您所在的位置:

- 上海美言壹泵阀有限公司

- 全国销售热线:

+86 21 5640 2009 - 水泵客服电话:

+86 138 1691 3072 - 阀门客服电话:

+86 1381 6913 072 - 企业电子邮箱:

my1pv@1bengfa.com

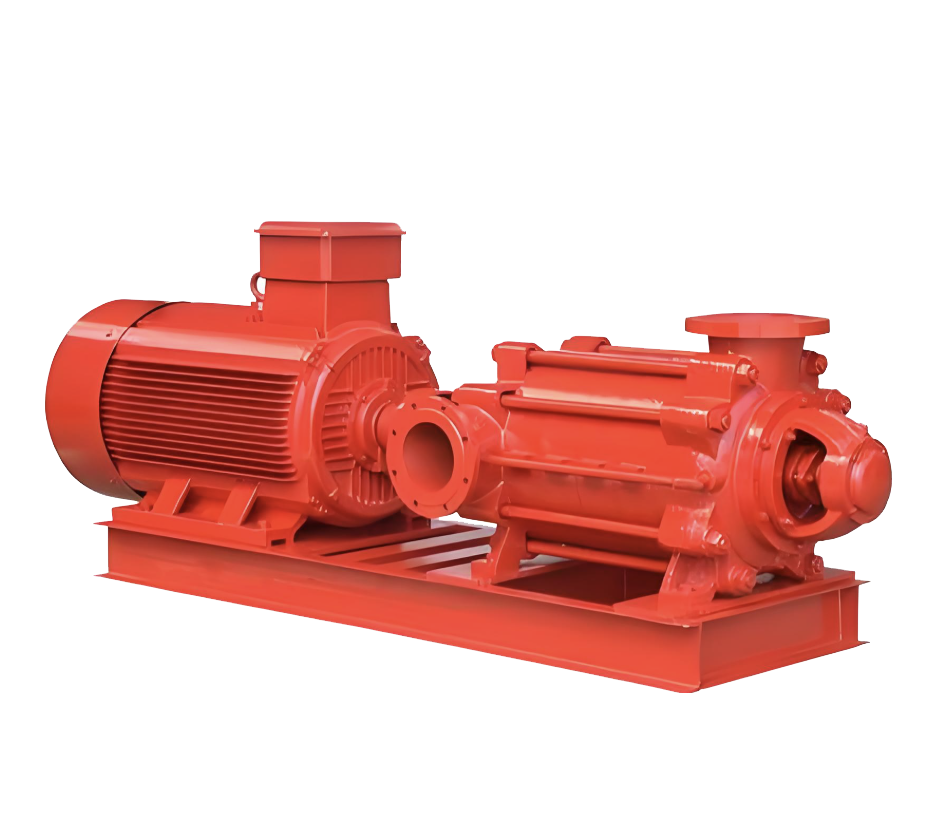

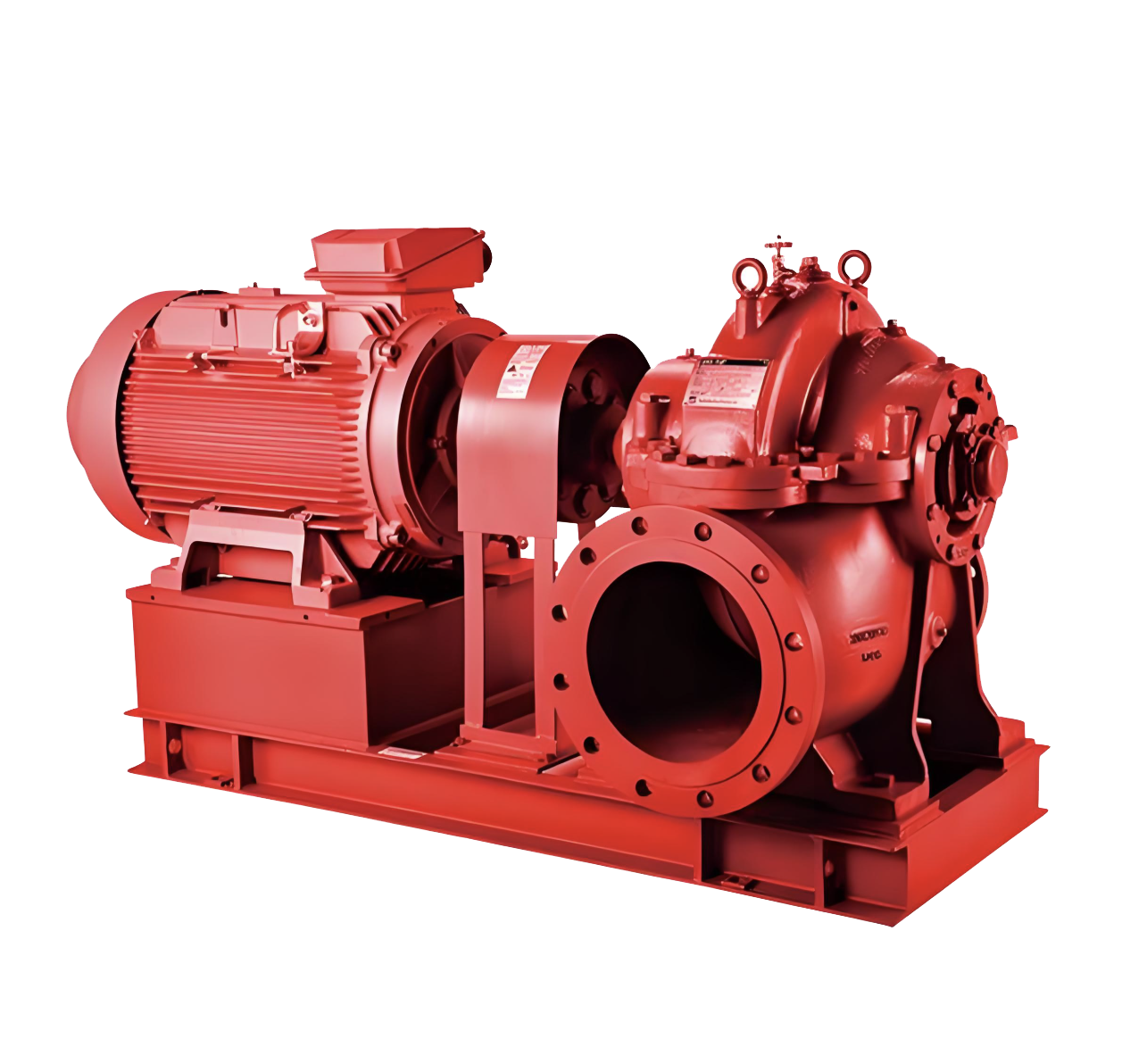

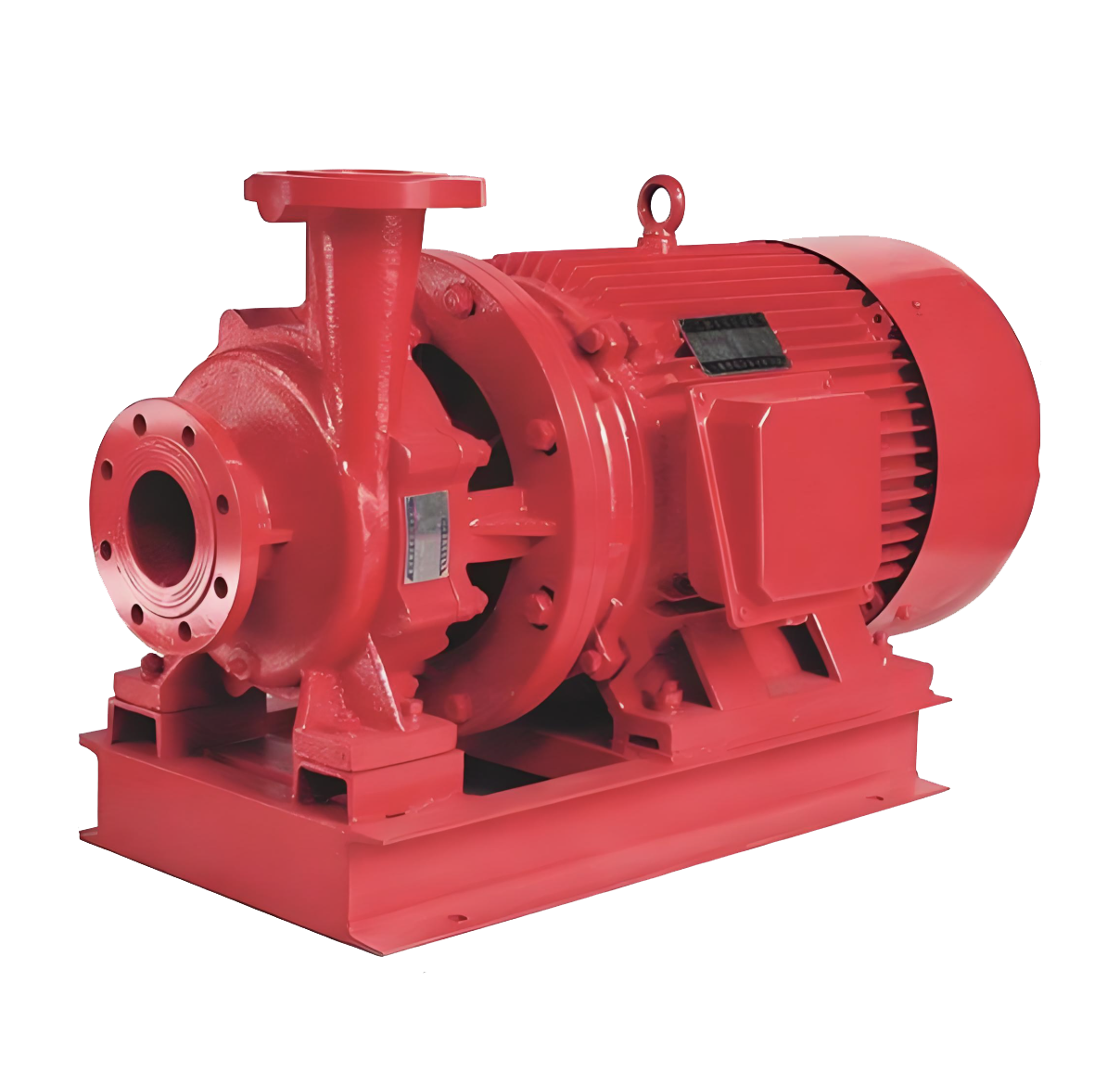

XBD(Ⅰ)-GDL多级管道消防泵

- 品牌:壹泵阀

- 型号:XBD-I、XBD-GDL

- 压力/扬程:33~230米

