y200L1-2 | 45 | Y225M-2 | ||

| B | 34 | 80 | 18.5 | Y160L-2 | 22 | Y180M-2 | 37 | Y200L2-2 | |||||

| C | 30 | 65 | 15 | Y160M2-2 | 18.5 | Y160L-2 | 30 | Y200L1-2 | |||||

| D | 26 | 50 | 11 | Y160M1-2 | 15 | Y160M2-2 | 18.5 | Y160L-2 | |||||

| CZ40-315 | A | 46 | 140 | 4 | 50 | 45 | Y225M-2 | 55 | Y250M-2 | 75 | Y280S-2 | ||

| B | 44 | 130 | 37 | Y200L2-2 | 45 | Y225M-2 | 75 | Y280S-4 | |||||

| C | 40 | 100 | 30 | Y200L1-2 | 37 | Y200L2-2 | 55 | Y250M-2 | |||||

| D | 34 | 80 | 30 | Y200L1-2 | 37 | Y200L2-2 | |||||||

| CZ50-160 | A | 55 | 34 | 2.9 | 73 | 11 | Y160M1-2 | 11 | Y160M1-2 | 15 | Y160L2-2 | ||

| B | 50 | 30 | 7.5 | Y132S2-2 | |||||||||

| C | 46 | 26 | 5.5 | Y132S1-2 | 7.5 | Y132S2-2 | 11 | Y160M1-2 | |||||

| D | 40 | 18 | 5.5 | Y132S1-2 | 7.5 | Y132S2-2 | |||||||

| CZ50-200 | A | 65 | 56 | 4 | 72 | 18.5 | Y160L-2 | 22 | Y180M-2 | 45 | Y225S-2 | ||

| B | 65 | 50 | 15 | Y160M2-2 | 18.5 | Y160L-2 | 37 | Y200L2-2 | |||||

| C | 50 | 40 | 11 | Y160M1-2 | 15 | Y160M2-2 | 18.5 | Y160L-2 | |||||

| D | 40 | 32 | 7.5 | Y132S2-2 | 11 | Y160M1-2 | 15 | Y160M2-2 | |||||

| CZ50-250 | A | 65 | 85 | 3 | 64 | 30 | Y200L1-2 | 37 | Y200L2-2 | 45 | Y225M-2 | ||

| B | 60 | 80 | 45 | Y225M-2 | |||||||||

| C | 55 | 65 | 22 | Y160M-2 | 30 | Y200L1-2 | 37 | Y200L2-2 | |||||

| D | 45 | 50 | 15 | Y160M2-2 | 15 | Y160M2-2 | 22 | Y180M-2 | |||||

| CZ50-315 | A | 80 | 140 | 5 | 60 | 75 | Y280S-2 | 90 | Y280M-2 | 110 | Y315S-2 | ||

| B | 75 | 135 | 55 | Y250M-2 | 75 | Y280S-2 | 110 | Y315S-2 | |||||

| C | 70 | 110 | 45 | Y225M-2 | 90 | Y280M-2 | |||||||

| D | 65 | 85 | 37 | Y200L2-2 | 45 | Y225M-2 | 75 | Y280S-2 | |||||

CZ标准化工泵性能参数表2

| 型号 Model | 叶轮形式 Impellertype | 泵额定转速?n=2900r/min?speed | |||||||||||

| 流量 Q M3/h Capacity | 扬程 H m Head | 汽蚀余量 NPSH m | 效率 η Efficency % | 比重 1 Density | 比重 1.35 Density | 比重 1.84 Density | |||||||

