您所在的位置:

- 上海美言壹泵阀有限公司

- 全国销售热线:

+86 21 5640 2009 - 水泵客服电话:

+86 138 1691 3072 - 阀门客服电话:

+86 1381 6913 072 - 企业电子邮箱:

my1pv@1bengfa.com

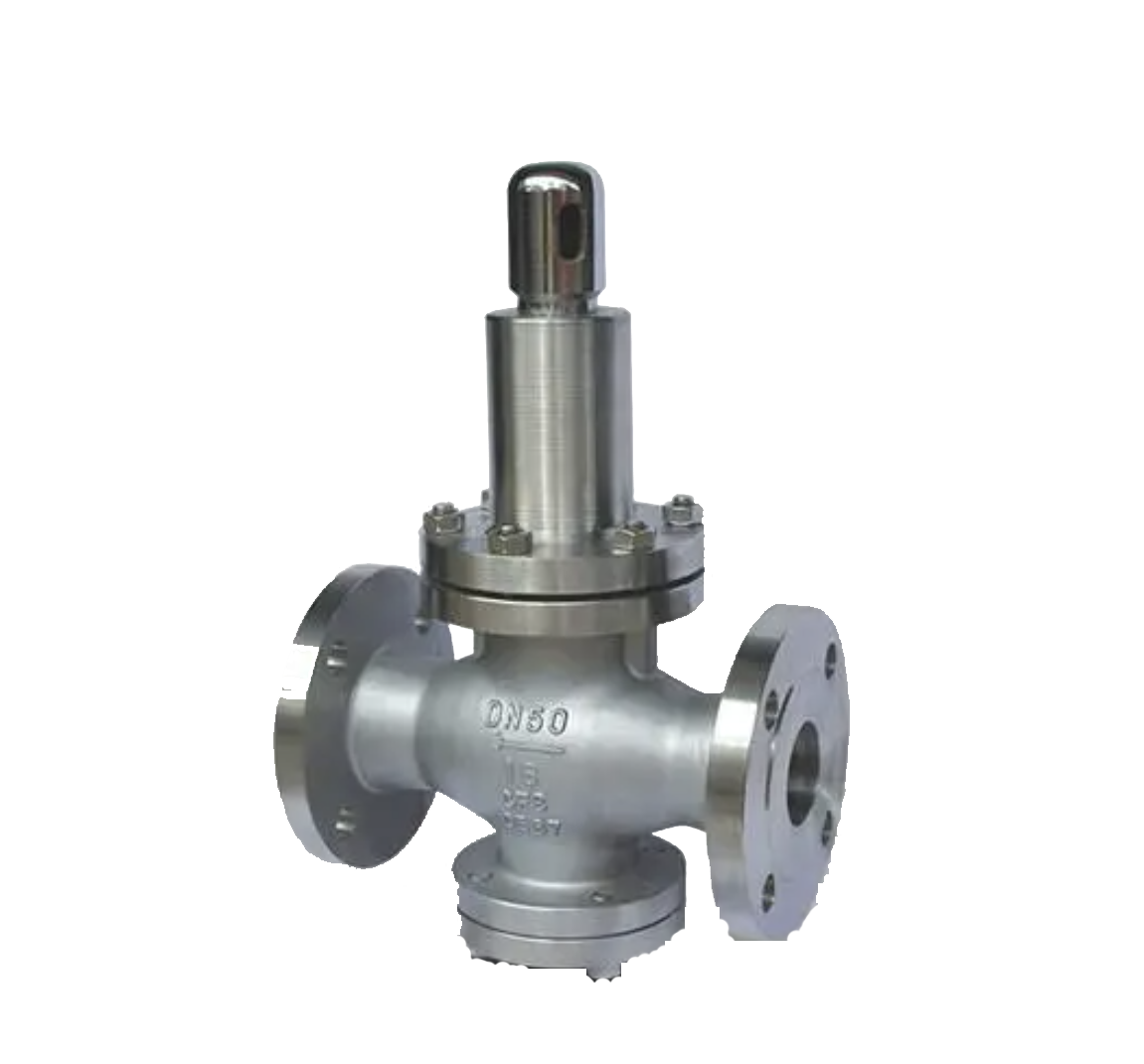

A42Y/H型高压全封闭全启式安全阀

- 品牌:壹泵阀

- 型号:A42Y-160/320/400C/P/R

- 压力/扬程:PN160-PN400

- 工作温度:≤200℃

- 连接方式:法兰

- 产品名称:A42Y/H型高压全封闭全启式安全阀

- 通径/流量:DN15-DN50

- 材质:铸钢、不锈钢、锻钢、锻不锈钢

- 驱动方式:弹簧全启式式、全封闭式

- 适用范围:水、空气、蒸汽等液体、气体。

- 产品概述

- 性能参数

- 尺寸重量

42Y-160/320/400C/P/R型高压全封闭全启式安全阀

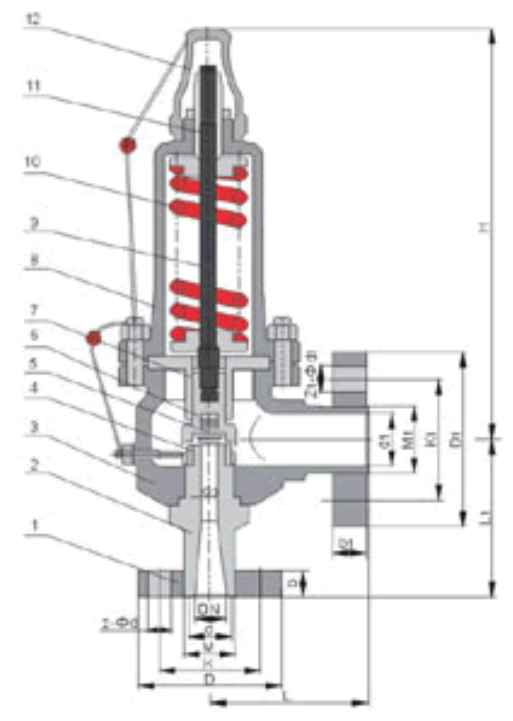