- 工作温度:0℃~80℃

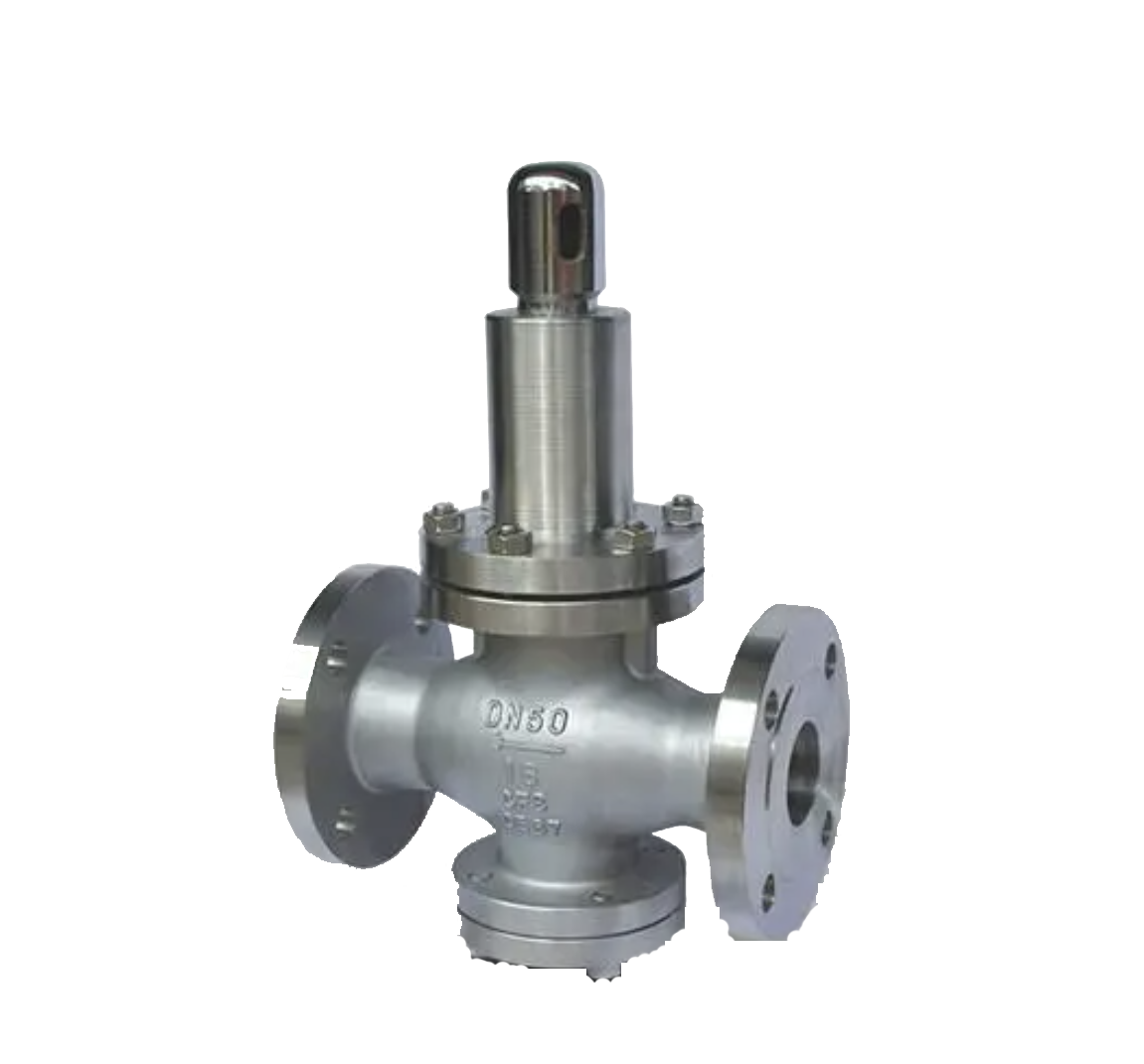

- 连接方式:法兰

- 产品名称:XBD(Ⅰ)-GDL多级管道消防泵

- 通径/流量:0.39~53.3L/S

- 材质:铸铁

- 驱动方式:电动、多级

- 适用范围:消防供水、消防稳压、消防增压等

- 产品概述

- 性能参数

- 尺寸重量

XBD(Ⅰ)-GDL多级管道消防泵

XBD(Ⅰ)-GDL多级管道消防泵产品简介

上海美言壹泵阀在原有立式多级泵基础上根据消防泵的最新标准要求进行开发出的新一代XBD(Ⅰ)-GDL立式多级管道型中低压消防泵组产品。XBD(Ⅰ)-GDL立式多级管道消防泵系列泵在性能、结构、材料和配套上均满足消防泵的要求。