| 电机功率及型号? motor power or model | |||||||||||||

| kw | kw | kw | |||||||||||

| CZ65-160 | A | 100 | 32 | 3 | 74 | 15 | Y160M2-2 | 18.5 | Y160L-2 | 30 | Y200L1-2 | ||

| B | 90 | 32 | 22 | Y180M-2 | |||||||||

| C | 90 | 24 | 11 | Y160M1-2 | 15 | Y160M2-2 | 18.5 | Y160L-2 | |||||

| D | 80 | 14 | 5.5 | Y132S1-2 | 7.5 | Y132S2-2 | 11 | Y160M1-2 | |||||

| A | 100 | 54 | 3.2 | 73 | 22 | Y180M2-2 | 30 | Y200L1-2 | 37 | Y200L2-2 | |||

| B | 90 | 50 | |||||||||||

| C | 90 | 40 | 18.5 | Y160L-2 | 22 | Y180M-2 | 30 | Y200L1-2 | |||||

| D | 70 | 30 | 11 | Y160M1-2 | 15 | Y160M2-2 | 18.5 | Y160L-2 | |||||

| CZ65-250 | A | 115 | 85 | 3.4 | 71 | 45 | Y225M-2 | 55 | Y250M-2 | ||||

| B | 115 | 75 | |||||||||||

| C | 100 | 65 | 37 | Y200L2-2 | 45 | Y225M-2 | 55 | Y250M-2 | |||||

| D | 80 | 50 | 30 | Y200L1-2 | 30 | Y200L1-2 | 37 | Y200L2-2 | |||||

| CZ65-315 | A | 135 | 135 | 5.5 | 66 | 90 | Y280M-2 | 110 | Y315S-2 | 160 | Y315M2-2 | ||

| B | 130 | 125 | |||||||||||

| C | 115 | 115 | 75 | Y280S-2 | 90 | Y280M-2 | 132 | Y315M1-2 | |||||

| D | 110 | 110 | 55 | Y250M-2 | 75 | Y280S-2 | 110 | Y315S-2 | |||||

| E | 90 | 85 | 45 | Y225M-2 | 55 | Y250M-2 | 75 | Y280S-2 | |||||

| F | 75 | 70 | 30 | Y200L1-2 | 45 | Y225M-2 | 55 | Y250M-2 | |||||

| CZ80-160 | A | 170 | 30 | 4.2 | 76 | 22 | Y180M-2 | 30 | Y200L1-2 | 37 | Y200L2-2 | ||

| B | 160 | 26 | 18.5 | Y160L-2 | 22 | Y180M-2 | |||||||

| C | 150 | 22 | 15 | Y160M2-2 | 18.5 | Y160L-2 | 30 | Y200L1-2 | |||||

| D | 130 | 16 | 11 | Y160M1-2 | 15 | Y160M2-2 | 18.5 | Y160L-2 | |||||

| CZ80-200 | A | 150 | 50 | 3.8 | 79 | 37 | Y200L2-2 | 45 | Y225M-2 | 55 | Y250M-2 | ||

| B | 140 | 46 | 30 | Y200L1-2 | 37 | Y200L2-2 | 55 | Y250M-2 | |||||

| C | 130 | 38 | 22 | Y180M-2 | 30 | Y200L1-2 | 37 | Y200L2-2 | |||||

| D | 110 | 26 | 15 | Y160M2-2 | 18.5 | Y160L-2 | 30 | Y200L1-2 | |||||

| CZ80-250 | A | 190 | 80 | 5 | 80 | 75 | Y280S-2 | 90 | Y280M-2 | 110 | Y315S-2 | ||

| B | 180 | 75 | 55 | Y250M-2 | 75 | Y280S-2 | 110 | Y315S-2 | |||||

| C | 170 | 70 | 45 | Y225M-2 | 75 | Y280S-2 | 90 | Y280M-2 | |||||

| D | 150 | 55 | 37 | Y200L2-2 | 55 | Y250M-2 | 75 | Y280S-2 | |||||

| E | 130 | 47 | 30 | Y200L1-2 | 37 | Y200L2-2 | 55 | Y250M-2 | |||||

| CZ80-315 | A | 200 | 130 | 5.5 | 76.5 | 110 | Y315S2-2 | 160 | Y315M2-2 | ||||

| B | 180 | 125 | 132 | Y315M1-2 | |||||||||

| C | 160 | 100 | 75 | Y280S-2 | 90 | Y280M-2 | 132 | Y315M1-2 | |||||

| D | 150 | 75 | 55 | Y250M-2 | 75 | Y280S-2 | 90 | Y280M-2 | |||||

| CZ100-200 | A | 220 | 45 | 4 | 81 | 45 | Y225M-2 | 55 | Y250M-2 | 75 | Y280S-2 | ||

| B | 200 | 40 | 30 | Y200L2-2 | 45 | Y225M-2 | 55 | Y250M-2 | |||||

| C | 180 | 30 | 22 | Y180M-2 | 30 | Y200L1-2 | 45 | Y225M-2 | |||||

| D | 150 | 25 | 37 | Y200L1-2 | |||||||||

| CZ100-250 | A | 280 | 75 | 4.9 | 81.5 | 90 | Y280M-2 | 110 | Y315S-2 | 160 | Y315M2-2 | ||

| B | 250 | 70 | 75 | Y280S-2 | 132 | Y315M1-2 | |||||||

| C | 230 | 55 | 55 | Y250M-2 | 75 | Y280S-2 | 110 | Y315S-2 | |||||

| D | 200 | 40 | 37 | Y200L2-2 | 55 | Y250M-2 | 75 | Y280S-2 | |||||

| CZ100-315 | A | 270 | 135 | 5.5 | 75.5 | 160 | Y315M2-2 | ||||||

| B | 250 | 130 | 132 | Y315M1-2 | |||||||||

| C | 230 | 100 | 110 | Y315S-2 | 132 | Y315M1-2 | |||||||

| D | 200 | 85 | 75 | Y280S-2 | 110 | Y315S-2 | 132 | Y315M1-2 | |||||

CZ标准化工泵性能参数表3

| 型号 Model | 叶轮形式 Impeller type | 泵额定转速?n=14500r/min speed | |||||||||

| 流量 Q M3/h Capacity | 扬程 H m Head | 汽蚀余量 NPSH m | 效率 η Efficency % | 比重 1 Density | 比重 1.35 Density | 比重 1.35 Density | |||||