42Y-160/320/400C/P/R型高压全封闭全启式安全阀适用于工作温度≤200℃的空气、氨氢混合气等介质的设备和管路上。42Y-160/320/400C/P/R型高压全封闭全启式安全阀适用于工作温度≤200℃有腐蚀性介质的设备和管路上,作为超压保护装置。以上型号的阀门连接法兰按JB/T2769-92的标准。全启式安全阀是指当阀芯升高到与阀座的环形面积相当于阀座内径面积时(升高的高度×阀芯密封面的周长所产生的面积=阀芯密封面的面积),就是全部开启了;其典型特征是出口口径大于进口口径。准确型号包括:A42Y-160C、A42Y-160P、A42Y-160R,A42Y-320C、A42Y-320P、A42Y-320R,A42Y-400C、A42Y-400P、A42Y-400R,A42H-160C、A42H-160P、A42H-160R,A42H-320C、A42H-320P、A42H-320R,A42H-400C、A42H-400P、A42H-400R等安全阀型号。

42Y-160/320/400C/P/R型高压全封闭全启式安全阀也称封闭式安全阀,封闭式安全阀的结构特点是安全阀电机与管路相连,形成独立的密闭系统。压力升高使管路内介质增多,接触面积增大,自密闭系统内介质泄出的流量增多使阀门开启面积增大,导致阀门开启压力降低。封闭式安全阀:一般用于对介质的污染和泄漏要求较高的场合,如制药厂、食品厂等行业。封闭式安全阀的缺点是由于阀门与管路相连的设计,使其在安装、维护、更换阀门时需要停机处理,工作效率较低。