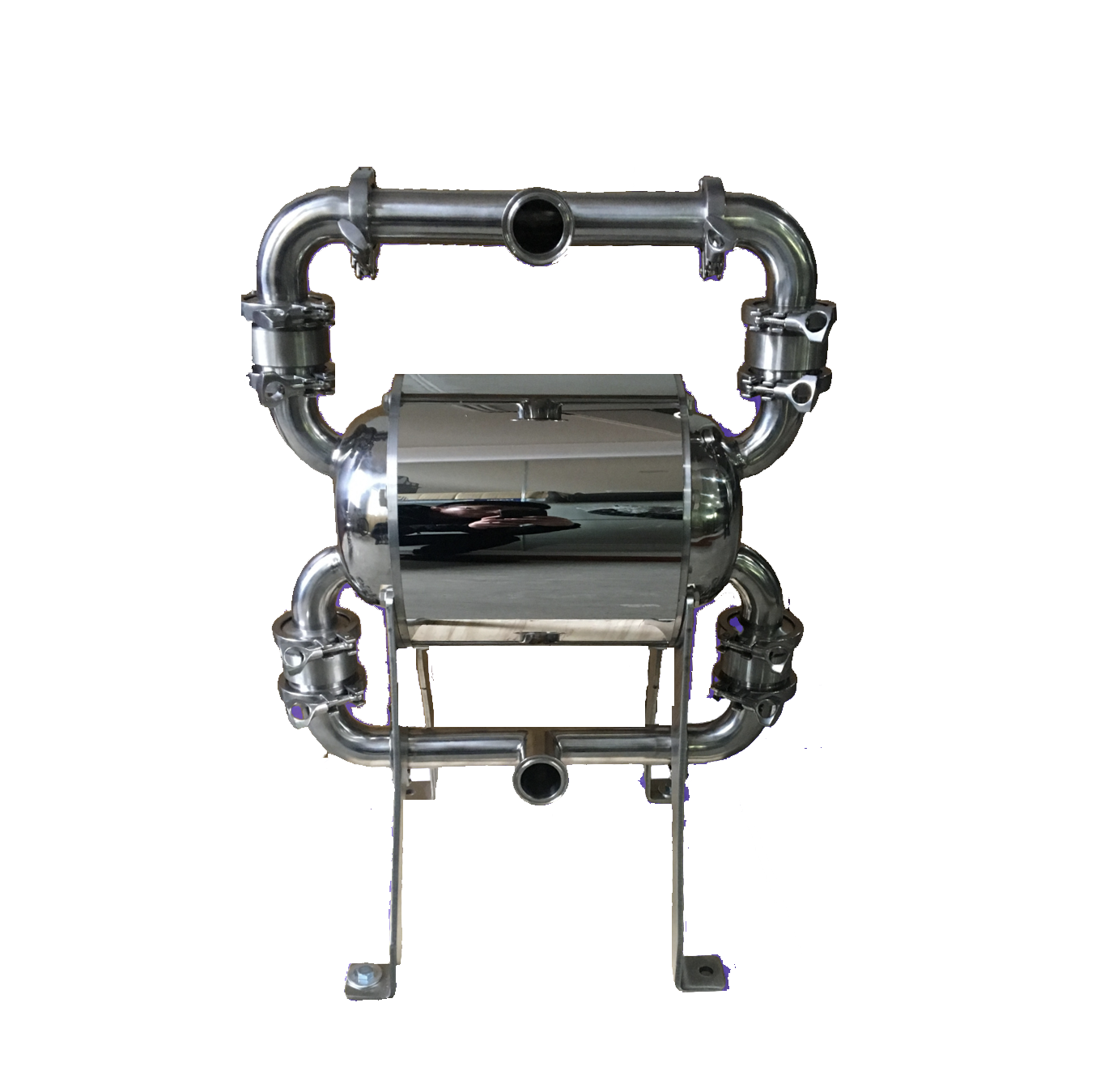

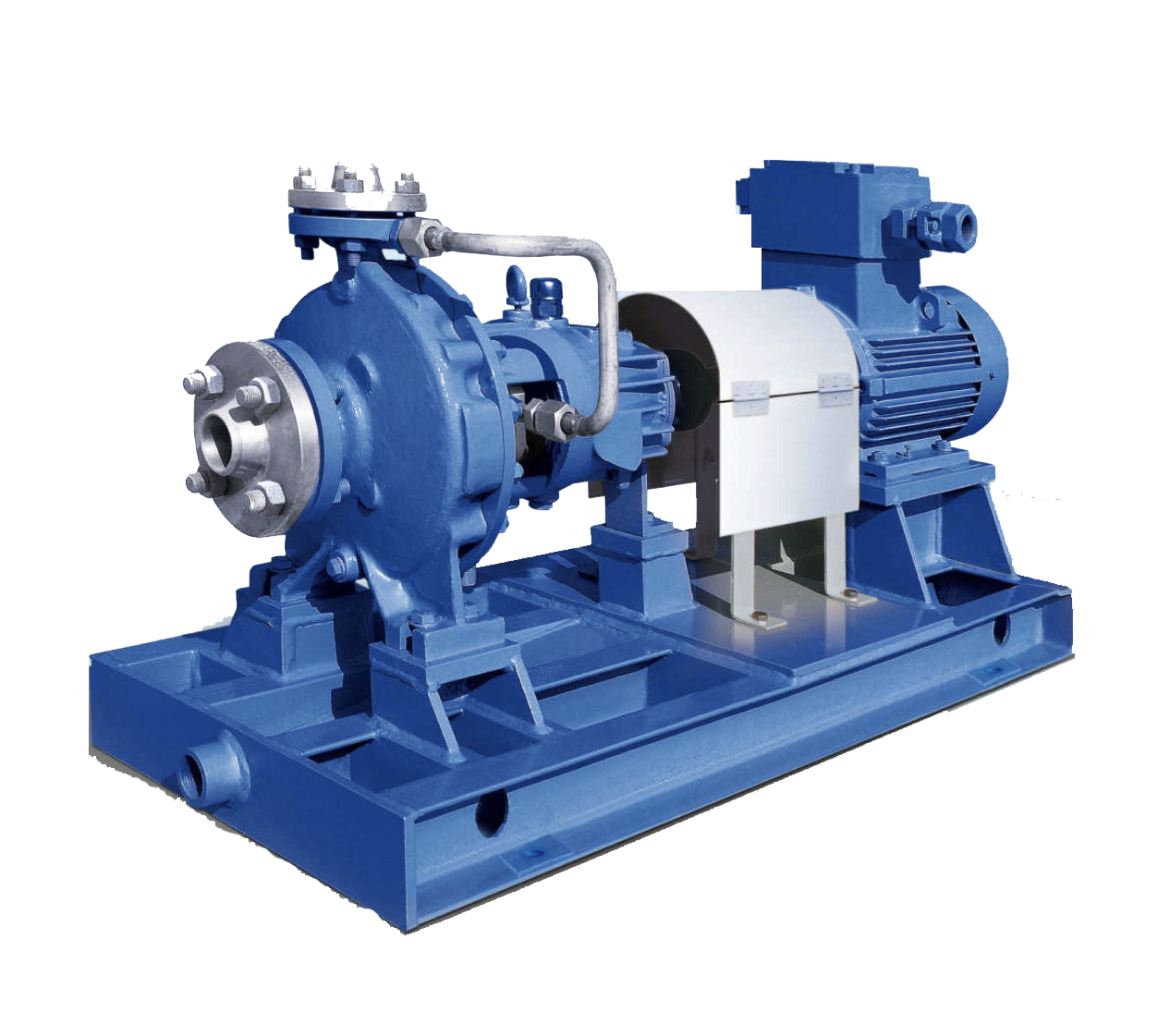

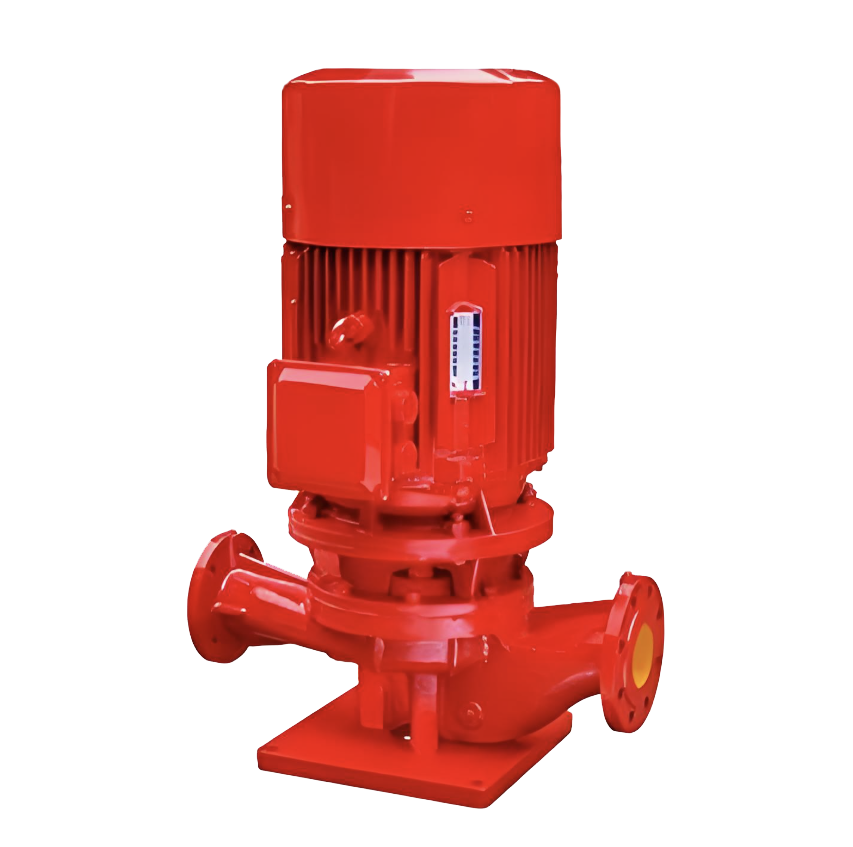

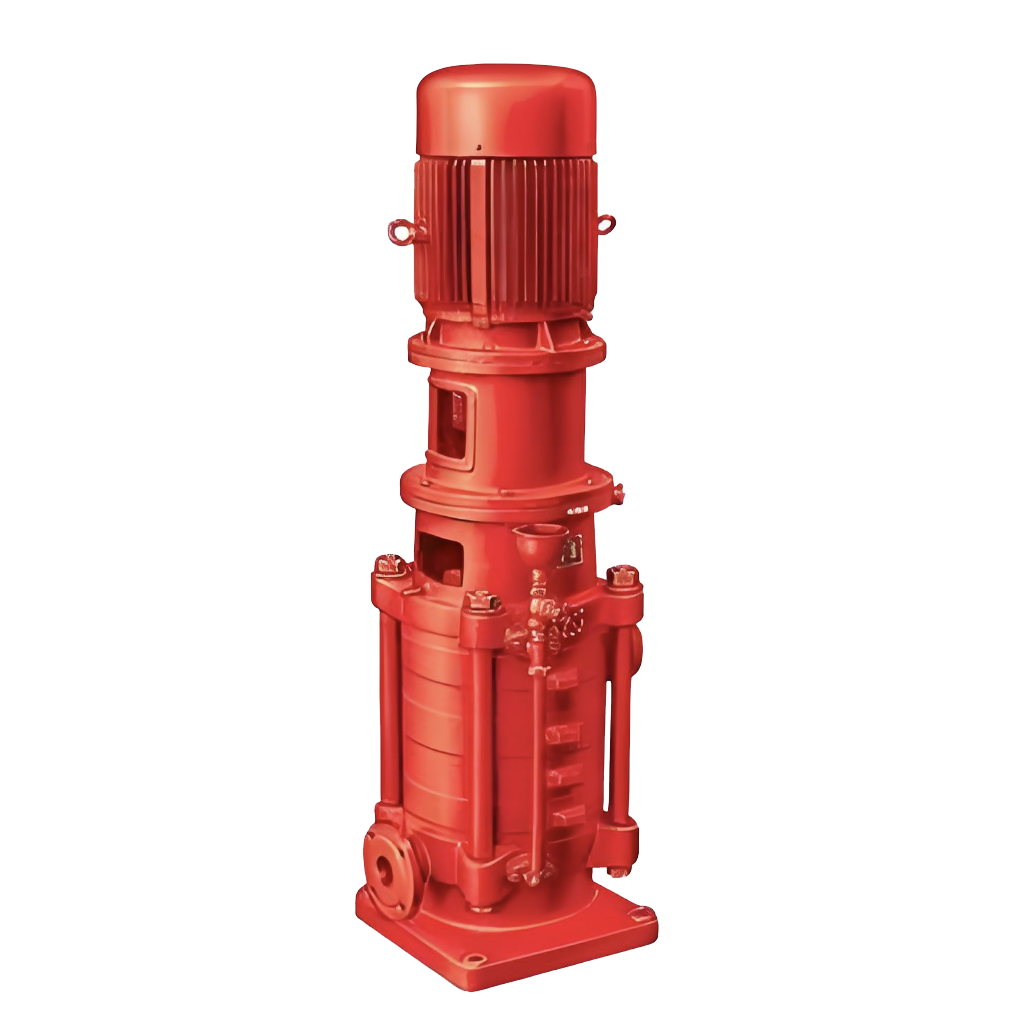

XBD(Ⅰ)-GDL多级管道消防泵产品图

XBD(Ⅰ)-GDL多级管道消防泵特点:

由于采用优秀的水力模型,因此该系列泵具有满足用户要求;

采用立式泵结构,具有效率高、性能范围广的特点,可更好地节省占地面积的优点;

采用优质轴承和优质电机,使泵运行更为安全可靠、噪声低、振动小;

采用水力平衡轴向力,减少平衡鼓,可使运行更为平稳;

其轴封有机械密封和填料密封两种形式;

该泵还具有进出水法兰管线布置、转速高、重量轻等特点。

XBD(Ⅰ)-GDL多级管道消防泵应用范围

适用于各种场合如住宅、宾馆、办公大楼、商业大楼、工厂、医院等处的消防给水。

XBD(Ⅰ)-GDL多级管道消防泵性能范围

流量:5~115L/S

扬程:20~230m

功率:3~200kw

XBD(Ⅰ)-GDL多级管道消防泵工作条件

1、 可输送清水或物理化学性质类似于清水的无腐蚀性介质,其固体不溶物不超过0.1%。

2、 介质温度:-15℃~120℃。

3、 最大工作压力:XBD型泵:≤2.5Mpa,即系统压力+扬程≤2.5Mpa,XBD(I)型泵:≤2.0Mpa。

4、 环境温度不大于40℃,相对湿度小于95%。

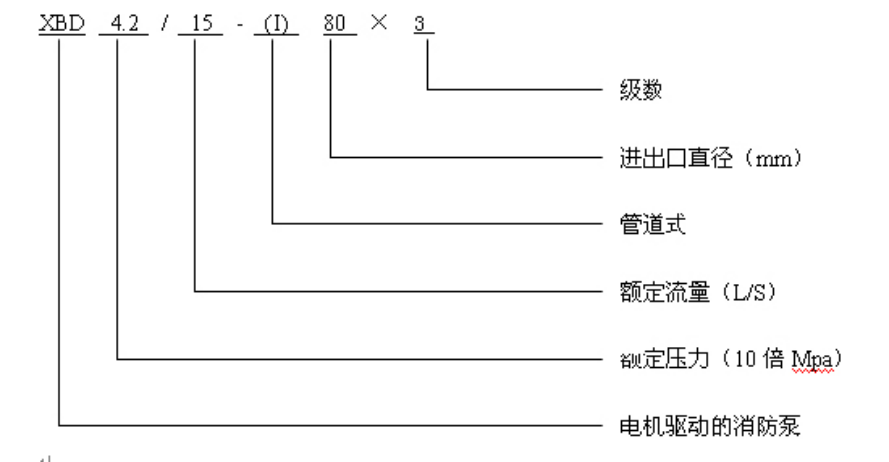

XBD(Ⅰ)-GDL多级管道消防泵型号意义

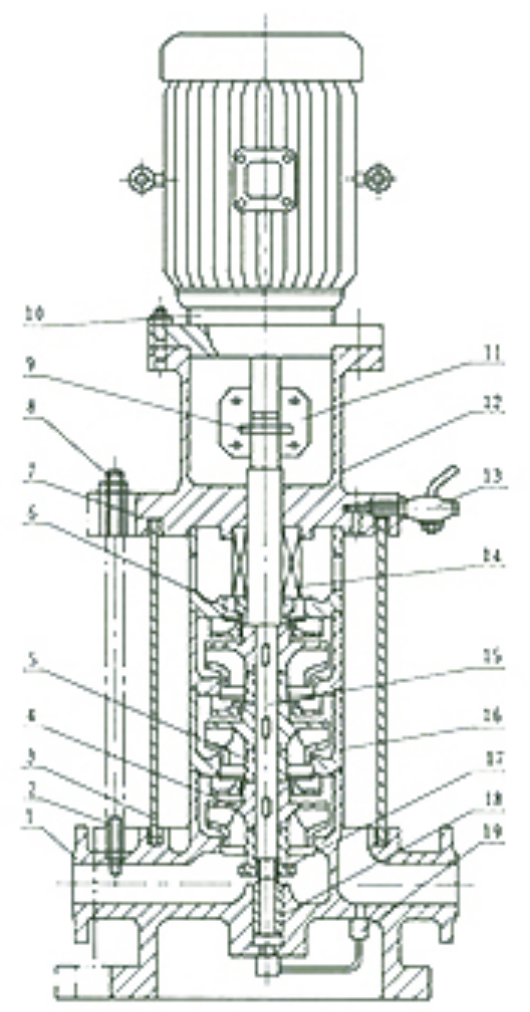

XBD(Ⅰ)-GDL多级管道消防泵结构图及零部件名称

| 1 | 泵 体 | 6 | 轴 套 | 11 | 联 轴 器 | 16 | 中 段 |

| 2 | 拉紧螺栓 | 7 | 密封垫 | 12 | 联 接 阀 | 17 | 轴套螺母 |

| 3 | 外 筒 | 8 | 螺 母 | 13 | 排 气 阀 | 18 | 轴 瓦 |

| 4 | 叶 轮 | 9 | 销 | 14 | 机械密封 | 19 | 回水管部件 |

| 5 | 叶轮挡套 | 10 | 电 机 | 15 | 轴 |

1、 该泵为立式、多级节段式结构,泵进出水法兰处在同一直线上,叶轮采用水力平衡方平衡轴向力。泵下端有一导轴承,轴通过夹壳联轴器与电机轴固定传动,外筒为不锈钢筒。

2、 轴封采用机械密封。

3、 泵由电机驱动,从电机端方向看,泵顺时针方向旋转。

4、 泵出口设有排气阀(气嘴),可保证泵内气体能完全排尽。

5、 叶轮可采用青铜材料,避免长期停机后叶轮与导叶间锈合。

XBD(Ⅰ)-GDL多级管道消防泵主要零件材料

| 零件名称 | 轴 封 | 轴 | 轴承体 | 联轴器 | 中 段 | 出水段 | 导 叶 | 叶 轮 | 轴套 | 进水段 |

| 材 质 | 填料、机械密封 | 2Cr13 | HT200 | HT200 | HT200 | HT200 | HT200 | HT200或青铜 | HT200 | HT200 |

| 零件名称 | 外 筒 | 螺母 | 连接座 | 轴 瓦 | ||||||

| 材 质 | ZG1Cr18Ni9Ti | 45 | HT200 | QSA4-3 |

XBD(Ⅰ)-GDL多级管道消防泵故障原因及排除方法

| 故障现象 | 可能产生的原因 | 排除方法 |

| A、水泵不出水 | 1、进出口阀门未打开,进出管路堵塞,叶轮流道堵塞2、电机运行方向不对,电机缺相转速很慢3、吸入管漏气4、泵没灌满液体,泵腔内有空气5、进口供水不足,吸程过高,底阀漏水6、管路阻力过大,泵选型不当 | 1、检查,去除阻塞物2、调整电机转向,紧固电机接线3、拧紧个密封面,排除空气4、打开排气阀,排尽空气5、停机检查、调整(并网自来水管和带吸程使用易出现此现象)6、减少管路弯道,重新选泵 |

| B、水泵流量不足 | 1、先按A、原因检查2、管道、泵流道或叶轮部分阻塞,水垢沉积、阀门开度不足3、电压偏低4、叶轮磨损 | 1、先按A、排除2、去除阻塞物,重新调整阀门开度3、稳压4、更换叶轮 |

| C、功率过大 | 1、超过额定流量使用2、吸程过高3、泵轴承磨损 | 1、调节流量,关小出口阀门2、降低吸程高度3、更换轴承 |

| D、杂音振动 | 1、管路支撑不稳2、液体混油气体3、产生气蚀4、轴承损坏5、电机超载运行 | 1、稳固管路2、提高吸入压力,排气3、降低真空度4、更换轴承5、调整按D、 |

| E、电机发热 | 1、流量过大,超载运行2、局部磨擦3、电机轴承损坏4、电压不足 | 1、关小出口阀门2、检查排除3、更换轴承4、稳压 |

| F、水泵漏水 | 1、机械密封磨损2、泵体有砂孔或破裂3、密封面不平整4、安装螺栓松懈 | 1、更换2、焊补或更换3、修整4、紧固 |

XBD(Ⅰ)-GDL多级管道消防泵型号及性能参数表

| 序号 | 型 号 | 流量Q | 扬程 | 效率 | 转速 | 功率(kw) | 气蚀余量m | 进出口径mm | 总高mm | 重量Kg | ||

| m3/h | L/S | m | % | r/min | 轴功率 | 电机功率 | ||||||

| 1 | XBD3.6/0.56-(I)25×3GDL | 1.422.4 | 0.390.560.67 | 383633 | 233032 | 2900 | 0.630.650.67 | 1.1 | 1.41.71.8 | 25 | 606 | 58 |

| 2 | XBD4.8/0.56-(I)25×4GDL | 1.422.4 | 0.390.560.67 | 504844 | 233032 | 2900 | 0.830.870.90 | 1.1 | 1.41.71.8 | 25 | 646 | 62 |

| 3 | XBD6/0.56-(I)25×5GDL | 1.422.4 | 0.390.560.67 | 636055 | 233032 | 2900 | 1.041.091.12 | 1.5 | 1.41.71.8 | 25 | 700 | 68 |

| 4 | XBD7.2/0.56-(I)25×6GDL | 1.422.4 | 0.390.560.67 | 767266 | 233032 | 2900 | 1.261.301.35 | 1.5 | 1.41.71.8 | 25 | 750 | 72 |

| 5 | XBD8.4/0.56-(I)25×7GDL | 1.422.4 | 0.390.560.67 | 888477 | 233032 | 2900 | 1.461.521.57 | 2.2 | 1.41.71.8 | 25 | 816 | 78 |