| 电机功率及型号? motor power or model | |||||||||||

| kw | kw | kw | |||||||||

| CZ32-160 | A | 11 | 9 | 1.5 | 49 | 1.1 | Y90S-4 | 1.1 | Y90S-4 | 1.5 | Y90L-4 |

| B | 10 | 8 | |||||||||

| C | 9 | 7 | 1.1 | Y90S-4 | |||||||

| D | 6 | 5 | |||||||||

| E | 6 | 3 | |||||||||

| CZ32-200 | A | 10 | 13 | 1 | 47 | 1.5 | Y90L-4 | 1.5 | Y90L-4 | 2.2 | Y100L1-4 |

| B | 9 | 12 | 1.5 | Y90L-4 | |||||||

| C | 8 | 10 | |||||||||

| D | 8 | 8 | |||||||||

| CZ32-250 | A | 11 | 20 | 0.9 | 37 | 2.2 | Y100L1-4 | 3 | Y100L2-4 | 4 | Y112M-4 |

| B | 10 | 19 | |||||||||

| C | 9 | 15 | 2.2 | Y100L1-4 | 3 | Y100L2-4 | |||||

| D | 8 | 11 | 2.2 | Y100L1-4 | |||||||

| CZ40-160 | A | 15 | 8 | 0.5 | 60 | 1.1 | Y90S-4 | 1.1 | Y90S-4 | 1.5 | Y90L-4 |

| B | 15 | 7 | |||||||||

| C | 14 | 6 | 1.1 | Y90S-4 | |||||||

| D | 12 | 4 | |||||||||

| CZ40-200 | A | 16 | 13 | 1.1 | 57 | 1.5 | Y90L-4 | 1.5 | Y90L-4 | 2.2 | Y100L1-4 |

| B | 15 | 12 | 1.1 | Y90S-4 | |||||||

| C | 14 | 9 | 1.1 | Y90S-4 | 1.5 | Y90L-4 | |||||

| D | 12 | 7 | 1.1 | Y90S-4 | |||||||

| 1 | |||||||||||

| CZ40-250 | A | 20 | 21 | 2.5 | 48 | 4 | Y112M-4 | 5.5 | Y132S-4 | 5.5 | Y132S-4 |

| B | 18 | 20 | 3 | Y100L2-4 | 4 | Y112M-4 | |||||

| C | 16 | 15 | 2.2 | Y100L1-4 | 3 | Y100L2-4 | 4 | Y112M-4 | |||

| D | 13 | 12 | 2.2 | Y100L1-4 | 2.2 | Y100L1- | |||||

| CZ40-315 | A | 22 | 36 | 1 | 45 | 11 | Y160M-4 | 11 | Y160M-4 | 11 | Y160M-4 |

| B | 22 | 32 | 5.5 | Y132S-4 | |||||||

| C | 20 | 24 | 4 | Y112M-4 | 5.5 | Y132S-4 | |||||

| D | 18 | 18 | 4 | Y112M-4 | 5.5 | Y132S-4 | |||||

| CZ50-160 | A | 30 | 8 | 1.6 | 70 | 1.5 | Y90L-4 | 2.2 | Y100L1-4 | 3 | Y100L2-4 |

| B | 26 | 7 | 1.1 | Y90S-4 | 1.5 | Y90L-4 | 2.2 | Y100L1-4 | |||

| C | 24 | 6 | 1.1 | Y90S-4 | 1.5 | Y90L-4 | |||||

| D | 20 | 4 | 1.1 | Y90S-4 | |||||||

| CZ50-200 | A | 34 | 14 | 1.5 | 70 | 3 | Y100L2-4 | 4 | Y100L2-4 | 5.5 | Y132S-4 |

| B | 32 | 12 | 2.2 | Y100L1-4 | 3 | Y100L2-4 | 4 | Y112M-4 | |||

| C | 30 | 10 | 1.5 | Y90L-4 | 2.2 | Y100L1-4 | 3 | Y100L2-4 | |||

| D | 24 | 7 | 1.5 | Y90L-4 | 2.2 | Y100L1-4 | |||||

| CZ50-250 | A | 34 | 21 | 1.1 | 59 | 5.5 | Y132S-4 | 5.5 | Y132S-4 | 11 | Y160M-4 |

| B | 30 | 20 | 4 | Y112M-4 | |||||||

| C | 26 | 16 | 3 | Y100L2-4 | 4 | Y112M-4 | 5.5 | Y132S-4 | |||

| D | 24 | 12 | 2.2 | Y100L1-4 | 3 | Y100L2-4 | 4 | Y112M-4 | |||

CZ标准化工泵性能参数表4

| 型号 Model | 叶轮形式 Impeller type | 泵额定转速 n=14500r/min speed | |||||||||

| 流量 Q M3/h Capacity | 扬程 H m Head | 汽蚀余量 NPSH m | 效率 η Efficency % | 比重 1 Density | 比重 1.35 Density | 比重 1.35 Density | |||||

