您所在的位置:

- 上海美言壹泵阀有限公司

- 全国销售热线:

+86 21 5640 2009 - 水泵客服电话:

+86 138 1691 3072 - 阀门客服电话:

+86 1381 6913 072 - 企业电子邮箱:

my1pv@1bengfa.com

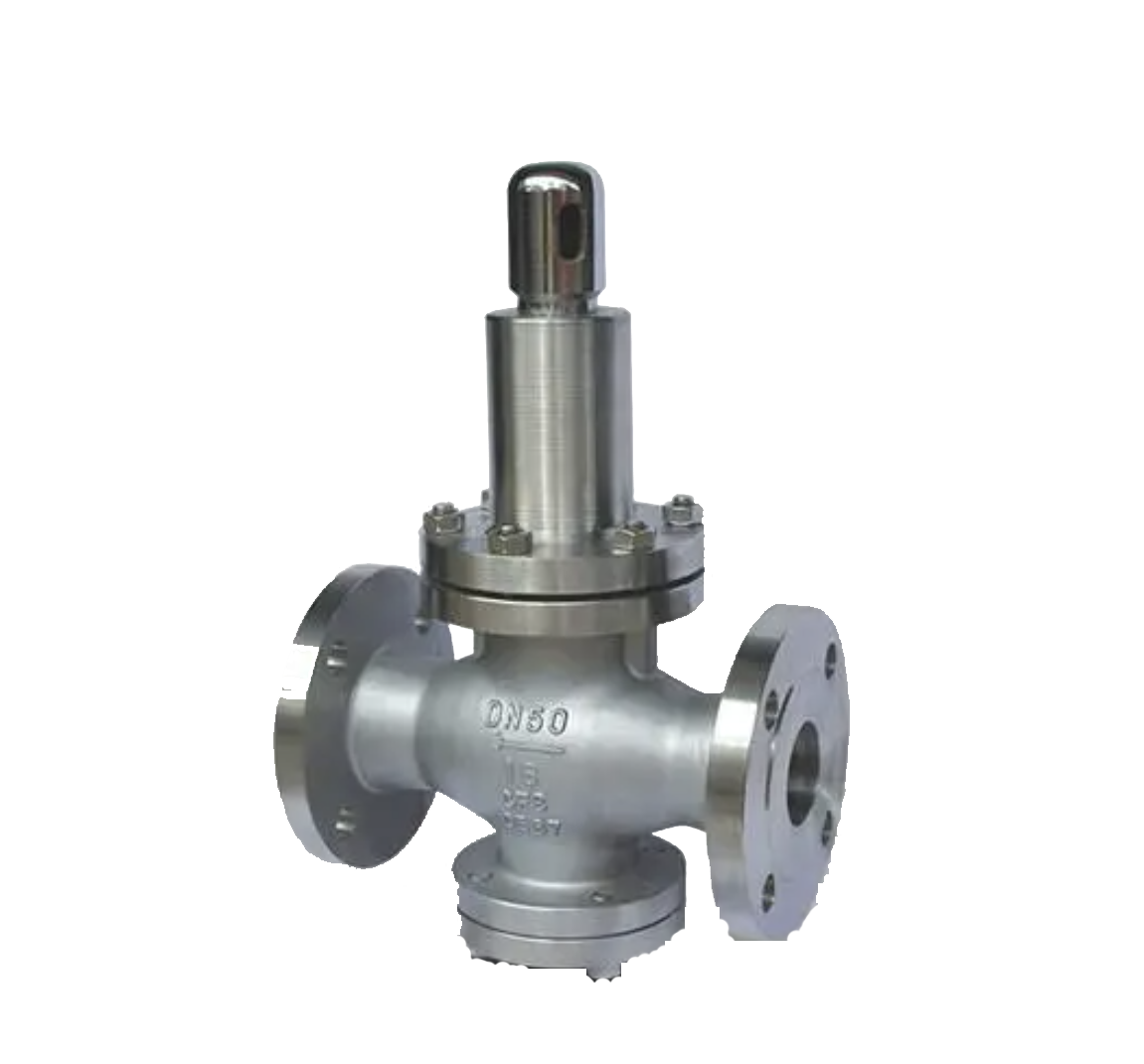

IH不锈钢离心泵

- 品牌:壹泵阀

- 型号:IH

- 压力/扬程:5~125米

- 工作温度:-20℃~120℃

- 连接方式:法兰

- 产品名称:IH不锈钢离心泵

- 通径/流量:6.3~400吨/每小时

- 材质:不锈钢SS304、SS304L、SS316、SS316L

- 驱动方式:电动

- 适用范围:类似于水的腐蚀性介质。

- 产品概述

- 性能参数

- 尺寸重量

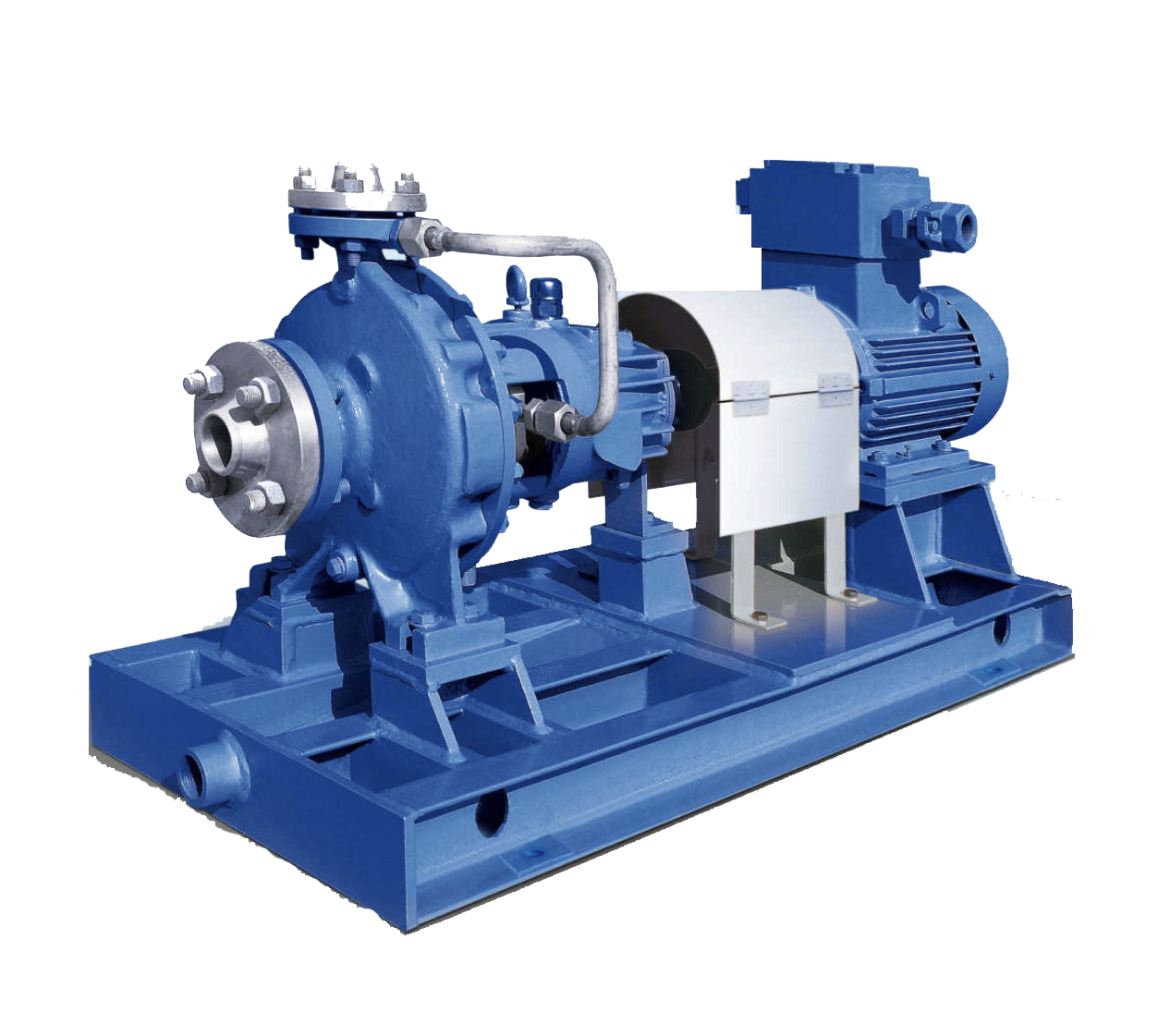

IH不锈钢离心泵

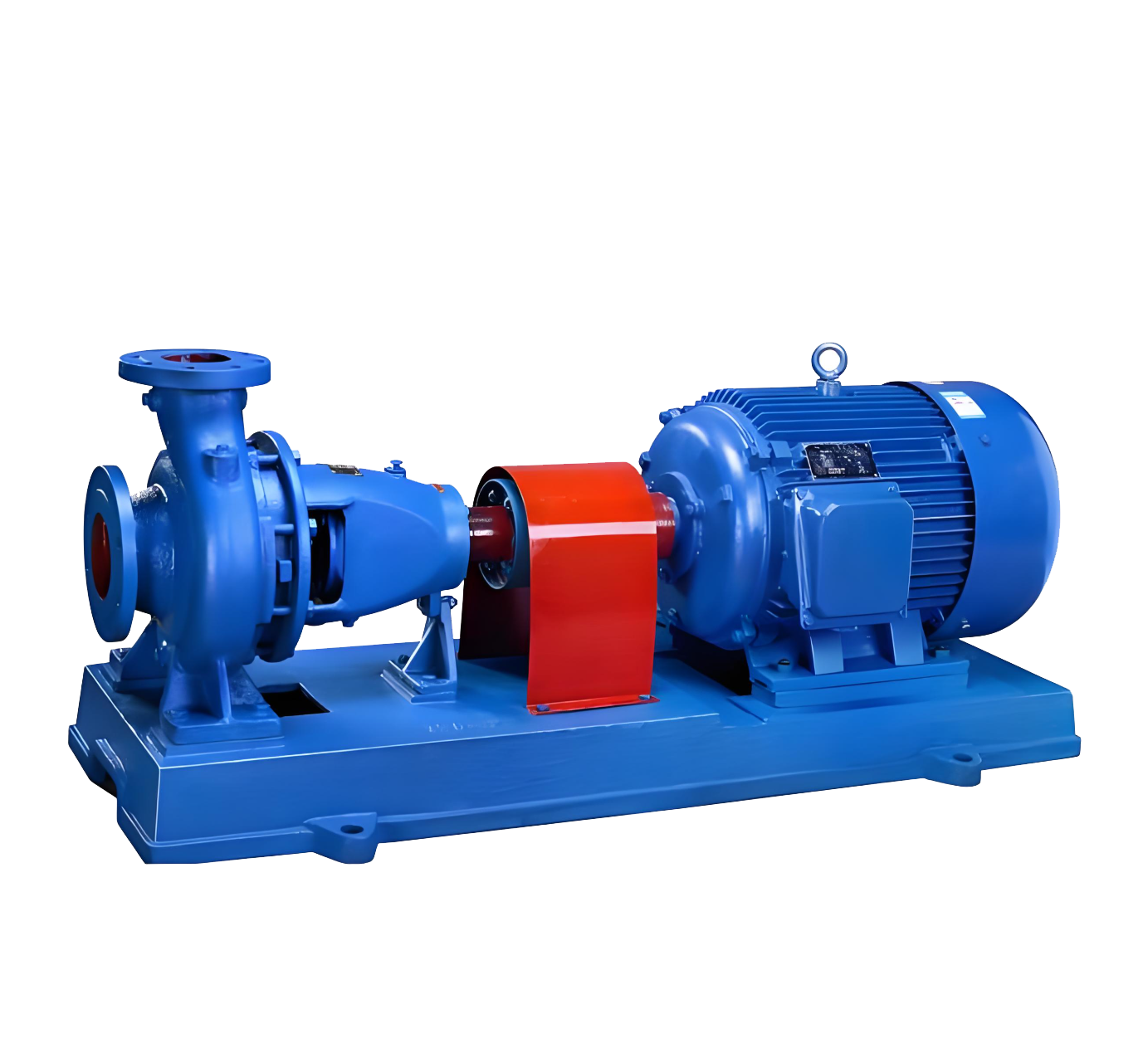

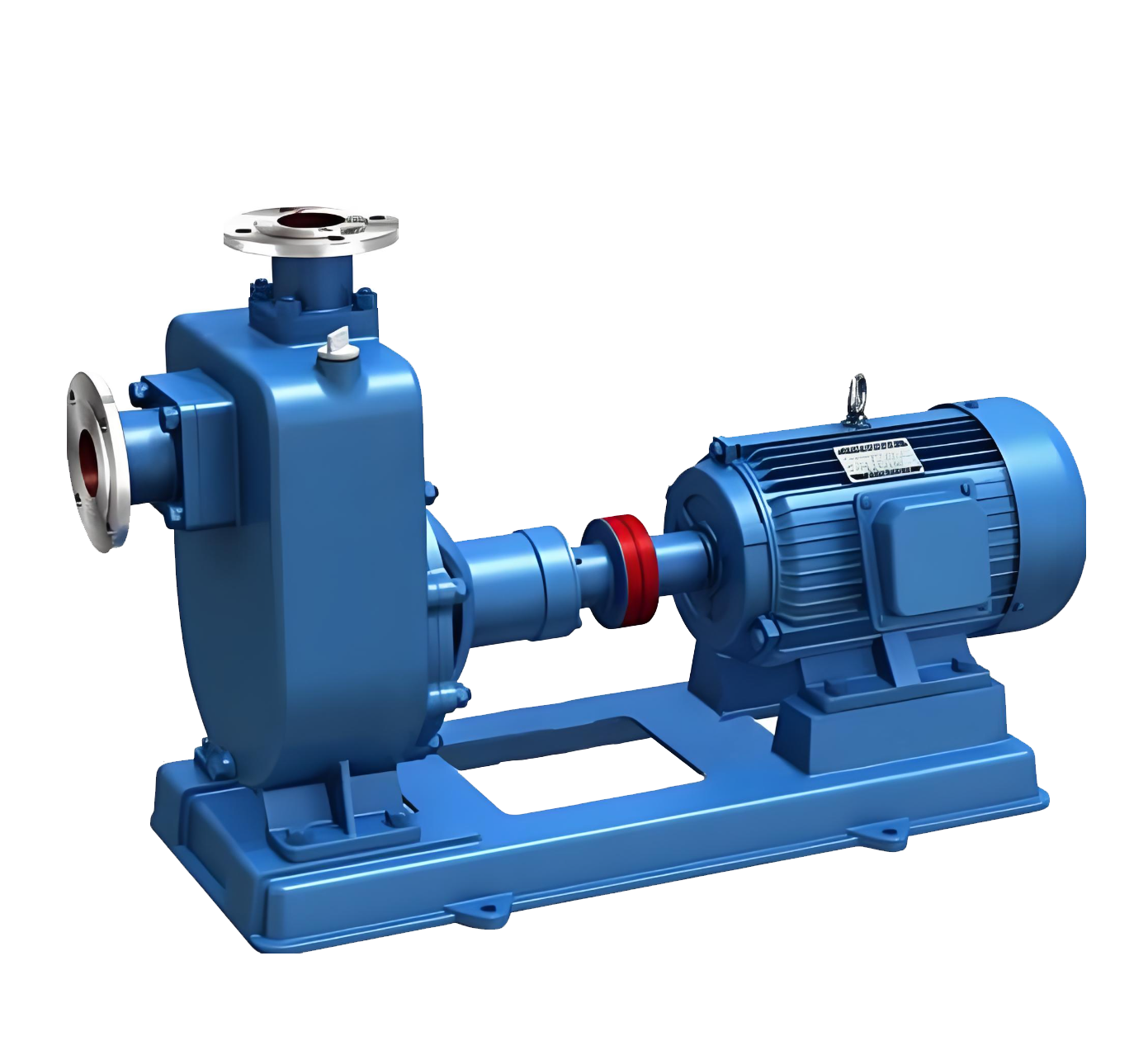