| 6 | XBD9.6/0.56-(I)25×8GDL | 1.422.4 | 0.390.560.67 | 1019688 | 233032 | 2900 | 1.631.741.80 | 2.2 | 1.41.71.8 | 25 | 856 | 82 |

| 7 | XBD10.8/0.56-(I)25×9GDL | 1.422.4 | 0.390.560.67 | 11410899 | 233032 | 2900 | 1.891.962.02 | 2.2 | 1.41.71.8 | 25 | 896 | 86 |

| 8 | XBD12/0.56-(I)25×10GDL | 1.422.4 | 0.390.560.67 | 126120110 | 233032 | 2900 | 2.012.172.24 | 3 | 1.41.71.8 | 25 | 981 | 98 |

| 9 | XBD13.2/0.56-(I)25×11GDL | 1.422.4 | 0.390.560.67 | 139132121 | 233032 | 2900 | 2.312.392.47 | 3 | 1.41.71.8 | 25 | 1021 | 102 |

| 10 | XBD14.4/0.56-(I)25×12GDL | 1.422.4 | 0.390.560.67 | 152144132 | 233032 | 2900 | 2.622.612.70 | 3 | 1.41.71.8 | 25 | 1061 | 106 |

| 11 | XBD3.3/1.11-(I)25×3 | 2.844.8 | 0.781.111.33 | 363328.5 | 324041 | 2900 | 0.860.900.91 | 1.1 | 1.41.71.8 | 25 | 606 | 58 |

| 12 | XBD4.4/1.11-(I)25×4 | 2.844.8 | 0.781.111.33 | 484438 | 324041 | 2900 | 1.141.201.21 | 1.5 | 1.41.71.8 | 25 | 671 | 65 |

| 13 | XBD5.5/1.11-(I)25×5 | 2.844.8 | 0.781.111.33 | 605547.5 | 324041 | 2900 | 1.431.501.51 | 2.2 | 1.41.71.8 | 25 | 736 | 72 |

| 14 | XBD6.6/1.11-(I)25×6 | 2.844.8 | 0.781.111.33 | 726657 | 324041 | 2900 | 1.721.801.82 | 2.2 | 1.41.71.8 | 25 | 776 | 76 |

| 15 | XBD7.7/1.11-(I)25×7 | 2.844.8 | 0.781.111.33 | 847766.5 | 324041 | 2900 | 2.002.102.12 | 2.2 | 1.41.71.8 | 25 | 816 | 86 |

| 16 | XBD8.8/1.11-(I)25×8 | 2.844.8 | 0.781.111.33 | 968876 | 324041 | 2900 | 2.292.402.42 | 3 | 1.41.71.8 | 25 | 901 | 90 |

| 17 | XBD9.9/1.11-(I)25×9 | 2.844.8 | 0.781.111.33 | 1089986.5 | 324041 | 2900 | 2.572.702.73 | 3 | 1.41.71.8 | 25 | 941 | 94 |

| 18 | XBD11/1.11-(I)25×10 | 2.844.8 | 0.781.111.33 | 12011095 | 324041 | 2900 | 2.863.003.03 | 4 | 1.41.71.8 | 25 | 1011 | 110 |

| 19 | XBD12.1/1.11-(I)25×11 | 2.844.8 | 0.781.111.33 | 132121104.5 | 324041 | 2900 | 3.143.303.33 | 4 | 1.41.71.8 | 25 | 1051 | 114 |

| 20 | XBD13.2/1.11-(I)25×12 | 2.844.8 | 0.781.111.33 | 144132114 | 324041 | 290 | 3.433.603.64 | 4 | 1.41.71.8 | 25 | 1091 | 118 |

| 21 | XBD14.3/1.11-(I)25×13 | 2.844.8 | 0.781.111.33 | 156143123.5 | 324041 | 2900 | 3.723.903.94 | 4 | 1.41.71.8 | 25 | 1131 | 122 |

| 22 | XBD3.6/1.67-(I)40×3 | 4.267.2 | 1.171.672.0 | 413630.5 | 435252 | 2900 | 1.091.131.15 | 1.5 | 1.41.71.8 | 40 | 657 | 72 |

| 23 | XBD4.8/1.67-(I)40×4 | 4.267.2 | 1.171.672.0 | 544840.6 | 435252 | 2900 | 1.451.51.53 | 2.2 | 1.41.71.8 | 40 | 622 | 78 |

| 24 | XBD6/1.67-(I)40×5 | 4.267.2 | 1.171.672.0 | 686051 | 435252 | 2900 | 1.811.881.92 | 2.2 | 1.41.71.8 | 40 | 762 | 82 |

| 25 | XBD7.2/1.67-(I)40×6 | 4.267.2 | 1.171.672.0 | 827261 | 435252 | 2900 | 2.182.262.30 | 3 | 1.41.71.8 | 40 | 847 | 92 |

| 26 | XBD8.4/1.67-(I)40×7 | 4.267.2 | 1.171.672.0 | 958471 | 435252 | 2900 | 2.542.642.69 | 3 | 1.41.71.8 | 40 | 887 | 96 |

| 27 | XBD9.6/1.67-(I)40×8 | 4.267.2 | 1.171.672.0 | 1099681 | 435252 | 2900 | 2.913.013.07 | 4 | 1.41.71.8 | 40 | 967 | 112 |

| 28 | XBD10.8/1.67-(I)40×9 | 4.267.2 | 1.171.672.0 | 12310891 | 435252 | 2900 | 3.273.393.45 | 4 | 1.41.71.8 | 40 | 1007 | 116 |

| 29 | XBD12/1.67-(I)40×10 | 4.267.2 | 1.171.672.0 | 136120102 | 435252 | 2900 | 3.633.773.84 | 4 | 1.41.71.8 | 40 | 1047 | 120 |

| 30 | XBD13.2/1.67-(I)40×11 | 4.267.2 | 1.171.672.0 | 150132112 | 435252 | 2900 | 4.04.154.22 | 5.5 | 1.41.71.8 | 40 | 1132 | 140 |

| 31 | XBD14.4/1.67-(I)40×12 | 4.267.2 | 1.171.672.0 | 164144122 | 435252 | 2900 | 4.364.524.60 | 5.5 | 1.41.71.8 | 40 | 1172 | 146 |

| 32 | XBD3/3.33-(I)50×2 | 8.41214.4 | 2.333.334.0 | 363024 | 485653 | 2900 | 1.721.751.85 | 2.2 | 1.41.81.8 | 50 | 766 | 113 |

| 33 | XBD4.5/3.33-(I)50×3 | 8.41214.4 | 2.333.334.0 | 544536 | 485653 | 2900 | 2.572.632.78 | 3 | 1.41.81.8 | 50 | 866 | 129 |

| 34 | XBD6.0/3.33-(I)50×4 | 8.41214.4 | 2.333.334.0 | 726048 | 485653 | 2900 | 3.433.63.70 | 4 | 1.41.81.8 | 50 | 1001 | 149 |

| 35 | XBD7.5/3.33-(I)50×5 | 8.41214.4 | 2.333.334.0 | 907560 | 485653 | 2900 | 4.24.274.63 | 5.5 | 1.41.81.8 | 50 | 1126 | 181 |

| 36 | XBD9/3.33-(I)50×6 | 8.41214.4 | 2.333.334.0 | 1089072 | 485653 | 2900 | 5.155.255.55 | 5.5 | 1.41.81.8 | 50 | 1201 | 190 |

| 37 | XBD10.5/3.33-(I)50×7 | 8.41214.4 | 2.333.334.0 | 12610584 | 485653 | 2900 | 6.06.126.48 | 7.5 | 1.41.81.8 | 50 | 1276 | 204 |

| 38 | XBD12/3.33-(I)50×8 | 8.41214.4 | 2.333.334.0 | 14412096 | 485653 | 2900 | 6.867.07.40 | 7.5 | 1.41.81.8 | 50 | 1351 | 212 |

| 39 | XBD13.5/3.33-(I)50×9 | 8.41214.4 | 2.333.334.0 | 162135108 | 485653 | 2900 | 7.727.878.33 | 11 | 1.41.81.8 | 50 | 1556 | 265 |

| 40 | XBD15/3.33-(I)50×10 | 8.41214.4 | 2.333.334.0 | 180150120 | 485653 | 2900 | 8.588.759.26 | 11 | 1.41.81.8 | 50 | 1631 | 273 |

| 41 | XBD3/5-(I)50×2 | 12.61821.6 | 3.556 | 363025 | 536262 | 2900 | 2.332.372.37 | 3 | 1.41.81.8 | 50 | 791 | 122 |

| 42 | XBD4.5/5-(I)50×3 | 12.61821.6 | 3.556 | 544537.5 | 536262 | 2900 | 3.53.563.56 | 4 | 1.41.81.8 | 50 | 926 | 142 |

| 43 | XBD6/5-(I)50×4 | 12.61821.6 | 3.556 | 726050 | 536262 | 2900 | 4.664.754.75 | 5.5 | 1.41.81.8 | 50 | 1051 | 175 |

| 44 | XBD7.5/5-(I)50×5 | 12.61821.6 | 3.556 | 907562.5 | 536262 | 2900 | 5.835.935.93 | 7.5 | 1.41.81.8 | 50 | 1126 | 189 |

| 45 | XBD9/5-(I)50×6 | 12.61821.6 | 3.556 | 1089075 | 536262 | 2900 | 7.07.127.12 | 7.5 | 1.41.81.8 | 50 | 1201 | 198 |

| 46 | XBD10.5/5-(I)50×7 | 12.61821.6 | 3.556 | 126105.587.5 | 536262 | 2900 | 8.168.308.31 | 11 | 1.41.81.8 | 50 | 1406 | 252 |