| 电机功率及型号? motor power or model | |||||||||||

| kw | kw | kw | |||||||||

| CZ50-315 | A | 42 | 36 | 1.8 | 58 | 11 | Y160M-4 | 11 | Y160M-4 | 15 | Y160L-4 |

| B | 42 | 32 | |||||||||

| C | 40 | 26 | 11 | Y160M-4 | |||||||

| D | 36 | 20 | |||||||||

| CZ65-160 | A | 50 | 8 | 1.5 | 68 | 2.2 | Y100L1-4 | 3 | Y100L2-4 | 4 | Y112M-4 |

| B | 48 | 7 | |||||||||

| C | 46 | 6 | 2.2 | Y100L1-4 | 3 | Y100L2-4 | |||||

| D | 38 | 4 | |||||||||

| A | 50 | 13 | 1 | 73 | 4 | Y112M-4 | 4 | Y112M-4 | 5.5 | Y132S-4 | |

| B | 46 | 12 | 3 | Y100L2-4 | |||||||

| C | 42 | 10 | 3 | Y100L2-4 | 4 | Y112M-4 | |||||

| D | 36 | 7 | 2.2 | Y100L1-4 | 2.2 | Y100L1-4 | 3 | Y100L2-4 | |||

| CZ65-250 | A | 54 | 21 | 0.9 | 67 | 11 | Y160M-4 | 11 | Y160M-4 | 11 | Y160M-4 |

| B | 50 | 20 | 5.5 | Y132S-4 | |||||||

| C | 46 | 16 | 4 | Y112M-4 | 5.5 | Y132S-4 | |||||

| D | 40 | 10 | 4 | Y112M-4 | 5.5 | Y132S-4 | |||||

| CZ65-315 | A | 64 | 32 | 1.3 | 62 | 11 | Y160M-4 | 15 | Y160L-4 | 18.5 | Y180M-4 |

| B | 61 | 30 | |||||||||

| C | 56 | 28 | 11 | Y160M-4 | 15 | Y160L-4 | |||||

| D | 54 | 24 | |||||||||

| E | 50 | 20 | 5.5 | Y132S-4 | 11 | Y160M-4 | |||||

| F | 52 | 16 | 5.5 | Y132S-4 | |||||||

| CZ80-160 | A | 75 | 8 | 2.2 | 70 | 3 | Y100L2-4 | 4 | Y112M-4 | 5.5 | Y132S-4 |

| B | 70 | 7 | 3 | Y100L2-4 | 4 | Y112m-4 | |||||

| C | 70 | 5 | 2.2 | Y100L1-4 | |||||||

| D | 65 | 4 | 2.2 | Y100L1-4 | 2.2 | Y100L1-4 | |||||

| CZ80-200 | A | 80 | 12 | 1.9 | 73 | 5.5 | Y132S-4 | 11 | Y160M-4 | 11 | Y160M-4 |

| B | 75 | 11 | 4 | Y112M-4 | 5.5 | Y132S-4 | |||||

| C | 65 | 9 | 3 | Y100L2-4 | 4 | Y112M-4 | 5.5 | Y132S-4 | |||

| D | 60 | 6 | 3 | Y100L2-4 | 4 | Y112M-4 | |||||

| CZ80-250 | A | 90 | 20 | 1.3 | 78 | 11 | Y160M-4 | 11 | Y160M-4 | 15 | Y160L-4 |

| B | 90 | 19 | |||||||||

| C | 85 | 17 | |||||||||

| D | 75 | 14 | 5.5 | Y132S-4 | 11 | Y160M-4 | |||||

| E | 70 | 11 | 5.5 | Y132S-4 | |||||||

| CZ80-315 | A | 100 | 32 | 1.3 | 72.5 | 15 | Y160L-4 | 18.5 | Y180M-4 | 30 | Y200L-4 |

| B | 95 | 30 | |||||||||

| C | 85 | 24 | 15 | Y160L-4 | 18.5 | Y180M-4 | |||||

| D | 70 | 18 | 15 | Y160L-4 | |||||||

| CZ80-400 | A | 105 | 52 | 1.2 | 63 | 30 | Y200L-4 | 37 | Y225S-4 | 55 | Y250M-4 |

| B | 100 | 50 | 55 | Y250M-4 | |||||||

| C | 90 | 44 | 30 | Y200L-4 | 45 | Y225M-4 | |||||

| D | 80 | 38 | 18.5 | Y180M-4 | 37 | Y225S-4 | |||||

| E | 75 | 30 | 18.5 | Y180M-4 | 30 | Y200L-4 | |||||

CZ标准化工泵性能参数表5

| 型号 Model | 叶轮形式 Impeller type | 泵 额 定 转 速?n=14500r/min?speed | |||||||||

| 流量 Q M3/h Capacity | 扬程 H m Head | 汽蚀余量 NPSH m | 效率η Efficency % | 比重 1 Density | 比重 1.35 Density | 比重 1.35 Density | |||||