42Y-160/320/400C/P/R主要零部件材料 Materials for main parts

| NO. | 零件名称Name of part | A42Y-160 A42Y-320材料 Materials | A42Y-160P A42Y-320P材料 Materials | A42Y-160R A42Y-320R材料 Materials |

| 1 | 法兰 Flange | 35/35CrMoA | 2Cr13 | 1Cr18Ni12Mo2Ti |

| 2 | 阀 座 Nozzle | 2Cr13 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 3 | 阀 体 Body | 40 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 4 | 调节圈 Adjusting ring | 2Cr13 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 5 | 阀 瓣 Disc | 2Cr13 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 6 | 反冲盘 Disc holder | 2Cr13 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 7 | 导向套 Guide sleeve | 2Cr13 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 8 | 阀 盖 Bonnet | ZG230-450 | ZG230-450 | ZG230-450 |

| 9 | 阀 杆 Stem | 2Cr13 | 1Cr18Ni9Ti | 1Cr18Ni9Ti |

| 10 | 弹 簧 Spring | 50CrVA | 50CrVA包覆氟塑料 Coated Teflon | 50CrVA包覆氟塑料 Coated Teflon |

| 11 | 调整螺杆Adjusting bolt | 45 | 2Cr13 | 2Cr13 |

| 12 | 阀帽 Cap | ZG200-400 | ZG200-400 | ZG200-400 |

| 密封面材料 Sealing surface of material | 堆焊Co基硬质合金 Depositing stellite | |||

42Y-160/320/400C/P/R外形尺寸和连接尺寸 Dimeasions(mm)

| 型号Type | 公称通径(DN) | do | d | M | K | D | Z-Фd | b | d1 | M1 | K1 | D1 | Z1-Фd1 | b1 | L | L1 | H |

| A42Y-160 | 15 | 8 | 20 | M24×2 | 60 | 95 | 3-18 | 20 | 29 | M42×2 | 80 | 115 | 4-18 | 22 | 95 | 100 | 220 |

| 20 | 8 | 27 | M33×2 | 68 | 105 | 3-18 | 20 | 29 | M42×2 | 80 | 115 | 4-18 | 22 | 95 | 100 | 220 | |

| 25 | 14 | 28 | M33×2 | 68 | 105 | 3-18 | 20 | 50 | M64×3 | 115 | 165 | 6-26 | 32 | 150 | 150 | 280 | |

| 32 | 15 | 37 | M42×2 | 80 | 115 | 4-18 | 22 | 50 | M64×3 | 115 | 165 | 6-26 | 32 | 150 | 150 | 390 | |

| 40 | 20 | 47 | M52×2 | 115 | 165 | 6-26 | 28 | 65 | M80×3 | 145 | 200 | 6-29 | 40 | 180 | 180 | 495 | |

| 50 | 25 | 59 | M64×3 | 115 | 165 | 6-26 | 32 | 80 | M100×3 | 170 | 225 | 6-33 | 50 | 165 | 165 | 400 | |

| A42Y-320 | 15 | 8 | 27 | M33×2 | 68 | 105 | 3-18 | 20 | 29 | M42×2 | 80 | 115 | 4-18 | 22 | 95 | 100 | 220 |

| 20 | 8 | 30 | M33×2 | 75 | 110 | 3-18 | 22 | 29 | M42×2 | 80 | 115 | 4-18 | 22 | 95 | 100 | 220 | |

| 25 | 14 | 35 | M42×2 | 80 | 115 | 4-18 | 22 | 50 | M64×3 | 115 | 165 | 6-26 | 32 | 150 | 150 | 280 | |

| 32 | 15 | 41 | M48×2 | 95 | 135 | 4-22 | 25 | 50 | M64×3 | 115 | 165 | 6-26 | 32 | 150 | 150 | 390 | |

| 40 | 20 | 58 | M64×3 | 115 | 165 | 6-26 | 32 | 65 | M80×3 | 145 | 200 | 6-29 | 40 | 180 | 180 | 495 | |

| 50 | 25 | 70 | M80×3 | 145 | 200 | 6-29 | 40 | 80 | M100×3 | 170 | 225 | 6-33 | 50 | 165 | 165 | 400 | |

| A42Y-400 | 32 | 15 | 41 | M48×2 | 95 | 135 | 4-22 | 25 | 50 | M64×3 | 115 | 165 | 6-26 | 32 | 150 | 150 | 397 |