| 47 | XBD12/5-(I)50×8 | 12.61821.6 | 3.556 | 144120100 | 536262 | 2900 | 9.329.499.49 | 11 | 1.41.81.8 | 50 | 1481 | 261 |

| 48 | XBD13.5/5-(I)50×9 | 12.61821.6 | 3.556 | 162135112.5 | 536262 | 2900 | 10.7910.6810.68 | 11 | 1.41.81.8 | 50 | 1556 | 280 |

| 49 | XBD15/5-(I)50×10 | 12.61821.6 | 3.556 | 180150125 | 536262 | 2900 | 11.6611.8711387 | 15 | 1.41.81.8 | 50 | 1631 | 289 |

| 50 | XBD2.4/10-(I)80×2 | 25.23643.2 | 71012 | 272421 | 596867 | 2900 | 3.143.463.68 | 4 | 3.544.2 | 80 | 917 | 193 |

| 51 | XBD3.6/10-(I)80×3 | 25.23643.2 | 71012 | 40.53631.5 | 596867 | 2900 | 4.715.195.53 | 5.5 | 3.544.2 | 80 | 1052 | 227 |

| 52 | XBD4.8/10-(I)80×4 | 25.23643.2 | 71012 | 544842 | 596867 | 2900 | 6.296.927.37 | 7.5 | 3.544.2 | 80 | 1137 | 244 |

| 53 | XBD6/10-(I)80×5 | 25.23643.2 | 71012 | 67.56052.5 | 596867 | 2900 | 7.868.679.22 | 11 | 3.544.2 | 80 | 1352 | 292 |

| 54 | XBD7.2/10-(I)80×6 | 25.23643.2 | 71012 | 817263 | 596867 | 2900 | 9.4310.3911.06 | 11 | 3.544.2 | 80 | 1437 | 302 |

| 55 | XBD8.4/10-(I)80×7 | 25.23643.2 | 71012 | 94.58473.5 | 596867 | 2900 | 11.012.1212.9 | 15 | 3.544.2 | 80 | 1522 | 322 |

| 56 | XBD9.6/10-(I)80×8 | 25.23643.2 | 71012 | 1089684 | 596867 | 2900 | 12.5813.8514.75 | 15 | 3.544.2 | 80 | 1607 | 332 |

| 57 | XBD10.8/10-(I)80×9 | 25.23643.2 | 71012 | 121.510894.5 | 596867 | 2900 | 14.1415.5916.5 | 18.5 | 3.544.2 | 80 | 1737 | 365 |

| 58 | XBD12/10-(I)80×10 | 25.23643.2 | 71012 | 135120105 | 596867 | 2900 | 15.7117.3118.4 | 18.5 | 3.544.2 | 80 | 1822 | 375 |

| 59 | XBD2.8/15-(I)80×2 | 37.85464.8 | 10.51518 | 322825 | 627073.5 | 2900 | 5.325.886.01 | 7.5 | 3.744.2 | 80 | 967 | 218 |

| 60 | XBD4.2/15-(I)80×3 | 37.85464.8 | 10.51518 | 484237.5 | 627073.5 | 2900 | 7.978.829.01 | 11 | 3.744.2 | 80 | 1182 | 267 |

| 61 | XBD5.6/15-(I)80×4 | 37.85464.8 | 10.51518 | 645650 | 627073.5 | 2900 | 10.1311.7612.01 | 15 | 3.744.2 | 80 | 1267 | 287 |

| 62 | XBD7/15-(I)80×5 | 37.85464.8 | 10.51518 | 807062.5 | 627073.5 | 2900 | 13.314.715.0 | 18.5 | 3.744.2 | 80 | 1397 | 320 |

| 63 | XBD8.4/15-(I)80×6 | 37.85464.8 | 10.51518 | 968475 | 627073.5 | 2900 | 15.917.6418.0 | 18.5 | 3.744.2 | 80 | 1482 | 330 |

| 64 | XBD9.8/15-(I)80×7 | 37.85464.8 | 10.51518 | 1129887.5 | 627073.5 | 2900 | 18.620.5821.0 | 22 | 3.744.2 | 80 | 1592 | 373 |

| 65 | XBD11.2/15-(I)80×8 | 37.85464.8 | 10.51518 | 128112100 | 627073.5 | 2900 | 21.323.5424.0 | 30 | 3.744.2 | 80 | 1607 | 400 |

| 66 | XBD12.6/15-(I)80×9 | 37.85464.8 | 10.51518 | 144126112.5 | 627073.5 | 2900 | 23.926.4927.0 | 30 | 3.744.2 | 80 | 1757 | 421 |

| 67 | XBD14/15-(I)80×10 | 37.85464.8 | 10.51518 | 160140125 | 627073.5 | 2900 | 26.629.4330.0 | 37 | 3.744.2 | 80 | 1882 | 432 |

| 68 | XBD2.8/20-(I)100×2 | 50.47286.4 | 142024 | 322824 | 647373 | 2900 | 6.877.537.74 | 11 | 4.24.54.7 | 100 | 1200 | 276 |

| 69 | XBD4.2/20-(I)100×3 | 50.47286.4 | 142024 | 484236 | 647373 | 2900 | 10.311.2911.51 | 15 | 4.24.54.7 | 100 | 1335 | 298 |

| 70 | XBD5.6/20-(I)100×4 | 50.47286.4 | 142024 | 645648 | 647373 | 2900 | 13.715.0515.48 | 18.5 | 4.24.54.7 | 100 | 1460 | 336 |

| 71 | XBD7/20-(I)100×5 | 50.47286.4 | 142024 | 807060 | 647373 | 2900 | 17.1718.8119.35 | 22 | 4.24.54.7 | 100 | 1650 | 381 |

| 72 | XBD8.4/20-(I)100×6 | 50.47286.4 | 142024 | 968472 | 647373 | 2900 | 20.622.5723.22 | 30 | 4.24.54.7 | 100 | 1740 | 453 |

| 73 | XBD9.8/20-(I)100×7 | 50.47286.4 | 142024 | 1129884 | 647373 | 2900 | 24.0326.3427.09 | 30 | 4.24.54.7 | 100 | 1825 | 466 |

| 74 | XBD11.2/20-(I)100×8 | 50.47286.4 | 142024 | 12811296 | 647373 | 2900 | 27.430.130.96 | 37 | 4.24.54.7 | 100 | 1900 | 493 |

| 75 | XBD12.6/20-(I)100×9 | 50.47286.4 | 142024 | 144126108 | 647373 | 2900 | 30.933.934.83 | 37 | 4.24.54.7 | 100 | 1980 | 582 |

| 76 | XBD2.8/20-(I)100×10 | 50.47286.4 | 142024 | 160140120 | 647373 | 2900 | 34.337.638.7 | 45 | 4.24.54.7 | 100 | 2070 | 595 |

| 77 | XBD4.2 /25-(I)125×2 | 7090114 | 19.42531.6 | 464236 | 657373 | 2900 | 13.514.115.3 | 18.5 | 4.24.34.4 | 125 | 1185 | 292 |

| 78 | XBD6.3 /25-(I)125×3 | 7090114 | 19.42531.6 | 696354 | 657373 | 2900 | 20.221.222.9 | 30 | 4.24.34.4 | 125 | 1315 | 430 |

| 79 | XBD8.4 /25-(I)125×4 | 7090114 | 19.42531.6 | 928472 | 657373 | 2900 | 26.928.230.6 | 37 | 4.24.34.4 | 125 | 1410 | 463 |

| 80 | XBD10.5/25-(I)125×5 | 7090114 | 19.42531.6 | 11510690 | 657373 | 2900 | 33.735.338.2 | 45 | 4.24.34.4 | 125 | 1585 | 555 |

| 81 | XBD12.6 /25-(I)125×6 | 7090114 | 19.42531.6 | 138126108 | 657373 | 2900 | 40.440.345.9 | 55 | 4.24.34.4 | 125 | 1865 | 640 |

| 82 | XBD14.7 /25-(I)125×7 | 7090114 | 19.42531.6 | 161147126 | 657373 | 2900 | 47.149.453.5 | 55 | 4.24.34.4 | 125 | 1960 | 840 |

| 83 | XBD16.8 /25-(I)125×8 | 7090114 | 19.42531.6 | 184168144 | 657373 | 2900 | 53.956.461.1 | 75 | 4.24.34.4 | 125 | 2055 | 855 |

| 84 | XBD18.9 /25-(I)125×9 | 7090114 | 19.42531.6 | 207189102 | 657373 | 2900 | 60.663.568.7 | 75 | 4.24.34.4 | 125 | 2225 | 870 |

| 85 | XBD21 /25-(I)125×10 | 7090114 | 19.42531.6 | 230210180 | 657373 | 2900 | 67.370.676.4 | 90 | 4.24.34.4 | 125 | 2370 | 955 |

| 86 | XBD3.8 /30-(I)125×2 | 80108120 | 22.23033.3 | 443834 | 677473 | 2900 | 14.315.115.2 | 18.5 | 4.34.64.7 | 125 | 1185 | 292 |

| 87 | XBD5.7 /30-(I)125×3 | 80108120 | 22.23033.3 | 665751 | 677473 | 2900 | 21.522.722.8 | 30 | 4.34.64.7 | 125 | 1315 | 430 |

| 88 | XBD7.6 /30-(I)125×4 | 80108120 | 22.23033.3 | 887668 | 677473 | 2900 | 28.630.230.5 | 37 | 4.34.64.7 | 125 | 1410 | 463 |