| 电机功率及型号? motor power or model | |||||||||||

| kw | - | kw | - | kw | - | ||||||

| CZ100-200 | A | 115 | 11 | 1.2 | 80 | 5.5 | Y132S-4 | 11 | Y160M-4 | 11 | Y160M-4 |

| B | 100 | 10 | |||||||||

| C | 90 | 8 | 5.5 | Y132S-4 | 5.5 | Y132S-4 | |||||

| D | 80 | 6 | |||||||||

| CZ100-250 | A | 130 | 20 | 1.2 | 75.5 | 15 | Y160L-4 | 30 | Y200L-4 | 30 | Y200L-4 |

| B | 130 | 18 | 11 | Y160M-4 | 15 | Y160L-4 | |||||

| C | 120 | 14 | 11 | Y160M-4 | 15 | Y160L-4 | |||||

| D | 100 | 10 | 11 | Y160M-4 | |||||||

| CZ100-315 | A | 132 | 32 | 1.5 | 72 | 30 | Y200L-4 | 30 | Y200L-4 | 37 | Y225S-4 |

| B | 120 | 30 | 18.5 | Y180M-4 | 30 | Y200L-4 | |||||

| C | 100 | 26 | 15 | Y160L-4 | 15 | Y160L-4 | |||||

| D | 90 | 21 | 18.5 | Y180M-4 | |||||||

| CZ10-400 | A | 150 | 50 | 2 | 70 | 45 | Y225M-4 | 45 | Y225M-4 | 75 | Y280S-4 |

| B | 140 | 48 | 30 | Y200L-4 | 55 | Y250M-4 | |||||

| C | 120 | 40 | 30 | Y200L-4 | 45 | Y225M-4 | |||||

| D | 100 | 30 | 18.5 | Y180M-4 | 30 | Y200L-4 | |||||

| CZ125-250 | A | 200 | 20 | 2.2 | 84 | 18.5 | Y180M-4 | 22 | Y180L-4 | 30 | Y200L-4 |

| B | 200 | 18 | 15 | Y160L-4 | 18.5 | Y180M-4 | 33 | Y200L-4 | |||

| C | 190 | 14 | 11 | Y160M-4 | 15 | Y160M-4 | 22 | Y180L-4 | |||

| D | 160 | 10 | 11 | Y160M-4 | 15 | Y160L-4 | |||||

| CZ125-315 | A | 200 | 30 | 2 | 79 | 30 | Y200L-4 | 37 | Y225S-4 | 45 | Y225M-4 |

| B | 180 | 30 | 30 | Y200L-4 | 37 | Y225S-4 | |||||

| C | 170 | 24 | 18.5 | Y180M-4 | 30 | Y200L-4 | |||||

| D | 100 | 18 | 15 | Y160L-4 | 18.5 | Y180M-4 | |||||

| CZ125-400 | A | 220 | 50 | 2.2 | 74.5 | 55 | Y250M-4 | 75 | Y280S-4 | 90 | Y280M-4 |

| B | 200 | 48 | 45 | Y225M-4 | 75 | Y280S-4 | 75 | Y280S-4 | |||

| C | 180 | 46 | 37 | Y225S-4 | 55 | Y250M-4 | 75 | Y280S-4 | |||

| D | 170 | 42 | 30 | Y200L-4 | 45 | Y225M-4 | 55 | Y250M-4 | |||

| E | 150 | 36 | 30 | Y200L-4 | 45 | Y225M-4 | |||||

| F | 150 | 30 | 37 | Y225S-4 | |||||||

| CZ150-250 | A | 320 | 17 | 3.5 | 83 | 22 | Y180L-4 | 30 | Y200L-4 | 37 | Y225S-4 |

| B | 300 | 15 | 18.5 | Y180M-4 | |||||||

| C | 280 | 13 | |||||||||

| D | 260 | 12 | 15 | Y160L-4 | 18.5 | Y180M-4 | 30 | Y220L-4 | |||

| E | 240 | 11 | 11 | Y160M-4 | 15 | Y160L-4 | 22 | Y180L-4 | |||

| CZ150-315 | A | 380 | 30 | 3 | 82.5 | 45 | Y225M-4 | 75 | Y280S-4 | - | - |

| B | 340 | 26 | 37 | Y225S-4 | 45 | Y225M-4 | - | - | |||

| C | 320 | 20 | 30 | Y200L-4 | 37 | Y225S-4 | 55 | Y250M-4 | |||

| D | 300 | 17 | 22 | Y180L-4 | 30 | Y200L-4 | 37 | Y225S-4 | |||

| CZ150-400 | A | 400 | 48 | 4.3 | 80 | 75 | Y280S-4 | 110 | Y315S-4 | - | - |

| B | 340 | 40 | 55 | Y250M-4 | 75 | Y280S-4 | - | - | |||

| C | 300 | 34 | 45 | Y225M-4 | 90 | Y280S-4 | |||||

| D | 260 | 28 | 37 | Y225S-4 | 45 | Y225M-4 | 75 | Y280M-4 | |||

CZ标准化工泵性能参数表6

| 型号 Model | 叶轮形式 Impeller type | 泵额定转速 n=14500r/min speed | |||||||||

| 流量 Q M3/h Capacity | 扬程 H m Head | 汽蚀余量 NPSH m | 效率η Efficency % | 比重 1 Density | 比重 1.35 Density | 比重 1.35 Density | |||||