IH不锈钢离心泵概述

IH不锈钢离心泵为单级单吸悬臂式化工离心泵。其标记,额定性能点和尺寸等效采用国际标准 ISO2858-1975(E),是机械工业部确定取代F型耐腐蚀离心泵的节能、更新换代产品。能满足化工程中输送有腐蚀性粘度类似于水的液体。

泵输送介质的温度一般为-20℃~105℃,必要时采用适当冷却措施,输送的介质温度可更高。

泵的最高工作压力按1.6MPa设计本系列泵的性能范围(设计点):流量为6.3~400m'/h,扬程为5~125m。根据所输送介质对泵腐蚀的情况,用户可选用相适应的触液部分的材质。泵与介质接触的主要零件材质如下表所示:

表一材质及代号表

| 材质 | ZG1Cr18Ni9 | ZG1Cr18NiOTi | ZGOCr18NiMo2Ti | ZG1Cr18NiMo | ZG1Cr18Mn13M0.2CuN |

| 代号 | 303 | 305 | 306 | 307 | 402 |

除上述所列材料外,允许用户根据需要选择适合本系列泵生产的材质。材料及其代号原则上应符合GB2100标准的规定。对国家没有规定代号的材质可采用国际通用的材料代号或国内公认的材料代号(如行业或本企业的规定)。