| 89 | XBD9.5 /30-(I)125×5 | 80108120 | 22.23033.3 | 1109585 | 677473 | 2900 | 35.837.838.1 | 45 | 4.34.64.7 | 125 | 1585 | 555 |

| 90 | XBD11.4 /30-(I)125×6 | 80108120 | 22.23033.3 | 132114102 | 677473 | 2900 | 42.945.345.7 | 55 | 4.34.64.7 | 125 | 1865 | 640 |

| 91 | XBD13.3 /30-(I)125×7 | 80108120 | 22.23033.3 | 154133119 | 677473 | 2900 | 50.152.953.3 | 55 | 4.34.64.7 | 125 | 1960 | 840 |

| 92 | XBD15.2 /30-(I)125×8 | 80108120 | 22.23033.3 | 176152136 | 677473 | 2900 | 57.360.560.9 | 75 | 4.34.64.7 | 125 | 2055 | 855 |

| 93 | XBD17.1 /30-(I)125×9 | 80108120 | 22.23033.3 | 198171153 | 677473 | 2900 | 64.468.068.5 | 75 | 4.34.64.7 | 125 | 2225 | 870 |

| 94 | XBD19 /30-(I)125×10 | 80108120 | 22.23033.3 | 220190170 | 677473 | 2900 | 71.675.676.2 | 90 | 4.34.64.7 | 125 | 2370 | 955 |

| 95 | XBD4.3 /35-(I)150×2 | 112126160 | 31.33544.4 | 464340 | 697278 | 2900 | 20.520.522.3 | 30 | 4.44.44.5 | 150 | 1325 | 422 |

| 96 | XBD6.5 /35-(I)150×3 | 112126160 | 31.33544.4 | 696560 | 697278 | 2900 | 30.730.733.5 | 37 | 4.44.44.5 | 150 | 1420 | 452 |

| 97 | XBD8.7 /35-(I)150×4 | 112126160 | 31.33544.4 | 928780 | 697278 | 2900 | 40.940.944.7 | 45 | 4.44.44.5 | 150 | 1605 | 613 |

| 98 | XBD10.7 /35-(I)150×5 | 112126160 | 31.33544.4 | 115109100 | 697278 | 2900 | 51.251.255.9 | 75 | 4.44.44.5 | 150 | 1875 | 820 |

| 99 | XBD13.0 /35-(I)150×6 | 112126160 | 31.33544.4 | 138130120 | 697278 | 2900 | 61.461.467.1 | 75 | 4.44.44.5 | 150 | 1970 | 836 |

| 100 | XBD15.2 /35-(I)150×7 | 112126160 | 31.33544.4 | 161152140 | 697278 | 2900 | 71.671.678.3 | 90 | 4.44.44.5 | 150 | 2115 | 922 |

| 101 | XBD17.4 /35-(I)150×8 | 112126160 | 31.33544.4 | 184174160 | 697278 | 2900 | 81.981.989.4 | 90 | 4.44.44.5 | 150 | 2210 | 1198 |

| 102 | XBD19.6 /35-(I)150×9 | 112126160 | 31.33544.4 | 207196180 | 697278 | 2900 | 92.192.1100.6 | 110 | 4.44.44.5 | 150 | 2495 | 1214 |

| 103 | XBD21.8 /35-(I)150×10 | 112126160 | 31.33544.4 | 230218200 | 697278 | 2900 | 102.4102.4111.8 | 132 | 4.44.44.5 | 150 | 2670 | 1340 |

| 104 | XBD4.1 /40-(I)150×2 | 112144180 | 31.34050 | 464137 | 697678 | 2900 | 20.521.223.3 | 30 | 4.44.44.6 | 150 | 1325 | 422 |

| 105 | XBD6.2 /40-(I)150×3 | 112144180 | 31.34050 | 696255.5 | 697678 | 2900 | 30.732.034.6 | 37 | 4.44.44.6 | 150 | 1420 | 452 |

| 106 | XBD8.3 /40-(I)150×4 | 112144180 | 31.34050 | 928674 | 697678 | 2900 | 40.942.746.1 | 55 | 4.44.44.6 | 150 | 1705 | 613 |

| 107 | XBD10.4 /40-(I)150×5 | 112144180 | 31.34050 | 11510492.5 | 697678 | 2900 | 51.253.457.6 | 75 | 4.44.44.6 | 150 | 1875 | 820 |

| 108 | XBD12.4 /40-(I)150×6 | 112144180 | 31.34050 | 138124111 | 697678 | 2900 | 61.464.069.2 | 75 | 4.44.44.6 | 150 | 1970 | 836 |

| 109 | XBD14.5 /40-(I)150×7 | 112144180 | 31.34050 | 161145129.5 | 697678 | 2900 | 71.674.780.7 | 90 | 4.44.44.6 | 150 | 2115 | 922 |

| 110 | XBD16.6 /40-(I)150×8 | 112144180 | 31.34050 | 184166148 | 697678 | 2900 | 81.985.492.2 | 110 | 4.44.44.6 | 150 | 2400 | 1198 |

| 111 | XBD18.7 /40-(I)150×9 | 112144180 | 31.34050 | 207187166.5 | 697678 | 2900 | 92.196.0103.8 | 110 | 4.44.44.6 | 150 | 2495 | 1214 |

| 112 | XBD20.7 /40-(I)150×10 | 112144180 | 31.34050 | 230207185 | 697678 | 2900 | 102.4107.1115.3 | 132 | 4.44.44.6 | 150 | 2670 | 1340 |

| 113 | XBD4/45-(I)150×2 | 122162192 | 344553.3 | 444034 | 717877 | 2900 | 20.722.623.1 | 30 | 4.44.54.7 | 150 | 1325 | 422 |

| 114 | XBD6/45-(I)150×3 | 122162192 | 344553.3 | 666051 | 717877 | 2900 | 31.034.034.6 | 37 | 4.44.54.7 | 150 | 1420 | 452 |

| 115 | XBD8/45-(I)150×4 | 122162192 | 344553.3 | 888068 | 717877 | 2900 | 41.345.346.2 | 55 | 4.44.54.7 | 150 | 1705 | 613 |

| 116 | XBD10/45-(I)150×5 | 122162192 | 344553.3 | 11010085 | 717877 | 2900 | 51.756.657.8 | 75 | 4.44.54.7 | 150 | 1875 | 820 |

| 117 | XBD12/45-(I)150×6 | 122162192 | 344553.3 | 132120102 | 717877 | 2900 | 62.067.969.3 | 75 | 4.44.54.7 | 150 | 1970 | 836 |

| 118 | XBD14/45-(I)150×7 | 122162192 | 344553.3 | 154140119 | 717877 | 2900 | 72.379.280.9 | 90 | 4.44.54.7 | 150 | 2115 | 922 |

| 119 | XBD16/45-(I)150×8 | 122162192 | 344553.3 | 176160136 | 717877 | 2900 | 82.790.692.4 | 110 | 4.44.54.7 | 150 | 2400 | 1198 |

| 120 | XBD18/45-(I)150×9 | 122162192 | 344553.3 | 198180153 | 717877 | 2900 | 93.0101.9104.0 | 110 | 4.44.54.7 | 150 | 2495 | 1214 |

| 121 | XBD20/45-(I)150×10 | 122162192 | 344553.3 | 220200170 | 717877 | 2900 | 103.4113.2115.5 | 132 | 4.44.54.7 | 150 | 2670 | 1340 |