| 电机功率及型号? motor power or model | |||||||||||

| kw | - | kw | - | kw | - | ||||||

| CZ150-500 | A | 420 | 80 | 2.5 | 78 | 132 | Y315M1-4 | - | - | - | - |

| B | 400 | 70 | 110 | Y315S-4 | 160 | Y315M2-4 | - | - | |||

| C | 360 | 65 | 132 | Y315M1-4 | - | - | |||||

| D | 340 | 50 | 75 | Y280S-4 | 110 | Y315S-4 | 132 | Y315M1-4 | |||

| E | 300 | 45 | 55 | Y225M-4 | 75 | Y280S-4 | 110 | Y315S-4 | |||

| - | - | - | - | - | - | - | - | - | - | - | |

| CZ200-250 | A | 600 | 12 | 3.5 | 85 | 30 | Y200L-4 | 37 | Y225S-4 | 55 | Y250M-4 |

| B | 540 | 11 | 22 | Y180L-4 | 30 | Y200L-4 | 45 | Y225M-4 | |||

| C | 500 | 10 | 37 | Y225S-4 | |||||||

| CZ200-315 | A | 650 | 24 | 4 | 83.5 | 55 | Y250M-4 | 75 | Y280S-4 | 100 | Y315S-4 |

| B | 600 | 20 | 90 | Y280M-4 | |||||||

| C | 550 | 16 | 37 | Y225S-4 | 45 | Y225M-4 | 75 | Y280S-4 | |||

| D | 500 | 13 | 30 | Y200L-4 | 37 | Y225S-4 | 55 | Y250M-4 | |||

| CZ200-400 | A | 650 | 52 | 3.5 | 84 | 132 | Y315M1-4 | - | - | - | - |

| B | 550 | 45 | 90 | Y280M-4 | 132 | Y315M1-4 | - | - | |||

| C | 500 | 40 | 75 | Y280S-4 | 110 | Y315S-4 | 160 | Y315M2-4 | |||

| D | 450 | 30 | 55 | Y250M-4 | 75 | Y280S-4 | 110 | Y315S-4 | |||

| CZ200-500 | A | 700 | 75 | 3 | 81.5 | - | - | - | - | - | - |

| B | 650 | 65 | 160 | Y315M2-4 | - | - | - | - | |||

| C | 550 | 55 | 110 | Y250M-4 | 160 | Y315M2-4 | - | - | |||

| D | 450 | 40 | 75 | Y280S-4 | 110 | Y315S-4 | 132 | Y315M1-4 | |||

| CZ250-315 | A | 950 | 22 | 5 | 86 | 75 | Y280S-4 | 110 | Y315S-4 | 160 | Y315M2-4 |

| B | 900 | 20 | 90 | Y280M-4 | 132 | Y315M1-4 | |||||

| C | 800 | 16 | 55 | Y250M-4 | 75 | Y280S-4 | 110 | Y315S-4 | |||

| D | - | - | - | - | - | - | - | - | |||

| CZ250-400 | A | 1000 | 44 | 6 | 83 | 160 | Y315M2-4 | - | - | - | - |

| B | 900 | 38 | 132 | Y315M1-4 | - | - | - | - | |||

| C | 850 | 30 | 110 | Y315S-4 | 160 | Y315M2-4 | - | - | |||

| D | 800 | 24 | 90 | Y280M-4 | 110 | Y315S-4 | 160 | Y315M2-4 | |||

| CZ250-500 | A | 1200 | 80 | 6 | 85 | - | - | - | - | - | - |

| B | 1100 | 70 | - | - | - | - | - | - | |||

| C | 1000 | 55 | - | - | - | - | - | - | |||

| D | 850 | 45 | 160 | Y315M2-4 | - | - | - | - | |||

| CZ300-400 | A | 1500 | 40 | 6 | 87 | - | - | - | - | - | - |

| B | 1400 | 30 | 160 | Y315M2-4 | - | - | - | - | |||

| C | 1300 | 25 | 132 | Y315M1-4 | - | - | - | - | |||

| D | 1300 | 20 | 110 | Y315S-4 | 160 | Y315M2-4 | - | - | |||

| CZ300-500 | A | 1700 | 70 | 6 | 83.5 | - | - | - | - | - | - |

| B | 1500 | 60 | - | - | - | - | - | - | |||

| C | 1300 | 50 | - | - | - | - | - | - | |||

| D | 1100 | 40 | - | - | - | - | - | - | |||

CZ标准化工泵型号说明

CZ标准化工泵型号概述

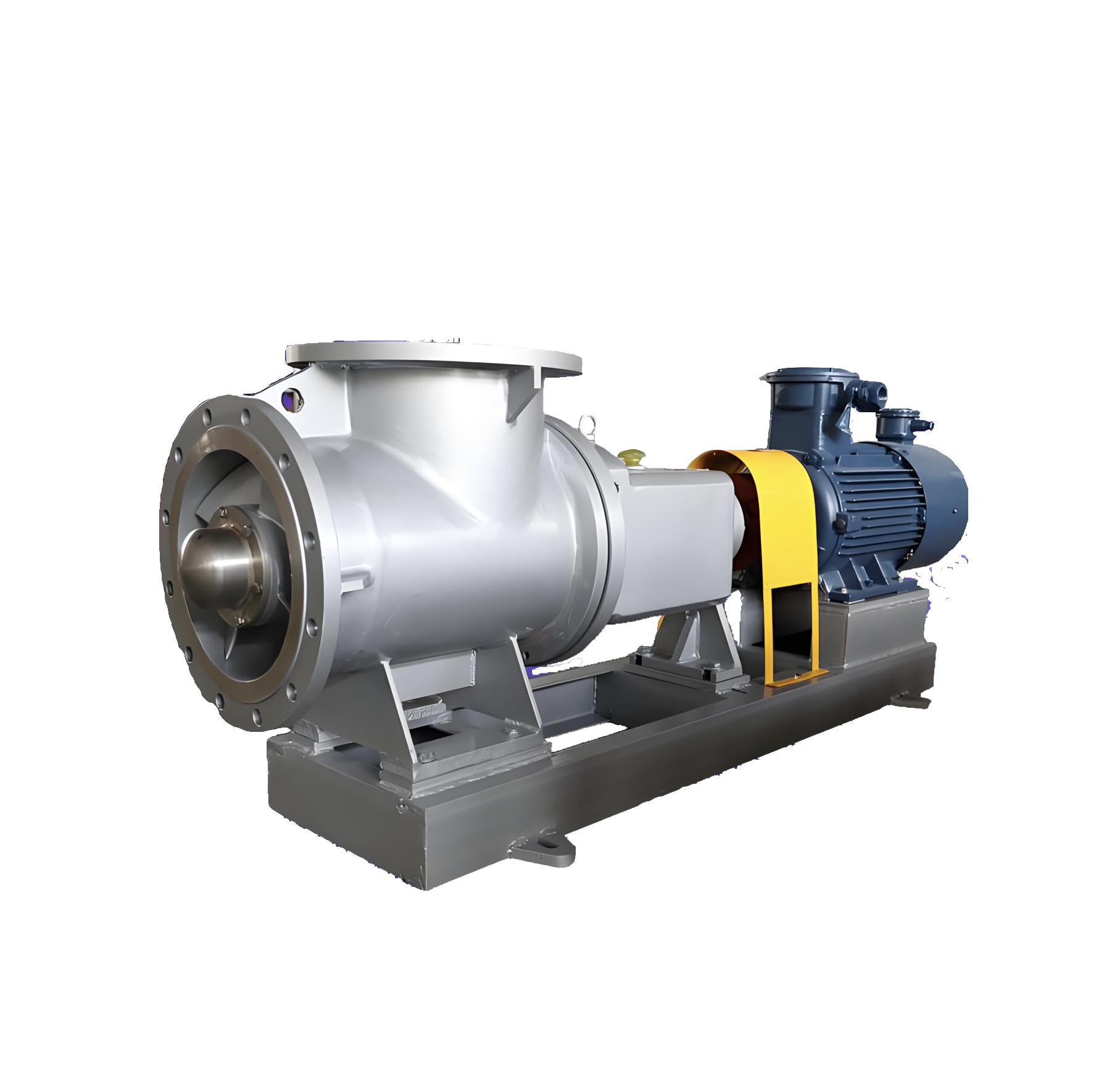

CZB、CZK型系列化工离心泵为卧式单级单吸式离心泵,其性能指标符合GB13007-91;GB13006-91标准,制造标准依据GB5656-1994《离心泵技术条件》Ⅱ类。

用于输送低温或高温液体,中性或有腐蚀性液体,洁净或含有固体颗粒的液体,可用于化学和石油化学工业、炼油厂、造纸、食品等工业。

输送介质的温度一般为-20~105℃,必要时采用适当的措施,可以输送更高温度的介质。

泵的最高工作压力按2.5Mpa设计。

根据被输送介质对泵的腐蚀情况,用户可选用相应的过流零部件材质。主要材质如表一

表一 触液部位材料代号

| 材料符号 | ZG1Cr18Ni9Ti | ZG0Cr18Ni9 | ZG0Cr17Ni14Mo2 | ZG0Cr18Ni12Mo2Ti | ZG1Cr13 |