IH型化工泵适应区域广泛,如化工、冶金、电力、造纸、食品、制药、合成等工业部门输送腐蚀性的或不允许污染的介质。

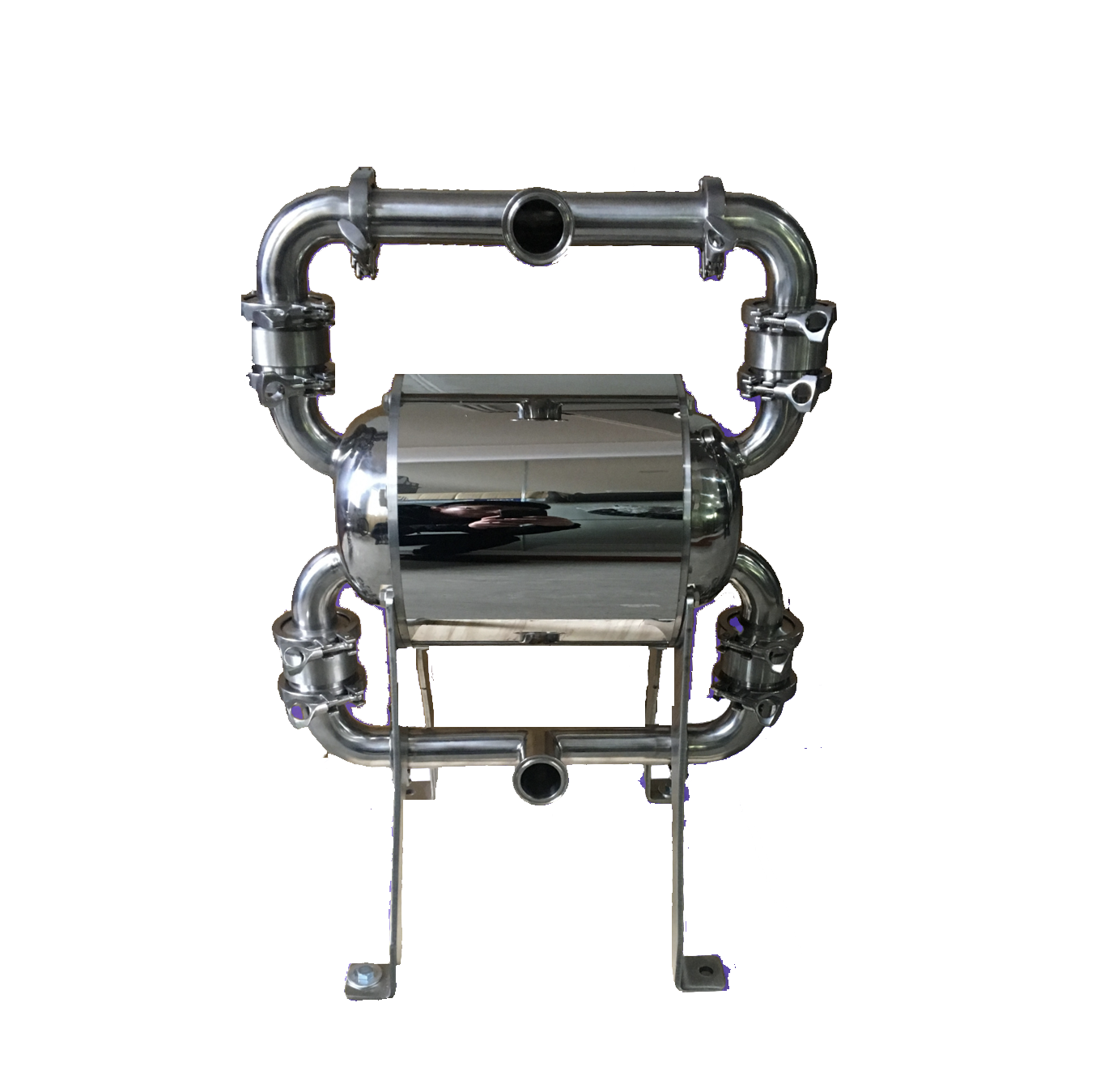

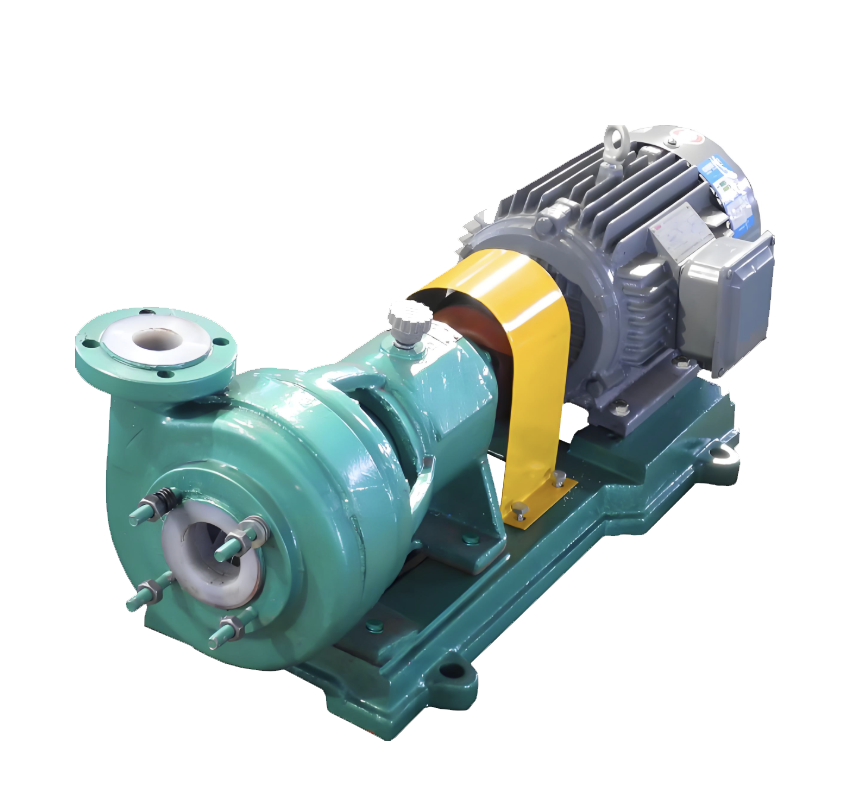

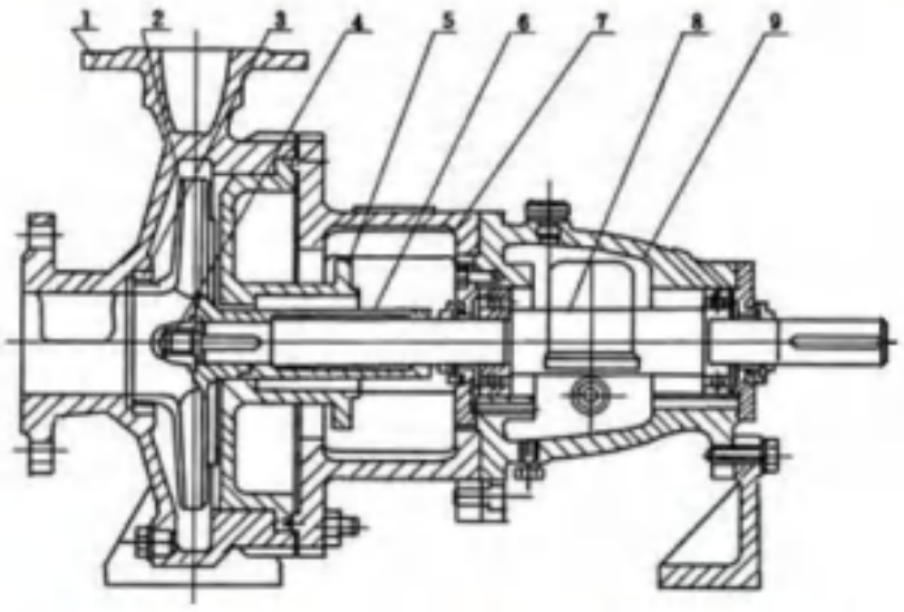

IH化工离心泵产品图

IH不锈钢离心泵结构说明

1. 1H型化工泵主要零部件(见图1)有 1-泵体 2-叶轮 3-密封环 4-叶轮螺母 5-泵盖6-密封部件 7-中间支架8-轴 9-悬架部件等。

2.泵的旋转方向,从驱动端看,按顺时针方向旋转。

3.泵的结构特点(见图)是,泵盖通过止口固定在中间支架上,然后通过泵体与中间支架止口的连接把泵盖夹紧在中间。泵体是轴向吸入,径向排出,脚支承式,可直接固定在底座上。悬架部件通过止口固定在中间支架上,并用悬架支架支撑底座上,为拆卸方便,设计了加长联轴器,检修时可以不拆卸进出口联接管路、泵体和电动机,只需拆下加长联轴器的中间联接件,即可退出转子部件进行检修。这是国际上一种通用的结构形式。

4.泵的密封型式采用填料密封或机械密封,由用户根据需要选用,同时也允许采用适合于ISO-3069规定的密封空腔尺寸和其他结构的轴封形式,如带波纹管的机械密封和副叶轮密封等。

IH不锈钢离心泵结构图及零部件名称

零部件名称:1、泵体 2、叶轮 3、密封环 4、叶轮螺母5、泵盖 6、密封部件 7、中间支架 8、轴 9、悬架部件

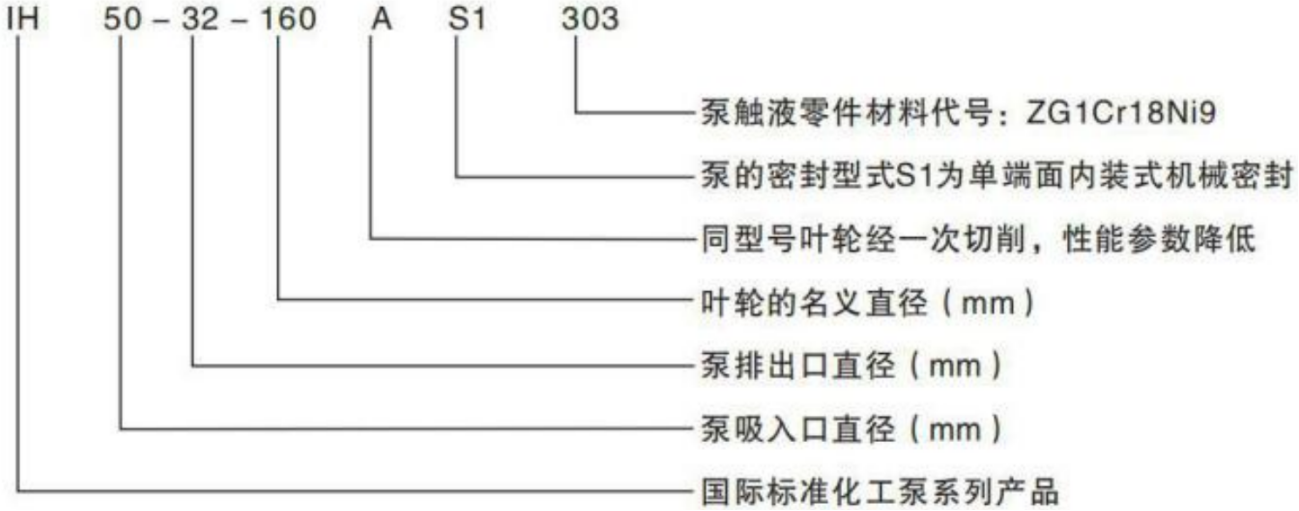

IH不锈钢离心泵型号意义

IH不锈钢离心泵的装配与拆卸

1 泵的拆卸顺序:

1.1拧下泵体上的放液管堵和悬架体上的放油管堵,放净泵内液体及其悬架体内储油室的存油。如有外引液密封管路的也拆下。

1.2拆开泵体与中间支架联结螺栓,将中间支架、悬架部件、密封部件等全部转子组件从泵体中取出(在此之前应先拆出加长联轴器的中间连接件)

1.3 松开叶轮螺母,取出叶轮和键。

1.4 将泵盖连同轴套,机械密封端盖及机械密封等组合件一起从轴上取下。此时应注意勿使轴套与泵盖等相对滑动,然后再把密封端盖拆开,将机械密封连同轴套一起取出,再把轴套和机械密封拆开,如果是软填料密封,可先从泵盖上取下轴套,再顺次拆开填料压盖,填料和填料环等。对结构特殊的机械密封,要注意其不同的拆装方法。

1.5 拆下中间支架和悬架支架。

1.6 拆下泵联轴器和键。

1.7拆下悬架两端的防尘盘和轴承的前后盖,再把轴连轴承一起从悬架中取出。

1.8 拆开轴承和轴。

2 泵的装配

泵的装配顺序基本上可按照拆卸顺序的反向进行,但装配时要注意检查各密封面垫片应完好,并注意切勿漏装垫片和更换不完好的垫片。

IH不锈钢离心泵使用机械密封注意事项

本系列泵可根据使用条件的不同,安装不同形式的机械密封,如内装单端面平衡型和非平衡型,双端面平衡型及非平衡型,外装式机械密封等。因此,根据所选用密封形式的不同其使用方法和注意事项也有所不同,具体情况按照《机械密封安装使用说明书》中的规定去处理。下面仅提几点一般应注意的事项:

6.1 一般机械密封适用于清洁的,无悬浮颗粒的介质中,因此,对新装的管道系统和储液灌,应认真冲洗干净,严防固体杂质进入机械密封端面使密封失效。

6.2 在结晶的介质中,使用机械密封时,要注意经常冲洗。停车后重新起动前,要将机械密封上的结晶清洗干净。

6.3 拆卸机械密封应仔细,不许动用手锥,铁器等敲击,以免破坏静环密封面。

6.4 如果有污垢拆不下来时,不要勉强去拆,应设法清除污垢,冲洗干净后,再进行拆卸,以免损坏密封元件。

6.5 安装机械密封前,应检查所有密封元件是否有失效的损坏的,如有则重新修复或更换新元件。

6.6 应严格检查动环与静环的对磨密封端面,不允许有任何细微的划伤、碰破等缺陷。所有零部件,包括泵体、叶轮、密封腔等在装配前均应冲洗干净。尤其是动静环端面用清洁柔软的布和棉纱认真擦干净,然后涂上一层清洁的油脂或机油。

6.7 装配中要注意消除偏差,紧固螺钉时,避免发生偏斜,使密封失效。

6.8 正确调整弹簧的压缩量,使其不致太紧或太松。太紧,密封端面很快磨损而失效而且消耗功率大;太松则密封不起作用,泄漏量过大。所以泵安装好以后用手盘动,转动效应感觉到密封弹簧有了一定缩量,而又能轻快、灵活的转动,没有咬紧的感觉,如感觉太紧或盘不动,则应适当调松一下。