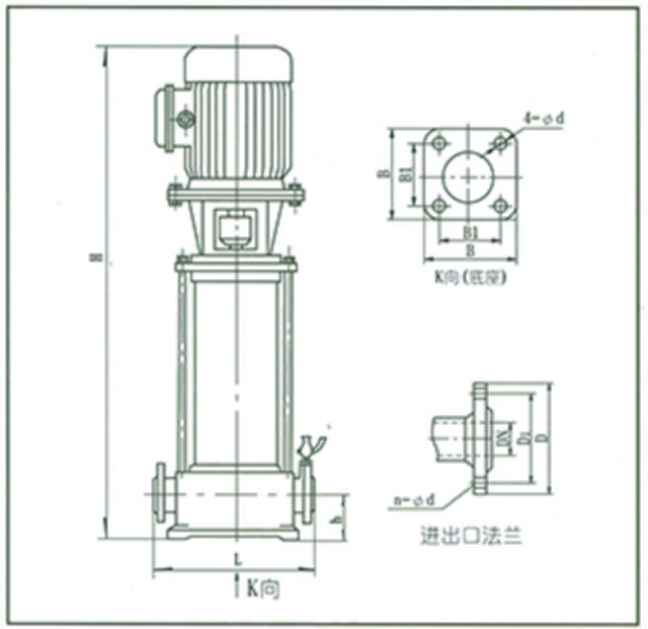

XBD(Ⅰ)-GDL多级管道消防泵外形尺寸图

XBD(Ⅰ)-GDL多级管道消防泵外形尺寸表

| 型号 | h | L | B1 | B | 4-фd | 进出口法兰 | |||

| DN | D1 | n-фd1 | D | ||||||

| XBD/0.56-(I)25XBD/1.11-(I)25 | 75 | 300 | 205 | 230 | 4-ф14 | 25 | 85 | 4-14 | 115 |

| XBD/1.67-(I)40 | 90 | 330 | 215 | 255 | 4-ф18 | 40 | 110 | 4-18 | 150 |

| XBD/3.33-(I)50XBD/5-(I)50 | 100 | 360 | 235 | 300 | 4-ф18 | 50 | 125 | 4-18 | 160 |

| XBD/10-(I)80XBD/15-(I)80 | 130 | 420 | 300 | 340 | 4-ф18 | 80 | 160 | 8-18 | 200 |

| XBD/20-(I)100 | 140 | 420 | 300 | 340 | 4-ф18 | 100 | 180 | 8-18 | 220 |

| XBD/25-(I)125XBD/30-(I)125 | 160 | 500 | 350 | 400 | 4-ф24 | 125 | 210 | 8-18 | 250 |

| XBD/35-(I)150XBD/40-(I)150 | 180 | 500 | 350 | 400 | 4-ф24 | 150 | 240 | 8-22 | 285 |

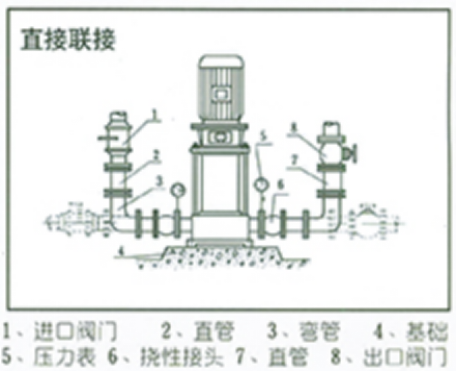

XBD(Ⅰ)-GDL多级管道消防泵基础安装示意图

XBD(I)型泵安装极为方便且占地面积小、外形美观大方、噪音低、振动小、效率高。

1、进口阀门 2、直管 3、弯管 4、基础 5、压力表 6、挠性接头 7、直管 8、出口阀门

1、进口阀门2、直管3、弯管4、隔振器5、基础6、联接板7、挠性接头8、直管9、出口阀门

1、进口阀门 2、直管 3、弯管 4、隔振垫 5、联接板 6、基础7、挠性接头8、出口阀门

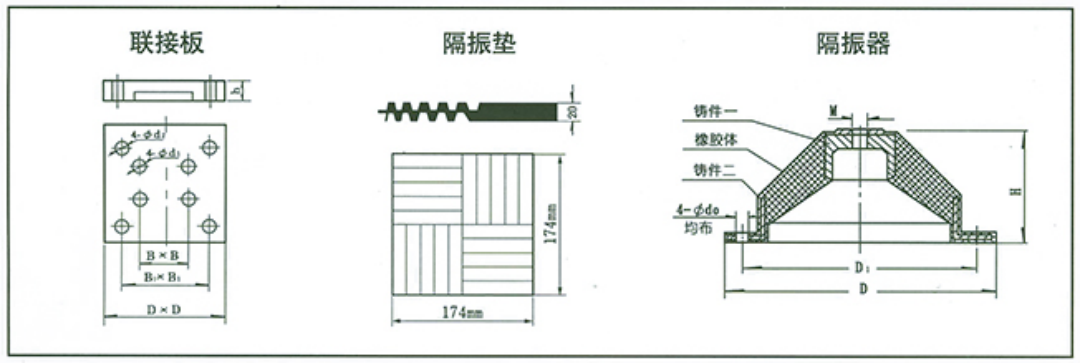

XBD(Ⅰ)-GDL多级管道消防泵附件尺寸图及尺寸表

| 泵口径 | 联 接 板 尺 寸 | 隔 振 器 尺 寸 | |||||||||||

| 型号 | D | h | B | B1 | d1 | d2 | 型号 | M | D | D1 | H | Фd0 | |

| 25 | 3# | 500 | 55 | 205 | 440 | 18 | 16 | JG2-1 | M12 | Ф150 | Ф130 | 65 | Ф8.5 |

| 40 | 3# | 500 | 55 | 215 | 440 | 18 | 16 | JG2-1 | M12 | Ф150 | Ф130 | 65 | Ф8.5 |

| 50 | 4# | 600 | 55 | 235 | 540 | 18 | 16 | JG2-2 | M12 | Ф150 | Ф130 | 65 | Ф8.5 |

| 80 | 5# | 700 | 55 | 300 | 640 | 18 | 18 | JG3-1 | M16 | Ф200 | Ф170 | 87 | Ф12.5 |

| 100 | 5# | 700 | 55 | 300 | 640 | 18 | 18 | JG3-2 | M16 | Ф200 | Ф170 | 87 | Ф12.5 |

| 125 | 6# | 800 | 55 | 350 | 740 | 18 | 20 | JG3-2 | M16 | Ф200 | Ф170 | 87 | Ф12.5 |

| 150 | 6# | 800 | 55 | 350 | 740 | 18 | 20 | JG4-1 | M20 | Ф200 | Ф260 | 133 | Ф12.5 |

XBD(Ⅰ)-GDL多级管道消防泵基础图及其联接尺寸

| 泵口径 | 直接安装基础尺寸 | 配联接板、隔振垫基础尺寸 | 配联接板、隔振垫基础尺寸 | 隔振器规 格 | ||||||||||||||||

| H | A | B | E | F | d | H | A | B | E | F | d | H | A | B | E | F | D | d | ||

| 25 | 200 | 150 | 205 | 500 | 550 | 60 | 200 | 150 | 440 | 750 | 800 | 60 | 200 | 60 | 440 | 750 | 800 | 130 | 8.5 | JG2-1 |

| 40 | 200 | 150 | 215 | 500 | 550 | 60 | 200 | 150 | 440 | 750 | 800 | 60 | 200 | 60 | 440 | 750 | 800 | 130 | 8.5 | JG2-1 |

| 50 | 250 | 200 | 235 | 550 | 600 | 60 | 250 | 200 | 540 | 850 | 900 | 60 | 250 | 60 | 540 | 850 | 900 | 130 | 8.5 | JG2-2 |

| 80 | 300 | 250 | 300 | 600 | 650 | 80 | 300 | 250 | 640 | 950 | 1050 | 80 | 300 | 60 | 640 | 950 | 1050 | 170 | 12.5 | JG3-1 |

| 100 | 300 | 250 | 300 | 600 | 650 | 80 | 300 | 250 | 640 | 950 | 1050 | 80 | 300 | 60 | 640 | 950 | 1050 | 170 | 12.5 | JG3-2 |

| 125 | 300 | 250 | 350 | 650 | 700 | 80 | 300 | 250 | 740 | 1050 | 1150 | 80 | 300 | 80 | 740 | 1050 | 1150 | 170 | 12.5 | JG3-2 |

| 150 | 300 | 250 | 350 | 650 | 700 | 80 | 300 | 250 | 740 | 1050 | 1150 | 80 | 300 | 80 | 740 | 1050 | 1150 | 260 | 12.5 | JG4-1 |

XBD(Ⅰ)-GDL多级管道消防泵安装说明

1、 安装时故那路重量不应承受在泵上,否则易损坏水泵;

2、 泵与电机是整体结构,出厂时已由厂家校正,所以安装时无需调整,因此安装时十分方便;

3、 安装时必须拧紧地脚螺栓,且每间隔一定时段应对泵进行检查防止其松动,以免水泵起动时发生剧烈振动而影响泵的性能;

4、 安装水泵前应仔细检查泵流道内有无影响水泵运行的硬质物(如石块、铁砂等)以免水泵运行时损坏过流部件;

5、 为了维护方便和使用安全,在泵的进出口管路上安装一只调节阀及在泵进出口附近安装一只压力表,对于高扬程泵,为防止水锤,还应在出口闸阀前安装一只止回阀以应付突然断电等失去动力事故,从而确保水泵在最佳工况下运行,增长水泵的使用寿命;

6、 泵用于有吸程场合,应装有 底阀,并且进口管路不应有过多弯道,同时不得有漏水、漏气现象,以免影响水泵的吸入性能;

7、 为了不使杂质进入泵内而堵塞流道影响性能,应在泵进口前面安装过滤器;

8、 安装管路前转动水泵的转子部件,应无磨擦声或卡死现象,否则应将泵拆开检查原因。

XBD(Ⅰ)-GDL多级管道消防泵维护与保养

运行中的维护与保养

1、 进水管路必须高度密封,不能漏水、漏气;

2、 禁止泵在气蚀状态下长期运行;

3、 禁止泵在大流量工况运行时,电机超电流长期运行;

4、 定时检查泵运行中的电机电流值,尽量使泵在设计工况范围内运行;

5、 泵在运行中应有专人看管,以免发生意外;

6、 泵进行长期运行后,由于机械磨损,使机组噪声及振动增大时,应停车检查,必要时可更换易损零件及轴承,机组检修期一般为一年。

机械密封维护与保养

1、 机械密封润滑应清洁无固体颗粒;

2、 严禁机械密封在干磨情况下工作;

3、 起动前应盘动泵(电机)几圈,以免突然起动造成机械密封断裂损坏。

XBD(Ⅰ)-GDL多级管道消防泵起动与停车

起动前准备

1、 用手拨转电机,叶轮应无卡磨现象,转动灵活;

2、 打开进口阀门,打开排气阀使液体充满整个泵腔,然后关闭排气阀;

3、 如输送热液体时,起动前应预热,升温速度为50℃/h,泵的预热是用所输送液体不断循环来达到,以使个部位受热均匀;

4、 应先用手盘动几圈以使润滑水进入机械密封端面;

5、 点动电机,确定转向是否正确。

起动与运行

1、 全开进口阀门,关闭吐出管路发阀门;

2、 接通电源,当泵达到正常转速后,再逐渐打开吐出管路上的阀门,并调节到所需工况;

3、 注意观察仪表读数,检查轴封泄漏情况,正常时机械密封泄漏为3滴/分,检查电机、轴承处温升≤70℃,如果发现异常情况,应及时处理。

停车

1、 逐渐关闭吐出管路阀门,切断电源;

2、 关闭进口阀门;

3、 如环境温度低于0℃,应将泵内液体放尽,以免冻裂水泵;

4、 如长期停用,应将泵拆卸清洗,包装保管。