注:根据用户需要,我公司还可生产其它材质产品

CZ标准化工泵CZB和CZK型号的结构说明

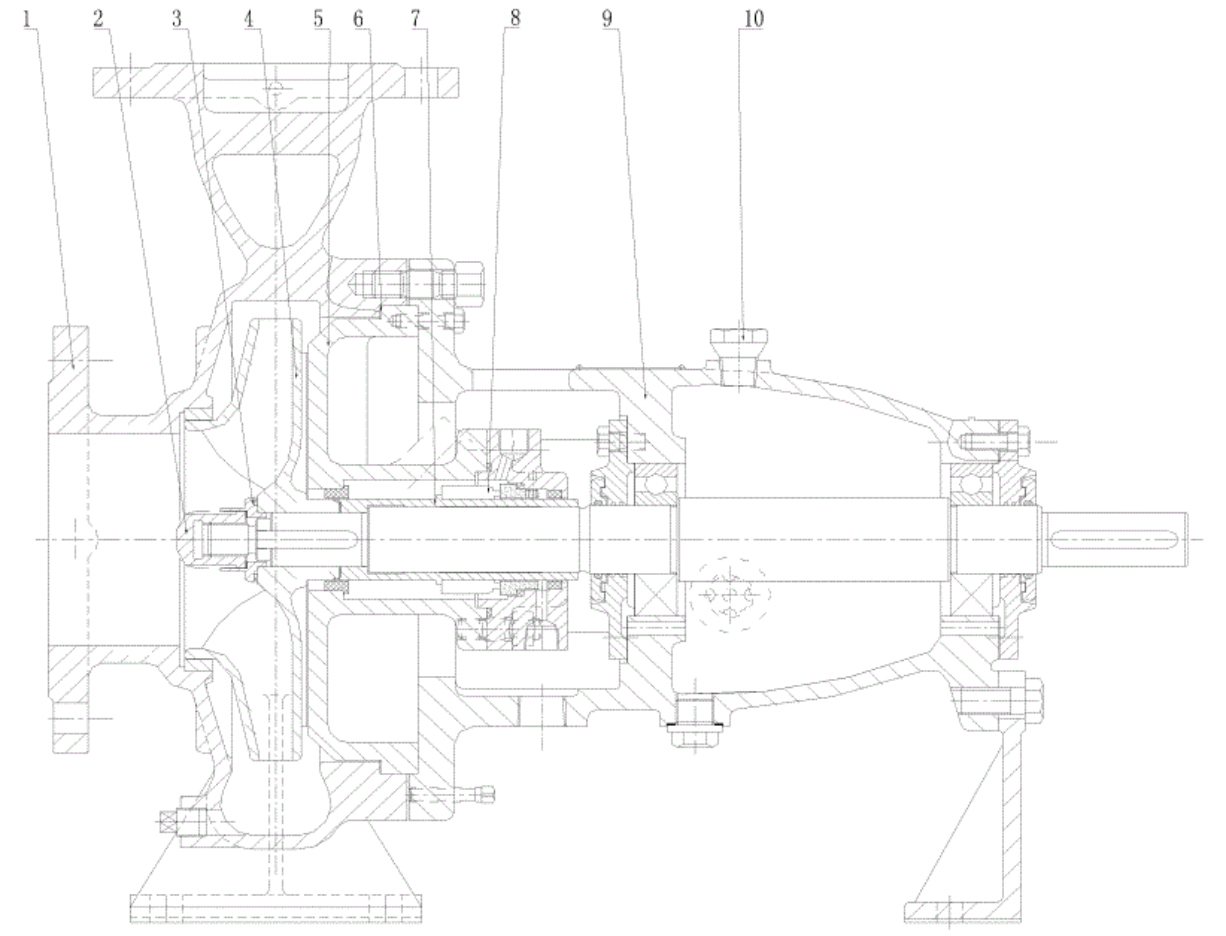

CZB型化工离心泵基本结构见“图一”;CZK型化工离心泵基本结构见“图二”;CZN型泵见“图三”。

泵叶轮的旋转方向:从驱动端看为顺时针方向旋转。

泵的结构特点:整体轴承架与泵体通过配合止口将泵盖夹紧。泵体为轴向吸入径向排出,支撑方式为脚支承。泵体支脚与悬架支架将泵牢固地支撑在底座上。

CZK型化工离心泵中有一前盖板通过螺栓固定于泵体上,前盖板和泵体之间用O形橡胶密封圈密封。叶轮与前盖板之间的间隙调整在0.3~0.5毫米内。个别CZK型化工离心泵无前盖板结构,叶轮与泵体配合面之间的间隙同上。