6.9 对有外部冲洗的机械密封,起动前应开启冲洗液使密封腔内充满密封液。停车时先停泵,后关密封冲洗液。

IH不锈钢离心泵型号及性能参数表

| 泵型号 | 流量Q | 扬程H(m) | 转速η(转/分) | 功率N(千瓦) | 效率 η (%) | 必需汽蚀余量△h(米) | 叶轮直径D(mm) | 重量(公斤) | ||

| (米/时) | (升/秒) | 轴功率 | 电机功率 | |||||||

| IH50-32-125 | 6.3 | 1.74 | 5 | 1450 | 0.19 | 0.55 | 45 | 125 | ||

| IH50-32-160 | 8 | 0.34 | 0.55 | 40 | 2.0 | 160 | ||||

| IH50-32-200 | 12.5 | 0.65 | 1.1 | 33 | 200 | |||||

| IH50-32-250 | 20 | 1.27 | 2.2 | 27 | 250 | |||||

| IH65-50-125 | 12.5 | 3.47 | 5 | 0.31 | 0.55 | 55 | 125 | |||

| IH65-50-160 | 8 | 0.53 | 0.75 | 51 | 160 | |||||

| IH65-40-200 | 12.5 | 0.93 | 1.5 | 46 | 200 | |||||

| IH65-40-250 | 20 | 1.75 | 3 | 39 | 250 | |||||

| IH65-40-315 | 32 | 3.3 | 5.5 | 33 | 315 | |||||

| IH80-65-125 | 25 | 6.94 | 5 | 0.53 | 0.75 | 64 | 2.5 | 125 | ||

| IH80-65-160 | 8 | 0.88 | 1.5 | 62 | 160 | |||||

| IH80-50-200 | 12.5 | 1.49 | 2.2 | 57 | 2 | 200 | ||||

| IH80-50-250 | 20 | 2.569 | 53 | 250 | ||||||

| IH80-50-315 | 32 | 5.067 | 43 | 315 | ||||||

| IH100-80-125 | 50 | 13.9 | 5 | 0.92 | 74 | 125 | ||||

| IH100-80-160 | 8 | 1.58 | 2.2 | 69 | 3.4 | 160 | ||||

| IH100-65-200 | 12.5 | 2.5 | 3 | 69 | 2.5 | 200 | ||||

| IH100-65-250 | 20 | 4.3 | 5.5 | 65 | 2.5 | 250 | ||||

| IH100-65-315 | 32 | 7.5 | 11 | 58 | 2 | 315 | ||||

| IH125-100-200 | 100 | 27.8 | 12.5 | 4.66 | 7.5 | 73 | 2.9 | 200 | ||

| IH125-100-250 | 20 | 7.56 | 11 | 72 | 2.3 | 250 | ||||

| IH125-100-315 | 32 | 12.82 | 68 | 315 | ||||||

| IH125-100-400 | 50 | 22.69 | 60 | 400 | ||||||

| IH150-125-250 | 200 | 55.6 | 20 | 14.1 | 18.5 | 77 | 2.8 | 250 | ||

| IH150-125-315 | 32 | 23.2 | 30 | 75 | 2.8 | 315 | ||||

| IH150-125-400 | 50 | 38.9 | 55 | 70 | 2.5 | 400 | ||||

| IH200-150-250 | 400 | 111.1 | 20 | 26.9 | 81 | 250 | ||||

| IH200-150-315 | 32 | 44.1 | 55 | 79 | 3.5 | 315 | ||||

| IH200-150-400 | 50 | 69.8 | 90 | 78 | 3.5 | 400 | ||||

IH不锈钢离心泵型号及性能参数表2

| 泵型号 | 流量Q | 扬程H(m) | 转速n(转/分) | 功率N(千瓦) | 效率%) | 必需汽蚀余量△h(米) | 叶轮直径D(mm) | 重量(公斤) | ||

| (米³/时) | (升/秒) | 轴功率 | 电机功率 | |||||||

| IH50-32-125 | 12.5 | 3.47 | 20 | 2960 | 1.33 | 2.2 | 51 | 2 | 125 | |

| IH50-32-160 | 32 | 2.37 | 3 | 46 | 2 | 160 | ||||

| IH50-32-200 | 50 | 4.36 | 5.5 | 39 | 2 | 200 | ||||

| IH50-32-250 | 80 | 8.25 | 11 | 33 | 2 | 250 | ||||

| IH65-50-125 | 25 | 6.94 | 20 | 2.2 | 3 | 62 | 125 | |||

| IH65-50-160 | 32 | 3.82 | 5.5 | 57 | 2 | 160 | ||||

| IH65-40-200 | 50 | 6.55 | 11 | 52 | 2.0 | 200 | ||||

| IH65-40-250 | 80 | 11.84 | 15 | 46 | 2 | 250 | ||||

| IH65-40-315 | 125 | 21.8 | 30 | 39 | 2 | 315 | ||||

| IH80-65-125 | 50 | 13.88 | 20 | 3.95 | 5.5 | 69 | 3 | 125 | ||

| IH80-65-160 | 32 | 6.5 | 11 | 67 | 2.3 | 160 | ||||

| IH80-50-200 | 50 | 10.8 | 15 | 63 | 2.5 | 200 | ||||

| IH80-50-250 | 80 | 19.11 | 22 | 57 | 250 | |||||

| IH80-50-315 | 125 | 36.21 | 45 | 47 | 315 | |||||

| IH100-80-125 | 100 | 27.77 | 20 | 7.074 | 11 | 77 | 125 | |||

| IH100-80-160 | 32 | 11.9 | 15 | 73 | 4.3 | 160 | ||||

| IH100-65-200 | 50 | 18.9 | 22 | 72 | 3.9 | 200 | ||||

| IH100-65-250 | 80 | 32.8 | 37 | 68 | 3.6 | 250 | ||||

| IH100-65-315 | 125 | 54.9 | 75 | 62 | 3.2 | 315 | ||||

| IH125-100-200 | 250 | 55.55 | 50 | 35.4 | 45 | 77 | 5 | 200 | ||

| IH125-100-250 | 80 | 58.1 | 75 | 75 | 4.5 | 250 | ||||

| IH125-100-315 | 125 | 97.29 | 70 | 315 | ||||||

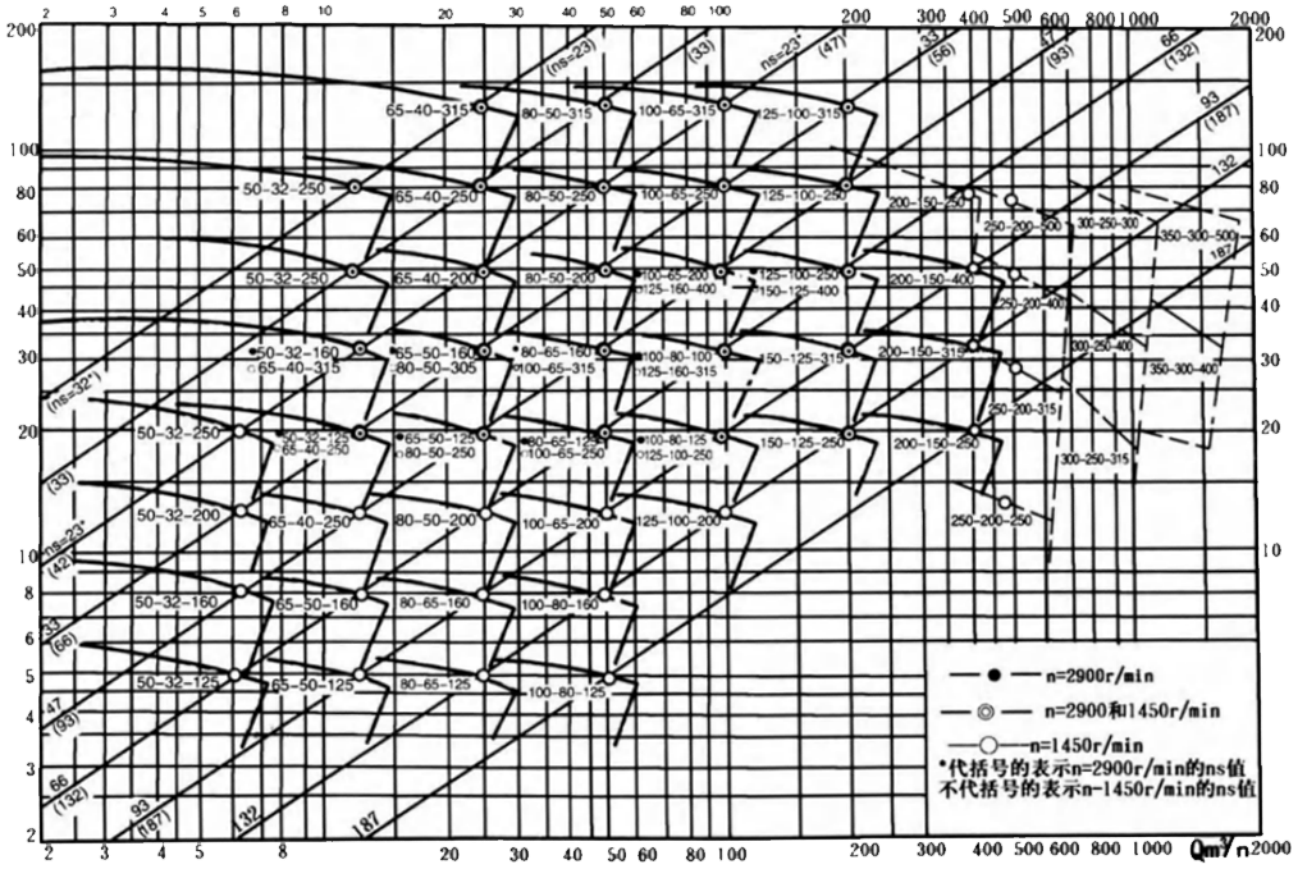

IH不锈钢离心泵型谱图

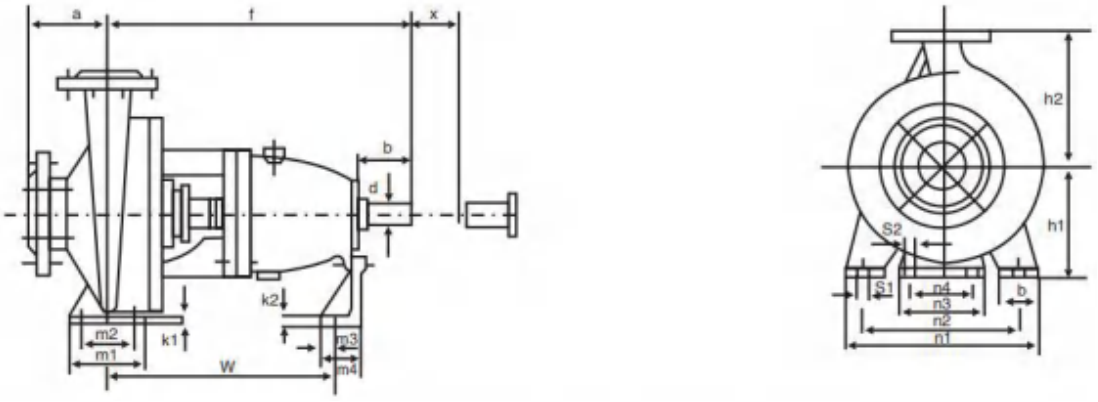

IH不锈钢离心泵泵头及脚座外形尺寸图

IH不锈钢离心泵泵头及脚座外形尺寸表

| 产品型号 | 泵 | 泵 脚 座 | 螺栓孔 | 轴端 | 间隔 | ||||||||||||||||

| a | f | h, | h, | b | m, | m, | m, | m. | n, | n, | n, | n | k, | k. | W | s, | s, | d | L | X | |

| IH50-32-125 | 80 | 385 | 112 | 140 | 50 | 100 | 70 | 19 | 60 | 190 | 140 | 110 | 145 | 12 | 10 | 285 | M12 | M12 | 24 | 50 | 100 |

| IH50-32-160 | 132 | 160 | 240 | 190 | |||||||||||||||||

| IH50-32-200 | 160 | 180 | |||||||||||||||||||

| IH50-32-250 | 100 | 500 | 180 | 225 | 65 | 125 | 95 | 25 | 65 | 320 | 250 | 16 | 14 | 370 | 32 | 80 | |||||

| IH65-32-125 | 80 | 385 | 112 | 140 | 50 | 100 | 70 | 19 | 60 | 210 | 160 | 110 | 145 | 12 | 10 | 285 | M12 | M12 | 24 | 50 | 100 |

| IH65-50-160 | 132 | 160 | 240 | 190 | |||||||||||||||||

| IH65-40-200 | 100 | 160 | 180 | 265 | 312 | ||||||||||||||||

| IH65-40-250 | 500 | 180 | 225 | 65 | 125 | 95 | 25 | 65 | 320 | 250 | 16 | 14 | 370 | 32 | 80 | ||||||

| IH65-40-315 | 125 | 200 | 250 | 345 | 280 | ||||||||||||||||

| IH80-65-125 | 100 | 385 | 132 | 160 | 50 | 100 | 70 | 19 | 60 | 240 | 190 | 110 | 145 | 12 | 10 | 285 | M12 | M12 | 24 | 50 | 100 |

| IH80-65-160 | 160 | 180 | 265 | 212 | |||||||||||||||||

| IH80-50-200 | 200 | ||||||||||||||||||||

| IH80-50-250 | 125 | 500 | 180 | 225 | 65 | 125 | 95 | 25 | 65 | 320 | 250 | 16 | 14 | 370 | 32 | 80 | |||||

| IH80-50-315 | 225 | 280 | 345 | 280 | |||||||||||||||||

| IH100-80-125 | 100 | 385 | 160 | 180 | 65 | 25 | 95 | 19 | 60 | 280 | 212 | 110 | 145 | 12 | 10 | 285 | M12 | M12 | 24 | 50 | 100 |

| IH100-80-160 | 500 | 200 | 24 | 16 | 370 | 32 | 80 | ||||||||||||||

| IH100-65-200 | 180 | 225 | 25 | 65 | 320 | 250 | 14 | M16 | 140 | ||||||||||||

| IH100-65-250 | 125 | 200 | 250 | 80 | 160 | 120 | 360 | 280 | |||||||||||||

| IH100-65-315 | 530 | 225 | 280 | 28 | 400 | 315 | |||||||||||||||

| IH125-100-200 | 125 | 500 | 200 | 280 | 80 | 160 | 120 | 25 | 65 | 360 | 280 | 110 | 145 | 16 | 14 | 370 | M16 | M12 | 42 | 80 | 140 |

| IH125-100-250 | 140 | 530| | 225 | 28 | 400 | 315 | 20 | 42 | 110 | ||||||||||||

| IH125-100-315 | 250 | 315 | |||||||||||||||||||

| IH125-100-400 | 280 | 355 | 500 | 400 | M20 | ||||||||||||||||

| IH150-125-250 | 140 | 530| | 250 | 355 | 80 | 160 | 120 | 28 | 65 | 400 | 315 | 110 | 145 | 20 | 14 | 370 | M16M20 | M12 | 42 | 110 | 140 |

| IH150-125-315 | 280 | 100 | 200 | 150 | 500 | 400 | |||||||||||||||

| IH150-150-400 | 315 | 400 | |||||||||||||||||||

| IH200-150-250 | 160 | 530| | 280 | 275 | 100 | 200 | 150 | 28 | 65 | 500 | 400 | 110 | 145 | 20 | 14 | 370 | M20 | M12 | 42 | 110 | 180 |

| IH200-150-315 | 650 | 315 | 400 | 38 | 80 | 550 | 450 | 110 | 200 | 30 | 500 | M20 | M16 | 48 | |||||||

| IH200-150-400 | 450 | ||||||||||||||||||||

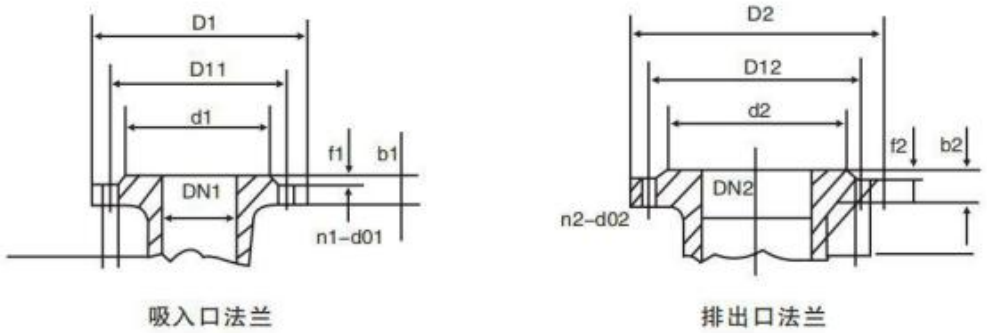

IH不锈钢离心泵进出口法兰尺寸图

IH不锈钢离心泵进出口法兰尺寸表

| 产品型号 | 吸 入 口 法 兰 | 排 出 口 法兰 | ||||||||||||

| DN, | D, | D,. | d, | b, | f, | n,-d。 | DN, | D. | D₁ | d₃ | b₂ | f₂ | n₂-d。 | |

| IH50-32-125 | 50 | 165 | 125 | 99 | 20 | 3 | 4-17.5 | 32 | 140 | 100 | 76 | 18 | 2 | 4-17.5 |

| IH50-32-160 | ||||||||||||||

| IH50-32-200 | ||||||||||||||

| IH50-32-250 | ||||||||||||||

| IH65-50-125 | 65 | 185 | 145 | 118 | 50 | 165 | 125 | 99 | 20 | 3 | ||||

| IH65-50-160 | ||||||||||||||

| IH65-40-200 | 40 | 150 | 110 | 84 | 18 | |||||||||

| IH65-40-250 | ||||||||||||||

| IH65-40-315 | ||||||||||||||

| IH80-65-125 | 80 | 200 | 160 | 132 | 8-17.5 | 65 | 185 | 145 | 118 | 20 | ||||

| IH80-65-160 | ||||||||||||||

| IH80-50-200 | 50 | 165 | 125 | 99 | ||||||||||

| IH80-50-250 | ||||||||||||||

| IH80-50-315 | ||||||||||||||

| IH100-80-125 | 100 | 220 | 180 | 156 | 22 | 80 | 200 | 160 | 132 | 8-17.5 | ||||

| IH100-80-160 | ||||||||||||||

| IH100-65-200 | 65 | 185 | 145 | 118 | 4-17.5 | |||||||||

| IH100-32-315 | ||||||||||||||

| IH100-65-315 | ||||||||||||||

| IH125-100-200 | 125 | 250 | 210 | 184 | 100 | 220 | 180 | 156 | 22 | 8-17.5 | ||||

| IH125-100-250 | ||||||||||||||

| IH125-100-315 | ||||||||||||||

| IH125-100-400 | ||||||||||||||

| IH150-125-250 | 150 | 285 | 240 | 211 | 24 | 8-22 | 125 | 250 | 210 | 184 | ||||

| IH150-125-315 | ||||||||||||||

| IH150-125-400 | ||||||||||||||

| IH200-150-250 | 200 | 340 | 295 | 266 | 150 | 285 | 240 | 211 | 24 | |||||

| IH200-150-315 | ||||||||||||||

| IH200-150-400 | ||||||||||||||

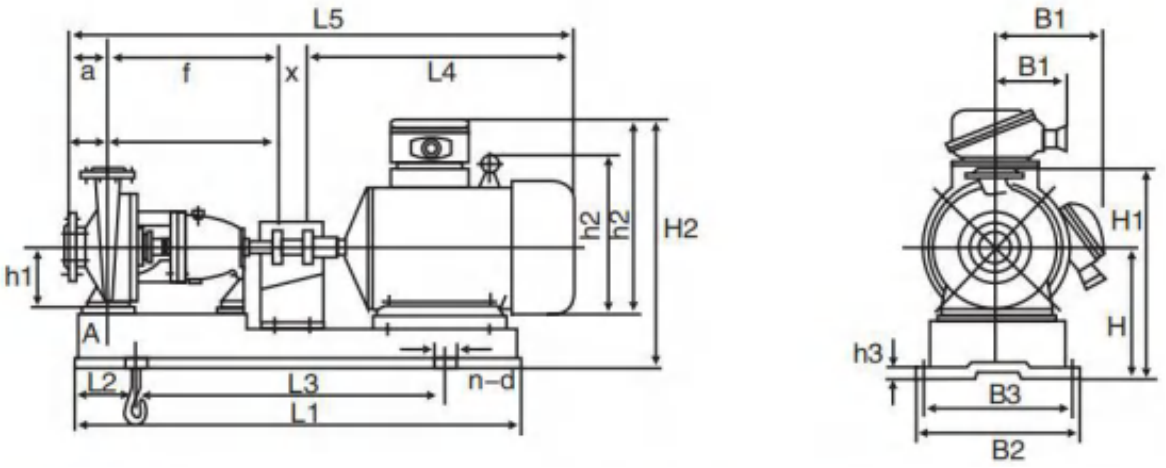

IH不锈钢离心泵外形安装尺寸图

IH不锈钢离心泵外形安装尺寸表

| 产品型号 | 电机型号功率(Kw) | 外 型 及 安 装 尺 寸 | 机组 重量(Kg) | ||||||||||||||||||

| A | L, | L₂ | L, | L₄ | a | f | X | L | B,/B₂ | B₂ | B, | h, | h/h, | h, | H | H, | H₂ | n-d | |||

| H50-32-125 | YB801-40.55 | 80 | 820 | 150 | 540 | 330 | 80 | 385 | 00 | 895 | 150225 | 360 | 320 | 112 | 170325 | 25 | 237 | 377 | 482 | 4-φ185 | |

| YB802-2/1.1 | |||||||||||||||||||||

| YB90S-2/1.5 | 360 | 925 | 155225 | 190340 | 487 | ||||||||||||||||

| YB90L-222 | 920 | 170 | 600 | 385 | 950 | 390 | 350 | 30 | |||||||||||||

| YB100L-23.0 | 430 | 995 | 180225 | 245370 | 507 | 4-φ185 | |||||||||||||||

| IH50-32-160 | YB801-4/0.55 | 80 | 820 | 150 | 540 | 330 | 80 | 385 | 100 | 895 | 15025 | 360 | 320 | 132 | 170325 | 25 | 257 | 417 | 502 | 4-φ24 | |

| YB802-4/0.75 | |||||||||||||||||||||

| YB90S-4/1.1 | 360 | 925 | 155225 | 190340 | 507 | ||||||||||||||||

| YB90L-222 | 920 | 170 | 600 | 385 | 950 | 390 | 350 | 30 | |||||||||||||

| YB100L-23.0 | 430 | 995 | 180225 | 245370 | 522 | ||||||||||||||||

| YB112M-2/4.0 | 460 | 1025 | 190225 | 265385 | 530 | ||||||||||||||||

| YB132S1-25.5 | 1020 | 190 | 660 | 510 | 1070 | 210240 | 450 | 400 | 315430 | 555 | 4-φ185 | ||||||||||