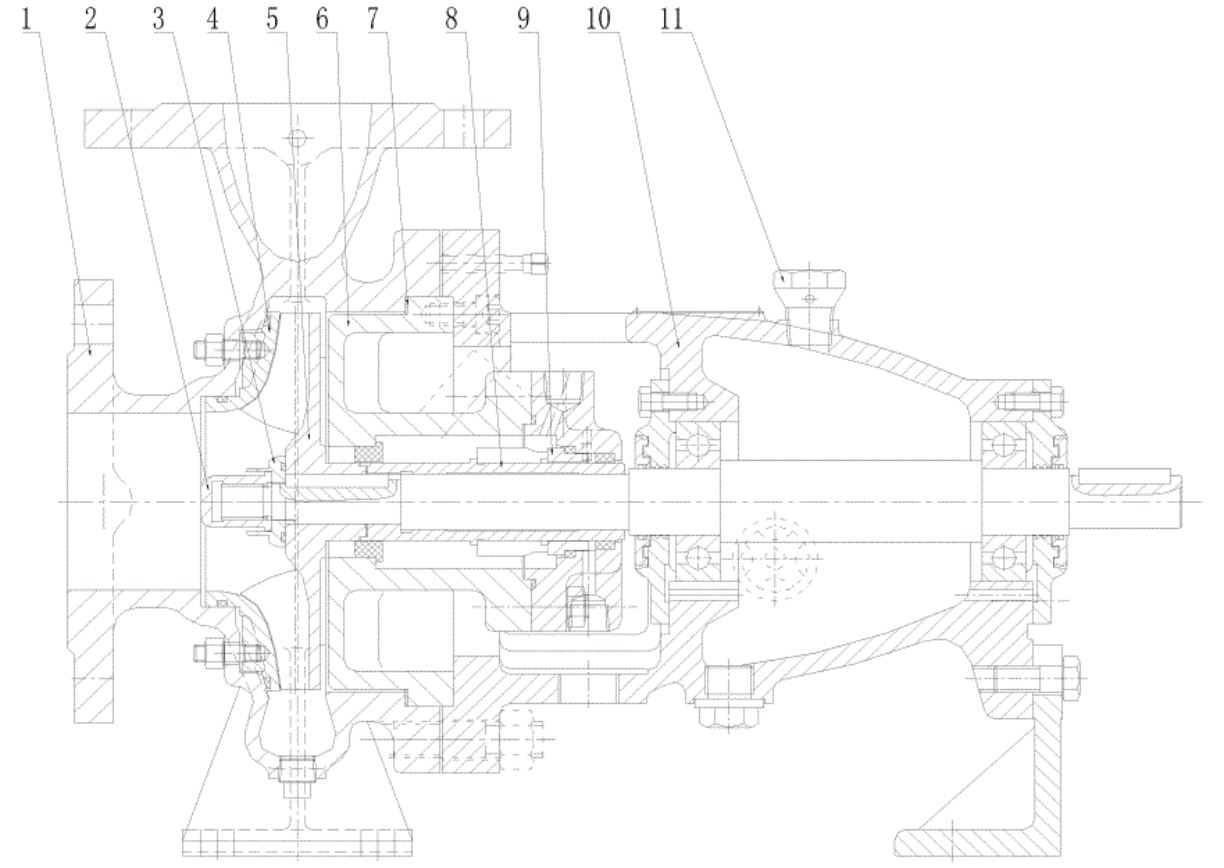

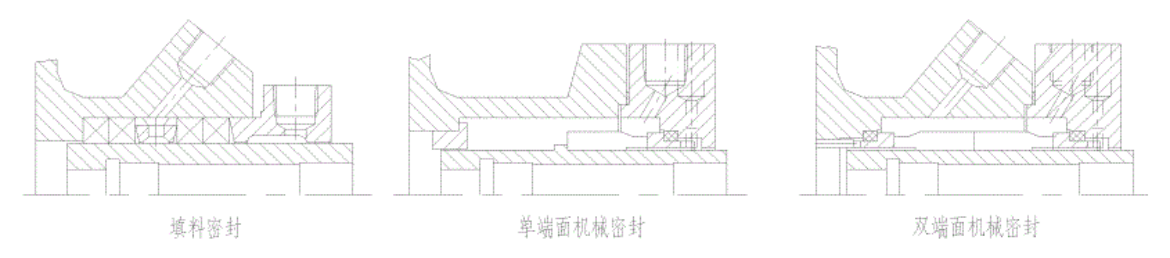

轴密封有软填料密封、单端面机械密封、双端面机械密封(见图四)

出口直径在80毫米口径以上泵体设计成双蜗壳结构,使液体作用在叶轮上的径向力始终处于平衡状态,最大限度地延长了机械密封和轴承的使用寿命。

图一

1、泵体 2、*叶轮螺母 3、*止动卡盘 4、叶轮 5、泵盖 6、*密封垫

7、*轴套 8、密封部件 9、轴承架部件 10、放气塞 11、(带“*”零件为易损件)

CZ标准化工泵装配与拆卸

泵的拆卸:

拧下“泵体”、“密封端盖”上的放液管堵和“轴承架”上的放油管堵,放净泵内液体及轴承架内的润滑油,如有外部密封管路也应拆下。

★注意:如果输送介质为高温、有毒、腐蚀性、易燃易爆液体应采取安全防护措施。

如有加长联轴器,则应拆开加长联轴器的中间联轴节。如配带的联轴器为梅花形弹性联轴器,则应移动电动机(100~140毫米)留下取出转子部件的空间。

松开“泵体”与“轴承架”联接螺栓,通过拆卸螺钉抽出轴承架部件、密封部件等转子部件。

用改锥或其它类似的工具解除“止动卡盘”对“叶轮螺母”防松措施。

松开“泵盖”与“轴承架”的定位连接螺栓,将“泵盖”连同“轴套”、“机械密封”、“密封端盖”等组件一起从轴上取下,拆卸时应均匀用力,尽量避免轴套与泵盖间产生相对滑动,损坏机械密封组件。然后,松开螺母取下“密封端盖”,将机械密封和轴套一起从泵盖密封腔中取出,再将轴套与机械密封拆开。如果是软填料密封,可先从泵盖上取下轴套,再顺次拆下填料压盖和填料环等,对特殊结构的机械密封要注意其装拆方法。

图二

1、泵体 2、*叶轮螺母 3、*止动卡盘 4、*前盖板 5、叶轮 6、泵盖

7、*密封垫 8、轴承 9、密封部件 10、轴承架部件 11、放气塞

带“*”的零件为易损件

图四

将悬架支架拆下。

拆下泵端联轴器和键。

拆下轴承架两端的“防尘盘”,“轴承前盖”、“轴承后盖”。再把轴连同轴承一起从轴承架中取出。

拆开轴承和轴,将拆下的轴承清洗干净并妥善保存。

如为有前盖板结构的CZK系列泵,应将前盖板从泵体中拆下。