| IH50-32-200 | YB801-4/0.55 | 80 | 820 | 150 | 540 | 330 | 80 | 385 | 100 | 896 | 150225 | 360 | 320 | 160 | 170325 | 25 | 285 | 465 | 530 | 4-φ24 | |

| YB802-4/0.75 | |||||||||||||||||||||

| YB90S-4/1.1 | 360 | 925 | 55255 | 90340 | 535 | ||||||||||||||||

| YB90L-4/15 | 920 | 170 | 600 | 385 | 950 | 390 | 350 | 30 | |||||||||||||

| YB112M-5/4.0 | 460 | 1025 | 190225 | 265385 | 558 | ||||||||||||||||

| YB132S-25.5 | 1020 | 190 | 660 | 510 | 075 | 210240 | 450 | 400 | 315430 | 583 | |||||||||||

| YB132S-27.5 | |||||||||||||||||||||

| YB160M-2/11 | 1140 | 210 | 740 | 665 | 1220 | 255240 | 490 | 440 | 385485 | 300 | 480 | 625 | |||||||||

| IH50-32-250 | YB90S-4/1.1 | 95 | 020 | 190 | 660 | 360 | 100 | 500 | 100 | 060 | 155225 | 450 | 400 | 180 | 190340 | 30 | 305 | 530 | 565 | 4-φ24 | |

| YB9OL-4/15 | 385 | 085 | |||||||||||||||||||

| YB100L1-4/22 | 430 | 130 | 180255 | 245370 | 575 | ||||||||||||||||

| YB100L1-43.0 | |||||||||||||||||||||

| YB132S2-27.5 | 140 | 210 | 740 | 510 | 1210 | 210240 | 490 | 440 | 315430 | 320 | 545 | 618 | |||||||||

| YB160M1-2/11 | 1270 | 225 | 840 | 655 | 355 | 255240 | 540 | 490 | 385485 | 340 | 565 | 665 | |||||||||

| YB160M2-2/15 | |||||||||||||||||||||

| YB160L-2/18.5 | 695 | 1395 | |||||||||||||||||||

| YB180M-222 | 730 | 1430 | 285240 | 430525 | 685 | ||||||||||||||||

IH不锈钢离心泵外形安装尺寸表2

| 产品型号 | 电机型号功率(Kw) | 外 型 及 安 装 尺 寸 | 机组重量(Kg) | ||||||||||||||||||

| A | L, | L₂ | L, | L. | a | f | X | L | B,/B₂ | B₂ | B, | h, | h,/h, | h, | H | H, | H₂ | n-d | |||

| IH65-50-125 | YB801-4055 | 80 | 820 | 150 | 540 | 330 | 80 | 385 | 100 | 895 | 150225 | 360 | 320 | 112 | 170325 | 25 | 237 | 377 | 482 | ||

| YB802-40.75 | |||||||||||||||||||||

| YB90L-2/22 | 920 | 170 | 600 | 385 | 950 | 155225 | 390 | 350 | 190340 | 30 | 487 | 4-φ185 | |||||||||

| YB100L-230 | 430 | 995 | 180225 | 245370 | 507 | ||||||||||||||||

| YB112M-24.0 | 460 | 025 | 190225 | 265385 | 510 | ||||||||||||||||

| YB132S,-25.5 | 020 | 190 | 660 | 510 | 1075 | 210240 | 450 | 400 | 315430 | 535 | 4-φ24 | ||||||||||

| IH65-50-160 | YB801-4055 | 80 | 820 | 150 | 540 | 330 | 80 | 385 | 100 | 895 | 150225 | 360 | 320 | 132 | 170325 | 25 | 257 | 417 | 502 | 4-φ185 | |

| YB802-40.75 | |||||||||||||||||||||

| YB90S-4/1.1 | 360 | 925 | 155/25 | 190340 | 507 | ||||||||||||||||

| YB90L-4/1.5 | 920 | 170 | 600 | 385 | 950 | 390 | 350 | 30 | |||||||||||||

| YB100L-230 | 430 | 995 | 180225 | 245370 | 527 | ||||||||||||||||

| YB112M-2/4.0 | 460 | 1025 | 190225 | 265385 | 530 | ||||||||||||||||

| YB132S,-25.5 | 020 | 190 | 660 | 510 | 075 | 210240 | 450 | 440 | 315430 | 555 | 4-φ24 | ||||||||||

| YB132S-2/75 | |||||||||||||||||||||

| YB160M-2/11 | 1140 | 210 | 740 | 655 | 1220 | 255240 | 490 | 400 | 385485 | 272 | |432 | 597 | |||||||||

| IH65-40-200 | YB802-40.75 | 80 | 920 | 170 | 600 | 330 | 100 | 385 | 100 | 915 | 150225 | 390 | 350 | 60 | 170325 | 30 | 285 | 465 | 530 | 4-φ185 | |

| YB90S-4/1.1 | 360 | 945 | 150225 | 190340 | 535 | ||||||||||||||||

| YB9OL-4/1.5 | 385 | 970 | |||||||||||||||||||

| YB100L,-422 | 430 | 1015 | 180225 | 245370 | 555 | ||||||||||||||||

| YB132S,-25.5 | 020 | 190 | 660 | 510 | 095 | 210240 | 450 | 400 | 315430 | 583 | 4-φ24 | ||||||||||

| YB132S,-25.5 | |||||||||||||||||||||

| YB160M,-2/11 | 140 | 210 | 740 | 665 | 240 | 255240 | 490 | 440 | 385485 | 300 | 480 | 625 | |||||||||

| YB160M,-2/15 | |||||||||||||||||||||

| IH66-40-250 | YB90S-4/1.1 | 95 | 020 | 190 | 660 | 360 | 10 | 500 | 100 | 10601080 | 155255 | 450 | 400 | 180 | 190430 | 30 | 305 | 530 | 555 | 4-φ24 | |

| YB90L-4/1.5 | 385 | ||||||||||||||||||||

| YB100L-422 | 430 | 130 | |180225 | 245370 | 575 | ||||||||||||||||

| YB100L-43.0 | |||||||||||||||||||||

| YB112M-4/4.0 | 460 | 1160 | 190225 | 265385 | 578 | ||||||||||||||||

| YB160M,-2/11 | 270 | 225 | 840 | 655 | 1355 | 255240 | 540 | 490 | 385485 | 340 | 565 | 665 | |||||||||

| YB160M-2-15 | |||||||||||||||||||||

| YB160L-2-18.5 | 695 | 1395 | |||||||||||||||||||

| YB180M-2-22 | 730 | 430 | 280240 | 430525 | 685 | ||||||||||||||||

| YB200L-230 | 420 | 250 | 940 | 803 | 530 | 310290 | 610 | 550 | 475590 | 40 | 360 | |585 | 750 | 4-φ28 | |||||||

| IH65-40-315 | YB100L,-43.0 | 95 | 140 | 210 | 740 | 430 | 125 | 500 | 100 | 155 | 180225 | 490 | 440 | 200 | 245705 | 30 | 340 | 590 | 610 | 4-φ24 | |

| YB112M-4/4.0 | 460 | 185 | 190225 | 265385 | 613 | ||||||||||||||||

| YB132S 455 | 510 | 12351275 | 210240 | 315430 | 638 | ||||||||||||||||

| YB132M-4/7.5 | 550 | ||||||||||||||||||||

| YB160M-4/11 | 1270 | 225 | 840 | 655 | 380 | 255240 | 540 | 490 | 385486 | 360 | 610 | 685 | |||||||||

| YB160M,-2/15 | |||||||||||||||||||||

| YB160L-2/18.5 | 695 | 420 | |||||||||||||||||||

| YB180M-222 | 730 | 1455 | 285240 | 430525 | 705 | ||||||||||||||||

| YB200L-230 | 420 | 250 | 940 | 803840 | 528 | 310290 | 610 | 550 | 475590 | 40 | 380 | 630 | 770 | 4-φ28 | |||||||

| YB200L,-237 | |||||||||||||||||||||

| YB225M-2/45 | 565 | 345290 | 530615 | ||||||||||||||||||

IH不锈钢离心泵外形安装尺寸表3

| 产品型号 | 电机型号功率(Kw) | 外 型 及 安 装 尺 寸 | 机组重量(Kg) | ||||||||||||||||||

| A | L, | L₂ | L₃ | L₄ | a | f | X | L₅ | B/B₂ | B₂ | B, | h₁ | h,/h₂ | h, | H | H, | H₂ | n-d | |||

| IH80-65-125 | YB801-4/0.55 | 80 | 820 | 150 | 540 | 330 | 100 | 385 | 100 | 915 | 150/225 | 360 | 320 | 132 | 170/325 | 25 | 257 | 417 | 502 | 4-φ18.5 | |

| YB802-4/0.75 | |||||||||||||||||||||

| YB90S-4/1.1 | 360 | 945 | 155/225 | 190/340 | 507 | ||||||||||||||||

| YB90L-4/1.5 | 920 | 170 | 600 | 385 | 970 | 390 | 350 | 30 | 527 | ||||||||||||

| YB100L-2/3.0 | 430460 | 015 | 180/225 | 245/370 | 530 | ||||||||||||||||

| YB112M-2/4.0 | 1045 | 190/225 | 265/385 | 555 | |||||||||||||||||

| YB132S,-2/5.5 | 020 | 190 | 660 | 510 | 1095 | 210/240 | 450 | 400 | 315/430 | 597 | 4-φ24 | ||||||||||

| YB132S-2/7.5 | |||||||||||||||||||||

| YB160M,-2/11 | 140 | 210 | 740 | 655 | 1240 | 255/240 | 490 | 440 | 385/485 | 372 | 432 | 530 | |||||||||

| IH80-65-160 | YB802-4/0.75 | 80 | 920 | 170 | 600 | 330360385 | 100 | 385 | 100 | 915| | 150/225 | 390 | 350 | 160 | 170/325 | 30 | 285 | 465 | 4-φ18.5 | ||

| YB90S-4/1.1 | 945 | 155/225 | 90/340 | 535 | |||||||||||||||||

| YB90L-4/1.5 | 970 | ||||||||||||||||||||

| YB100L,-4/3.2 | 430 | 1015 | 180/225 | 245/370 | 555 | ||||||||||||||||

| YB132S,-2/5.5 | 020 | 190 | 660 | 510 | 1095 | 210/240 | 450 | 400 | 315/43Q | 583 | 4-φ24| | ||||||||||

| YB132S-2/7.5 | |||||||||||||||||||||

| YB160M,-2/11 | 140 | 210 | 740 | 655 | 1240 | 255/240 | 490 | 440 | 385/485 | 300 | 480 | 625 | |||||||||

| YB160M-2/15 | |||||||||||||||||||||

| IH80-50-200 | YB90S-4/1.1 | 80 | 920 | 170 | 600 | 360385430 | 100 | 385 | 100 | 945 | 155/225 | 390 | 350 | 160 | 190/340 | 30 | 285 | 485 | 535 | 4-φ18.5 | |

| YB90L-4/1.5 | 970 | ||||||||||||||||||||

| YB100L,-4/2.2 | 1015 | 180/225 | 245/370 | 555 | |||||||||||||||||

| YB100L-4/3.0 | |||||||||||||||||||||

| YB112M-4/4.0 | 460 | 1045 | 190/225 | 265/385 | 558 | ||||||||||||||||

| YB132S,-2/7.5 | 020 | 190 | 660 | 510 | 1095 | 210/240 | 450 | |400 | 315/430 | 583 | 4-φ24 | ||||||||||

| YB160M-2/11 | 140 | 210 | 740 | 655 | 1240 | 255/240 | 490 | 440 | 385/485 | 300 | 500 | 625 | |||||||||

| YB160M,-2/15 | |||||||||||||||||||||

| YB160L-2/18.5 | 695730 | 1280 | |||||||||||||||||||

| YB180M-2/22 | 1315 | 285/240 | 430/525 | 645 | |||||||||||||||||

| IH80-50-250 | YB100L,-4/2.2 | 95 | 020 | 190 | 660 | 430[460 | 125 | 500 | 100 | 1155 | 180/225 | 450 | |400 | 180 | 245/370 | 30 | 305 | 530 | 575 | 4-φ24 | |

| YB100L-4/3.0 | |||||||||||||||||||||

| YB112M-4/4.0 | 1185 | 190/225 | 265/385 | 578 | |||||||||||||||||

| YB132S-4/5.5 | 140 | 210 | 740 | 510550 | 12351275 | 210/240 | 490 | |440 | 315/430 | 320 | 545 | 618 | |||||||||

| YB132M-4/7.5 | |||||||||||||||||||||

| YB160M-2/15 | 270 | 225 | 840 | 655 | 1380 | 255/240 | 540 | |490 | 385/485 | 340 | 565 | 665 | |||||||||

| YB160L-2/18.5 | 695 | 1420 | |||||||||||||||||||

| YB180M-2/22 | 730 | 1455 | 285/240 | 430/525 | 685 | ||||||||||||||||

| YB200L,-2/30 | 420 | 250 | 940 | 803840 | 1582 | 310/290 | 610 | 550 | 475/590 | 40 | 360 | 685 | 750 | 4-024 | |||||||

| YB200L-2/37 | |||||||||||||||||||||

| YB225M-2/45 | 1565 | 345/290 | 530/615 | 638 | |||||||||||||||||

| IH80-50-315 | YB112M-4/4.0 | 95 | 140 | 210 | 740 | 460510 | 125 | 500 | 100 | 1185 | 190/225 | 490 | 440 | 225 | 265/385 | 30 | 365 | 645 | 663 | 4-φ24 | |

| YB132S-4/5.5 | 12351275 | 210/240 | 315/430 | ||||||||||||||||||

| YB132M-4/7.5 | 550 | ||||||||||||||||||||

| YB160M-4/11 | 270 | 225 | 840 | 655695 | 13801420 | 255/240 | 540 | |490 | 385/485 | 385 | 665 | 710 | |||||||||

| YB160L-4/15 | |||||||||||||||||||||

| YB200L-2/30 | 420 | 250 | 940 | 803 | 1528 | 310/290 | 610 | 550 | 475/590 | 40 | 405 | 385 | 795 | 4-φ28 | |||||||

| YB200L,-3/37 | |||||||||||||||||||||

| YB225M-2/45 | 840 | 1565 | 345/290 | 530/615 | |||||||||||||||||

| YB220M-2/55 | 620 | 290 | i060 | 935 | 660 | 385/330 | 660 | 600 | 575/740 | 425 | 705 | 915 | |||||||||

| YB280S-2/75 | 820 | 320 | 1200 | h010 | 1735 | 410/330 | 730 | 670 | 640/800 | 945 | |||||||||||

IH不锈钢离心泵外形安装尺寸表4

| 产品型号 | 电机型号功率(Kw) | 外 型 及 安 装 尺 寸 | 机组 重量 (Kg) | ||||||||||||||||||

| A | L, | L, | L, | L. | a | f | X | L, | B,/B₂ | B₂ | B, | h, | h,/h, | h, | H | H, | H₂ | n-d | |||

| IH100-80-125 | YB802-4/0.75 | 95 | 920 | 170 | 600 | 330 | 100 | 385 | 100 | 915 | 150/225 | 390 | 350 | 160 160 180 | 170/325 | 30 | 285 | 465 | 530 | ||

| YB90S-4/1.1 | 360 | 945 | 155/225 | 190/340 | 535 | ||||||||||||||||

| YB90L-4-1.5 | 385 | 970 | |||||||||||||||||||

| YB100L1-4/2.2 | 430 | 1015 | 180/225 | 245/370 | 555 | 4-φ18.5 | |||||||||||||||

| YB100L2-4/3.0 | |||||||||||||||||||||

| YB112M-4/4.0 | 460 | 1045 | 190/225 | 265/385 | 558 | ||||||||||||||||

| YB132S1-2/5.5 | 1020 | 190 | 660 | 510 | 1095 | 210/240 | 450 | 400 | 315/430 | 583 | 4-φ24 | ||||||||||

| YB132S2-2/7.5 | |||||||||||||||||||||

| YB160M1-2/11 | 140 | 210 | 740 | 655 | 240 | 255/240 | 490 | 440 | 385/485 | 300 | 480 | 625 | |||||||||

| YB160M2-2/15 | |||||||||||||||||||||

| IH100-80-160 | YB90L-4/1.5 | |95| | 1020 | 190 | 660 | 385 | 100 | 500 | 100 | 1085 | 155/225 | 450 | 400 | 200 | 190/340 | 30 | 285 | 485 | 535 | 4-φ24 | |

| YB100L1-4/2.2 | 430 | 130 | 180/225 | 245/370 | 555 | ||||||||||||||||

| YB100L2-4/3.0 | |||||||||||||||||||||

| YB112M-4/4.0 | 460 | 1160 | 190/225 | 265/385 | 558 | ||||||||||||||||

| YB132S2-2/7.5 | 1140 | 210 | 740 | 510 | 210 | 210/240 | 490 | 440 | 315/430 | 300 | 500 | 598 | |||||||||

| YB160M1-2/11 | 1270 | 225 | 840 | 655 | 1355 | 255/240 | 540 | 490 | 385/485 | 320 | 520 | 640 | |||||||||

| YB160M2-2/15 | |||||||||||||||||||||

| YB160L-2/18.5 | 695 | 1395 | |||||||||||||||||||

| YB180M-2/22 | 730 | 1430 | 285/240 | 430/525 | 665 | ||||||||||||||||

| YB200L-4/30 | 1420 | 250 | 940 | 803 | 1503 | 310/290 | 610 | |550 | 475/590 | 40 | 340 | 540 | 730 | 4-φ28 | |||||||

| IH100-65-200 | YB100L1-4/2.2 | 95 | 1140 | 210 | 740 | 430 | 100 | 500 | 140 | 170 | 180/225 | 490 | 440 | 245/370 | 30 | 320 | 545 | 590 | 4-φ24 | ||

| YB100L2-4/3.0 | |||||||||||||||||||||

| YB112M-4/4.0 | 460 | 1200 | 190/225 | 265/385 | 593 | ||||||||||||||||

| YB132S-4/5.5 | 510 | 1250 | 210/240 | 315/430 | 618 | ||||||||||||||||

| YB132M-4/7.5 | 550 | 1290 | |||||||||||||||||||

| YB160M2-2/15 | 1270 | 225 | 840 | 655 | 1395 | 255/240 | 540 | 490 | 385/485 | 340 | 565 | 665 | |||||||||

| YB160L-2/18.5 | 695 | 1435 | |||||||||||||||||||

| YB180M-2/22 | 730 | 1470 | 285/240 | 430/525 | 685 | ||||||||||||||||

| YB200L1-2/30 | 420 | 250 | 940 | 803840 | 543 | 310/290 | 610 | 550 | 475/590 | 40 | 360 | 585 | 750 | 4-φ28 | |||||||

| YB200L2-2/37 | |||||||||||||||||||||

| YB225M-2/45 | 1580 | 345/290 | 530/815 | ||||||||||||||||||

| IH100-65-250 | YB100L2-4/3.0 | 110 | 1140 | 210 | 740 | 430 | 125 | 500 | 140 | 1195 | 180/225 | 490 | 440 | 245/370 | 30 | 340 | 590 | 610 | 4-φ24 | ||

| YB112M-4/4.0 | 460 | 1225 | 190/225 | 265/385 | 613 | ||||||||||||||||

| YB132S-4/5.5 | 510 | 1275 | 210/240 | 315/480 | 638 | ||||||||||||||||

| YB132M-4/7.5 | 550 | 1315 | |||||||||||||||||||

| YB160M-4/11 | 270 | 225 | 840 | 655 | 1420 | 255/240 | 540 | 490 | 385/485 | 360 | 610 | 685 | |||||||||

| YB160L-4/15 | 695 | 1460 | |||||||||||||||||||

| YB180M-2/22 | 730 | 1495 | 285/240 | 430/525 | 766 | ||||||||||||||||

| YB200L-2/30 | 1420 | 250 | 940 | 803 | 1570 | 310/290 | 610 | |550 | 475/290 | 380 | 630 | 776 | 4-φ28 | ||||||||

| YB200L2-2/37 | |||||||||||||||||||||

| YB225M-2/45 | 870 | 1635 | 345/290 | 530/615 | 790 | ||||||||||||||||

| YB250M-2/55 | 1620 | 290 | 060 | 935 | 1700 | 385/290 | 660 | 600 | 575/740 | 400 | 650 | 890 | |||||||||

| YB280S-2/75 | 1820 | 320 | 1200 | 1010 | 1776 | 410/330 | 730 | 670 | 640/800 | 920 | |||||||||||

IH不锈钢离心泵外形安装尺寸表5

| 产品型号 | 电机型号功率(Kw) | 外 型 及 安 装 尺 寸 | 机组 重量 (Kg) | ||||||||||||||||||

| A | L, | L, | L, | L. | a | f | X | L | B,/B, | B, | B, | h, | h/h₂ | h, | H | H, | H, | n-d | |||

| IH100-65-315 | YB132S-4/5.5 | h10 | 1270 | 225 | 840 | 510 | 125 | 530 | 140 | 1305 | 210/240 | 540 | 490 | 225 | 315/430 | 30 | 385 | 665 | 683 | 4-φ24 | |

| Y8132M-4/7.5 | 550 | 1345 | |||||||||||||||||||

| YB160M-4/11 | 655 | 1450 | 255/240 | 385/485 | 710 | ||||||||||||||||

| YB160L-4/15 | 420 | 250 | 940 | 695 | 1490 | 610 | 550 | 40 | 405 | 685 | 4-φ28 | ||||||||||

| YB180M-4/18.5 | 730 | 1525 | 285/240 | 430/525 | 750 | ||||||||||||||||

| YB200L2-2/37 | 310/290 | 475/590 | 795 | ||||||||||||||||||

| YB225M-2/45 | 620 | 290 | |1060 | 870 | 1665 | 345/290 | 660 | 600 | 530/615 | 425 | 705 | 815 | |||||||||

| YB250M-2/55 | 935 | 1730 | 385/330 | 575/740 | 915 | ||||||||||||||||

| YB280S-2/75 | 820 | 320 | 1200 | 1010 | 1805 | 410/330 | 730 | 670 | 640/800 | 945 | |||||||||||

| YB280M-2/90 | 1060 | 1855 | |||||||||||||||||||

| IH125-100-200 | YB112M-4/4.0 | 110 | 1140 | 210 | 740 | 460 | 125 | 500 | 140 | 1225 | 190/225 | 490 | 440 | 200 | 265/385 | 30 | 340 | 620 | 613 | 4-φ24 | |

| YB132S-4/5.5 | 510 | 1275 | 210/240 | 315/430 | 638 | ||||||||||||||||

| YB132M-4/7.5 | 550 | 1315 | |||||||||||||||||||

| YB160M-4/11 | 1270 | 225 | 810 | 655 | 1420 | 255/240 | 540 | 490 | 385/485 | 360 | 640 | 685 | |||||||||

| YB200L1-2/30 | 1420 | 250 | |940 | 803 | 1568 | 310/290 | 610 | 550 | 475/590 | |40 | 380 | 660 | 770 | 4-φ28 | |||||||

| YB200L2-2/37 | |||||||||||||||||||||

| YB225M-2/45 | 840 | 1605 | 345/290 | 530/615 | |||||||||||||||||

| YB250M-2/55 | 620 | 290 | |1060 | 935 | 1700 | 385/330 | 660 | 600 | 575/740 | 400 | 680 | 890 | |||||||||

| YB280-2/75 | 820 | 320 | 1200 | 1010 | 1775 | 410/330 | 730 | 670 | 640/800 | 920 | |||||||||||

| IH125-100-250 | YB132S-4/5.5 | 110 | 270 | 225 | 840| | 510 | 140 | 530 | 140 | 1320 | 210/240 | 540 | 490 | 225 | 315/430 | 30 | 385 | 545 | 683 | 4-φ24 | |

| YB132M-4/7.5 | 550 | 13660 | |||||||||||||||||||

| YB160M-4/11 | 655 | 1460 | 255/240 | 710 | |||||||||||||||||

| YB160L-4/15 | 1420 | 250 | 940 | 695 | 1505 | 610 | 550 | 385/485 | 40 | 405 | 685 | 730 | 4-φ28 | ||||||||

| YB180M-4/18.5 | 730 | 1540 | 285/240 | 430/525 | 750 | ||||||||||||||||

| YB225M-2/45 | 620 | 290 | 1060 | 840 | 1650 | 345/290 | 660 | 600 | 530/615 | 425 | 705 | 815 | |||||||||

| YB250M-2/55 | 935 | 1745 | 385/330 | 575/740 | 915 | ||||||||||||||||

| YB280S-2/75 | 820 | 320 | |1200 | 1010 | 1820 | 410/330 | 730 | 670 | 640/800 | 945 | |||||||||||

| YB280M-2/90 | 1060 | 1870 | |||||||||||||||||||

| IH125-100-315 | YB160M-4/1.1 | 110 | 1270 | 225 | 840 | 655 | 140 | 530 | 140 | 1465 | 255/240 | 540 | 490 | 250 | 385/485 | 30 | 410 | 725 | 735 | 4-φ24 | |

| YB160L-4/15 | 1420 | 250 | 940 | 695 | 1505 | 610 | 550 | 40 | 430 | 745 | 755 | 4-φ28 | |||||||||

| YB180M-4/18.5 | 730 | 1540 | 285/240 | 430/525 | 775 | ||||||||||||||||

| YB180L-4/22 | 750 | 1560 | |||||||||||||||||||

| YB200L-4/30 | 803 | 1613 | 310/290 | 475/590 | 820 | ||||||||||||||||

| Y8225S-4/37 | 845 | 1655 | 345/290 | 530/615 | |||||||||||||||||

| YB280S-2/75 | 1820 | 320 | 1200 | 10101060 | 1820 | 410/330 | 730 | 670 | 640/800 | 450 | 765 | 970 | |||||||||

| YB280M-2/90 | 1870 | ||||||||||||||||||||

| IH125-100-400 | YB160L-4/15 | 130 | 1620 | 290 | 1060 | 695 | 140 | 530 | 140 | 1505 | 225/240 | 660 | 600 | 280 | 385/485 | 40 | 480 | 835 | 805 | 4-φ28 | |

| YB180M-4/18.5 | 730 | 1540 | 285/240 | 430/525 | 825 | ||||||||||||||||

| YB180L-4/22 | 750 | 1560 | |||||||||||||||||||

| YB200L-4/30 | 803 | 1613 | 310/290 | 475/590 | 870 | ||||||||||||||||

| YB225S-4/37 | 845 | 1655 | 345/290 | 530/615 | |||||||||||||||||

| YB225M-4/45 | 870935 | 1680 | |||||||||||||||||||

| YB250M-4/55 | 1745 | 385/330 | 575/740 | 970 | |||||||||||||||||

IH不锈钢离心泵外形安装尺寸表6

| 产品型号 | 电机型号功率(Kw) | 外 型 及 安 装 尺 寸 | 机组 重量 (Kg) | ||||||||||||||||||

| A | L, | L₂ | L, | L | a | f | X | L. | B/B₂ | B₂ | B, | h, | h₂/h₂ | h, | H | H, | H₂ | n-d | |||

| IH50-125-250 | YB160M-4/11 | 110 | 1270 | 225 | 840 | 655 | 140 | 530 | 140 | 1465 | 255/240 | 540 | 490 | 250 | 385/485 | 30 | 410 | 765 | 735 | 4-φ24 | |

| YB160L-4/15 | 1420 | 250 | 940 | 695 | 1505 | 610 | 550 | 40 | 430 | 785 | 755 | 4-φ28 | |||||||||

| YB180M-4/18.5 | 730 | 1540 | 285/240 | 430/525 | 775 | ||||||||||||||||

| YB180L-4/22 | 750 | 1560 | |||||||||||||||||||

| YB200L-4/30 | 803 | 1613 | 310/290 | 475/590 | 820 | ||||||||||||||||

| YB225S-4/37 | 845 | 1655 | 345/290 | 530/615 | |||||||||||||||||

| IH150-125-315 | YB180M-4/18.5 | 130 | 1620 | 290 | 1060 | 730 | 140 | 530 | 140F | 1540 | 285/240 | 660 | 600 | 280 | 430/525 | 40 | 480 | 835 | 825 | 4-φ28 | |

| YB180L-4/22 | 750 | 1560 | |||||||||||||||||||

| YB200L-4/30 | 803 | 1613 | 310/290 | 470/590 | 870 | ||||||||||||||||

| YB225S-4/37 | 840 | 1650 | 345/290 | 530/615 | |||||||||||||||||

| YB225M-4/45 | 870 | 1680 | |||||||||||||||||||

| YB250M-4/55 | 935 | 1745 | |385/330 | 575/740 | 970 | ||||||||||||||||

| IH150-125-400 | YB200L-4/30 | 110 | 1620 | 290 | 1200 | 803 | 140 | 530 | 140 | 1613 | 310/290 | 660 | 600 | 315 | 475/590 | 40 | 515 | 915 | 905 | 4-φ28 | |

| YB225S-4/37 | 845 | 1655 | 325/290 | 530/615 | |||||||||||||||||

| YB225M-4/45 | 870 | 1680 | |||||||||||||||||||

| YB250-4/55 | 935 | 1745 | 385/330 | 575/740 | 1005 | ||||||||||||||||

| YB280S-4/75 | 1820 | 320 | 1200 | 1010060 | 1820 | 410/330 | 730 | 670 | 640/800 | 1035 | |||||||||||

| YB280M-4/90 | 1870 | ||||||||||||||||||||

| IH200-150-250 | YB180L-4/22 | 130 | 1620 | 290 | 1060 | 750 | 160 | 530| | 180 | 1620 | 285/240 | 660 | 600 | 280 | 430/525 | 40 | 480 | 855 | 825 | 4-φ28 | |

| YB200L-4/30 | 803 | 1673 | 310/290 | 475/590 | 870 | ||||||||||||||||

| YB225S-4/37 | 840 | 1710 | 345/290 | 530/615 | |||||||||||||||||

| YB225M-4/45 | 870 | 1740 | |||||||||||||||||||

| YB250M-4/55 | 935 | 1805 | 385/330 | 575/740 | 970 | ||||||||||||||||

| YB280S-4/75 | 1820 | 320 | 1200 | 010 | 1880 | 410/330 | 730 | 670 | 640/800 | 1000 | |||||||||||

| IH200-150-315 | YB200L-4/30 | 130 | 1820 | 320 | 1200 | 803 | 160 | 670 | 180 | 1813 | 310/290 | 730 | 670 | 315 | 475/590 | 40 | 515 | 915 | 905 | 4-φ28 | |

| YB225S-4/37 | 845 | 1855 | 345/290 | 530/615 | |||||||||||||||||

| YB225M-4/45 | 870 | 1880 | |||||||||||||||||||

| YB250M-4/55 | 935 | 1945 | 385/330 | 575/740 | 1005 | ||||||||||||||||

| YB280S-4/75 | 0101060 | 20202070 | 410/330 | 640/800 | 1035 | ||||||||||||||||

| YB280M-4/90 | |||||||||||||||||||||

| IH200-150-400 | YB250M-4/55 | 130 | 1820 | 1200 | 1200 | 93510101060 | 160 | 670 | 180 | 1945 | 385/330 | 730 | 670 | 315 | 575/740 | 40 | |515 | 965 | 1005 | 4-φ28 | |

| YB280S-4/75 | 20202070 | 410/330 | 640/800 | 1035 | |||||||||||||||||

| YB280M-4/90 | |||||||||||||||||||||

IH不锈钢离心泵的安装

1 开箱后检查泵和电机,如果证实没有任何因装、卸和运输过程中造成的损坏和紧固连接件松动,泵的进出口封盖完好,没有尘土,污物等进入泵内,则可不必重新拆卸和装配,直接送到使用现场去安装。

2 安装泵的基础平面应用水平仪找平,待基础水泥凝固后,将泵安装在基础上,并用水平仪检查泵和电机轴的水平情况,如不水平,应用垫铁调正,直到水平为止。然后通过灌浆孔

用水泥浇灌底座和地脚螺栓孔眼。

3 水泥干固后,应检查底座和地脚螺栓孔眼是否松动,合适后拧紧地脚螺栓,重新检查水平度。

4 在电机、泵和底座重新安装的情况下,应严格检查泵轴和电机轴的同心度。测量联轴器的外围上下左右的差别不得超过0.1mm,两联轴器端面间隙一周上最大和最小的间隙不超过0.3mm.

5 泵的吸入管路和压出管路应有各自的支架,不允许管路的重量直接由泵来承受,以免把泵压坏。

6 泵的安装位置高于液面(在泵的吸程允许范围内)时,应在吸入管路端部装上底阀,并在排出管路上设置灌液螺孔或阀门,供起动前灌泵之用。泵的安装位置低于液面( 灌注情况)时,应在泵吸入管路上装控制阀门过滤装置,以防异物吸入泵内。